1. Confirming Technical Requirements Before Contacting Manufacturers

Before you reach out to any factory, you need to lock down clear, technical requirements. Manufacturers work fastest and most accurately when buyers provide precise data upfront. This step directly affects coating quality, color consistency, lead time, and final cost—especially for architectural-grade PVD stainless steel sheets used in visible applications like ceilings, wall panels, elevator cladding, and decorative façades.

1.1 Selecting Stainless Steel Grade Suitable for PVD Coating

Not all stainless steel grades behave the same during PVD coating. Chemical composition, surface stability, and corrosion resistance all influence how well the coating bonds and how long it performs in real projects. For most architectural uses, buyers specify decorative PVD stainless steel sheet based on the environment rather than price alone.

In real-world projects—such as hotel lobby wall panels or shopping mall ceilings—grade selection determines whether the surface stays uniform after years of lighting exposure and daily cleaning. Indoor projects often prioritize surface consistency, while exterior or semi-outdoor spaces demand stronger corrosion resistance.

| Stainless Steel Grade | Typical Application Scenarios | PVD Coating Compatibility |

|---|---|---|

| 201 | Indoor decorative panels, low humidity areas | Acceptable for indoor PVD use |

| 304 | Commercial interiors, ceilings, wall cladding | Excellent adhesion and color stability |

| 316 | Coastal buildings, exterior façades, humid zones | Best corrosion resistance for PVD |

If you do not specify the grade clearly, factories may default to the lowest-cost option, which can lead to premature discoloration or surface issues after installation.

1.2 Defining Sheet Thickness, Size Tolerances, and Flatness Standards

Thickness and flatness directly affect fabrication accuracy. When architects use stainless steel panels for large ceiling grids or laser-cut partitions, even slight warping becomes visible under lighting. This is why experienced buyers define thickness and tolerance ranges before asking for quotes.

In practice, commercial ceiling systems often use sheets between 0.8 mm and 1.2 mm, while feature walls or rigid panels may require thicker material. If your project involves bending, folding, or CNC cutting, tolerance control becomes even more critical. Flat sheets reduce installation time and prevent alignment issues on site, especially for modular architectural systems made from metal stainless steel sheet.

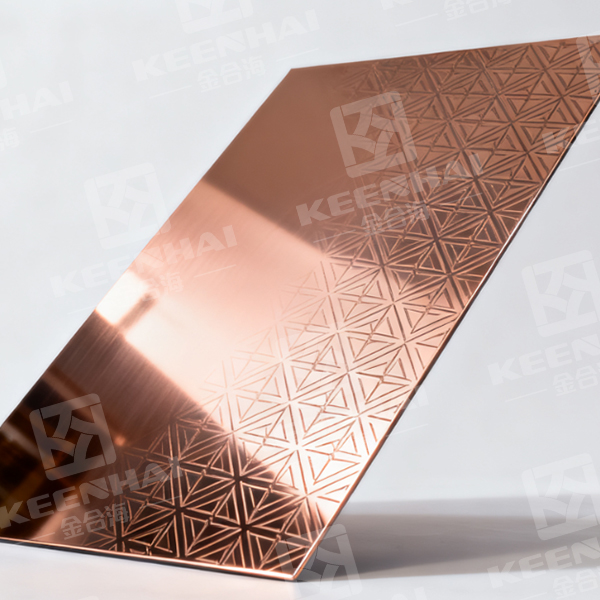

1.3 Choosing PVD Color, Coating Type, and Surface Finish

Color selection goes far beyond aesthetics. Different PVD colors react differently under artificial and natural light. For example, champagne gold in a hotel corridor looks warmer under 3000K lighting, while titanium black in office ceilings emphasizes sharp, modern lines.

When discussing finishes, buyers usually choose between mirror, brushed, bead-blasted, or patterned surfaces. Surface finish affects scratch visibility, fingerprint resistance, and color depth. In retail interiors, brushed finishes hide wear better, while mirror finishes dominate luxury spaces but demand higher handling standards.

For decorative wall panels or feature ceilings made from stainless steel metal plate, always confirm:

-

Exact color name or sample reference

-

Coating thickness requirement

-

Surface preparation method before coating

Verbal color names alone are not sufficient—visual samples prevent costly misunderstandings.

1.4 Determining Quantity, MOQ, and Usage Scenarios

Manufacturers price orders based on batch efficiency. Small orders often cost more per sheet because PVD coating requires setup calibration. That is why most factories define a minimum order quantity (MOQ) even for customized colors or finishes.

Before confirming quantity, map out where each panel will be used:

-

High-visibility areas (lobbies, showrooms, elevator interiors)

-

Standard areas (corridors, office ceilings)

-

Backup or replacement panels

This approach avoids under-ordering and color mismatch across production batches. For projects involving steel sheet stainless components across multiple zones, ordering everything in one batch ensures consistent color tone and surface texture, which architects and contractors value highly.

2. Identifying Qualified PVD Stainless Steel Sheet Manufacturers

At this stage, buyers should evaluate manufacturers as technical service providers, not as sellers. A qualified supplier proves capability through process control, documentation, and execution consistency, especially when producing architectural-grade PVD Stainless Steel Sheet used in visible, high-standard environments.

2.1 Evaluating In-House PVD Coating Capabilities

Manufacturers that operate in-house PVD coating lines maintain direct control over color consistency, coating thickness, and adhesion stability. This control becomes critical when panels install side by side under strong lighting, such as ceilings, elevator interiors, or wall cladding systems.

When reviewing a factory’s capability, focus on three operational indicators:

-

Vacuum chamber size that matches your maximum sheet dimensions without jointing

-

Target material options that support stable decorative colors across batches

-

Process repeatability controls that limit color deviation during mass production

If a manufacturer cannot explain these controls clearly, expect visible variation once panels reach the site, especially in large-area installations.

2.2 Verifying Material Certifications and Quality Control Systems

Qualified manufacturers treat documentation as part of production, not an afterthought. Buyers should request traceable material records that link stainless steel grade, coating process, and inspection results to each batch.

For commercial projects, certification gaps often lead to rejection during site inspection. Factories with structured quality systems identify flatness issues, surface defects, and coating irregularities before packing, reducing rework and project delays.

2.3 Assessing Export Experience and Custom Order Handling

Export experience reflects how well a manufacturer handles non-standard requirements and real-world constraints. International projects introduce longer transit times, stricter packaging demands, and higher expectations for labeling accuracy.

For customized architectural orders, capable manufacturers can:

-

Translate drawings into production-ready specifications

-

Group panels by zone or installation sequence

-

Align production schedules with shipping timelines

These practices reduce confusion during installation and prevent costly on-site adjustments.

2.4 Comparing Factory Scale, Equipment, and Production Capacity

Factory scale affects delivery reliability. Very small workshops struggle with schedule stability, while oversized plants may deprioritize customized architectural orders. Balanced capacity with specialized equipment delivers the most consistent results.

When comparing manufacturers, examine:

-

Number of active PVD coating lines

-

Monthly output capacity by thickness range

-

Integration of cutting, bending, and surface finishing processes

Production alignment matters more than sheer volume, especially for decorative stainless steel projects that demand uniform appearance across large areas.

3. Requesting Quotes and Samples from Manufacturers

Once technical requirements are fixed, the next step focuses on commercial accuracy and physical verification. Quoting errors and sample mismatches usually come from incomplete RFQs or vague expectations. This stage determines whether pricing stays stable, samples match mass production, and timelines remain realistic.

3.1 Preparing a Professional RFQ with Complete Specifications

A professional RFQ removes assumptions. Manufacturers price accurately only when specifications leave no gaps. When requesting quotes for PVD Stainless Steel Sheet, include all production-critical details in one document instead of scattered emails.

A complete RFQ should clearly list:

-

Stainless steel grade and surface condition before coating

-

Sheet thickness, finished size, and flatness tolerance

-

PVD color reference and surface finish type

-

Quantity per specification and total order volume

-

Packaging method and destination port

The more precise the RFQ, the fewer pricing revisions later. Factories prioritize RFQs that show technical clarity because they reduce production risk and internal rework.

3.2 Understanding Unit Pricing, Coating Costs, and Volume Discounts

Pricing consists of material cost, surface preparation, PVD coating, handling, and packaging. Buyers often compare quotes without understanding how volume affects coating efficiency. Larger batches stabilize chamber parameters, which lowers per-sheet cost.

Below is a simplified pricing logic used by most manufacturers:

| Order Volume | Unit Price Trend | Cost Driver Explanation |

|---|---|---|

| Low quantity | Hoër | Coating setup and calibration spread over fewer sheets |

| Medium batch | Stable | Balanced coating efficiency and material utilization |

| Large batch | Laer | Optimized vacuum cycles and reduced handling cost |

Always confirm whether pricing includes color development, testing, and re-coating allowances. These details explain why quotes for similar-looking sheets can vary significantly.

3.3 Requesting Physical Samples and Color Consistency Checks

Visual confirmation matters more than written descriptions. Digital photos never reflect real coating depth, especially under architectural lighting. When requesting samples, specify production-grade samples, not lab test pieces.

To avoid mismatch risks, request:

-

Samples produced on the same coating line planned for mass production

-

Color samples checked under both natural and artificial light

-

Surface finish samples showing scratch and fingerprint behavior

A valid sample represents repeatability, not just appearance. If the supplier cannot guarantee batch-to-batch consistency, expect visible variation after installation.

3.4 Clarifying Lead Time for Sampling and Mass Production

Lead time affects project sequencing. Sampling and mass production follow different timelines, and buyers must confirm both early.

Clarify the schedule in this order:

-

Sample production lead time after RFQ confirmation

-

Approval window for color and surface finish

-

Mass production lead time after sample sign-off

-

Buffer time for inspection and packing

Clear timeline alignment prevents rushed coating cycles, which often cause color deviation or surface defects in decorative stainless steel applications.

4. Confirming Order Details and Production Specifications

Once pricing and samples are approved, this stage determines whether production delivers exactly what was agreed—or quietly drifts off-spec. At this point, ambiguity becomes risk. Clear documentation, confirmed parameters, and defined checkpoints protect both timeline and surface quality for architectural-grade PVD Stainless Steel Sheet orders.

4.1 Finalizing Technical Drawings and Written Specifications

Technical drawings translate intent into execution. Buyers should never rely on emails or verbal confirmations alone. Every critical requirement must appear in one consolidated specification set that production teams can follow without interpretation.

A complete confirmation package should include:

-

Final approved drawings with dimensions, tolerances, and bending details

-

Written specifications covering material grade, surface finish, and coating type

-

Panel identification logic for sequencing or zoning

-

Approved reference samples linked to drawing numbers

If a requirement does not appear in writing, production teams will not treat it as mandatory. This step prevents silent substitutions and ensures consistency across large panel runs.

4.2 Confirming PVD Coating Parameters and Color Approval

Color approval goes beyond visual acceptance. Buyers must confirm coating parameters that guarantee repeatability, not just appearance. This matters most in projects where panels install adjacent to each other under controlled lighting, such as hotel ceilings or elevator interiors.

Before releasing production, confirm:

-

Approved color sample ID and coating batch reference

-

Coating thickness range suitable for the selected application

-

Surface preparation method before coating

-

Acceptable color deviation range across batches

Once color approval is signed off, changes introduce cost, delay, and inconsistency. This checkpoint locks visual performance before mass production begins.

4.3 Defining Packaging Methods for Surface Protection

Packaging directly affects surface condition upon arrival. Decorative stainless steel panels suffer damage more often during packing and transit than during production. Buyers should specify packaging methods based on finish type and destination.

Key points to define clearly:

-

Protective film type and adhesion strength

-

Interleaving material between sheets

-

Pallet structure and edge protection

-

Moisture control for long-distance shipping

Packaging is part of the product, not an afterthought. Clear instructions reduce claims, rework, and installation delays.

4.4 Setting Production Schedule and Inspection Points

A realistic production schedule balances speed with coating stability. Rushed cycles increase the risk of color deviation or surface defects. Buyers should confirm inspection checkpoints before shipment, not after arrival.

A structured production timeline typically follows this sequence:

-

Drawing and specification sign-off

-

Coating trial confirmation

-

Mid-production inspection or photo verification

-

Final inspection before packing

Defined inspection points give buyers control without disrupting production flow. This approach keeps quality predictable while protecting delivery commitments.

5. Managing Payment Terms and Trade Conditions

At this stage, buyers move from evaluation to commitment. Payment terms and trade conditions define how risk, cash flow, and responsibility get shared between both sides. Clear agreements here prevent disputes later, especially when ordering customized architectural materials with long production cycles.

5.1 Common Payment Structures for Direct Manufacturer Orders

Direct factory orders usually follow standardized payment structures, but buyers should select terms that match project risk and order size. The most common structure in international manufacturing follows a staged approach:

-

Deposit paid after specification and sample approval

-

Balance settled after production completion and inspection

-

Shipment released only after payment confirmation

This structure aligns incentives on both sides. Factories secure material and production costs upfront, while buyers retain leverage until quality confirmation. For customized decorative stainless steel orders, staged payments reduce exposure without slowing production.

5.2 Selecting Incoterms for Factory-Direct Shipments

Incoterms define where responsibility transfers during shipping. Choosing the right term affects cost control, logistics coordination, and customs handling. Buyers ordering architectural stainless steel panels typically choose based on internal logistics capability.

Common selections include:

-

EXW for buyers managing full logistics

-

FOB for balanced responsibility at the port of loading

-

CIF for simplified shipping cost visibility

Incoterms should align with your internal supply chain strength, not just quoted price. Misaligned terms often create delays during customs clearance or inland transport.

5.3 Handling Currency, Bank Fees, and Transaction Timing

Currency selection impacts total landed cost. Most manufacturers quote in USD, but buyers should confirm how exchange rate fluctuations affect payment timing. Bank transfer fees, intermediary charges, and receiving bank costs can erode budget if ignored.

Best practice includes:

-

Confirming who bears intermediary bank fees

-

Aligning payment dates with production milestones

-

Locking exchange rates when possible for large orders

Small percentage differences compound quickly on large-volume architectural orders, making financial clarity as important as technical accuracy.

5.4 Reducing Payment Risk in First-Time Manufacturer Cooperation

First cooperation carries the highest financial risk. Buyers reduce exposure by structuring payments around verifiable production progress rather than trust alone. Documentation, inspection reports, and clear communication form the foundation of safe transactions.

Experienced manufacturers—such as pvdstainlesssteel—typically support transparent payment milestones, inspection coordination, and clear trade terms because predictable cooperation lowers risk for both parties. This transparency matters most when dealing with customized finishes and large panel quantities that cannot be resold easily.