Inox outperforms typical stainless steel in corrosion resistance due to its higher chromium and nickel content, which forms a self-repairing surface layer. Projects exposed to salt, humidity, or chemicals benefit significantly from inox, reducing maintenance needs over 15–20 years while maintaining structural integrity and appearance.

1. Understanding Material Inox vs Stainless Steel

Material Inox, often referred to simply as “inox,” is essentially a subset of stainless steel, prized for its high corrosion resistance and long-term durability. The term comes from the French word rustfrit, meaning “non-oxidizing,” which highlights its main advantage over ordinary steel in harsh environments. While all inox is stainless steel, not all stainless steel meets the strict composition standards that define true inox. Typically, inox includes high percentages of chromium and nickel, which form a passive layer on the surface, preventing rust and chemical degradation even in coastal or industrial applications. For instance, architects often specify Rustfrit stålplade for exterior cladding in seaside resorts because of its ability to resist salt-laden air without pitting.

1.1 Definition and Composition of Inox

Inox is a category of stainless steel with tightly controlled alloying elements. Most inox grades contain 16–20% chromium and 8–12% nickel, sometimes with added molybdenum for enhanced corrosion resistance. This composition ensures exceptional resistance to oxidation and chemical exposure, making it suitable for both architectural and industrial uses. In practical scenarios, inox is frequently used in kitchen equipment, medical instruments, and outdoor structures where both hygiene and longevity are critical.

1.2 Common Grades of Stainless Steel

Stainless steel itself comes in various grades such as 304, 316, and 430, each with unique strengths. 304 is versatile and cost-effective, 316 contains molybdenum for superior corrosion resistance, and 430 offers magnetic properties with moderate corrosion resistance. Comparing the most widely used grades:

| Grade | Chromium (%) | Nickel (%) | Key Feature | Common Application |

|---|---|---|---|---|

| 304 | 18–20 | 8–10 | Balanced corrosion & strength | Kitchen appliances, cladding |

| 316 | 16–18 | 10–14 | High corrosion resistance | Coastal architecture, chemical plants |

| 430 | 16–18 | 0 | Magnetic, lower corrosion resistance | Decorative panels, automotive trims |

This comparison helps designers and engineers choose the appropriate grade for their specific environmental and load requirements. For specialized applications like heavy-duty panels or structural frames, a SS Steel Plate might be selected due to its precise alloy composition and consistent thickness.

1.3 Key Differences in Alloying Elements

The distinction between inox and generic stainless steel largely comes down to the presence and balance of chromium, nickel, and sometimes molybdenum. Inox maintains a higher and more consistent chromium content, which ensures the formation of a uniform passive layer. This layer prevents corrosion even when the material is scratched or exposed to acidic or salty environments. For example, in a seaside hotel facade project, architects used metal inox sheets with molybdenum-enhanced composition to ensure long-term durability without frequent maintenance. Additionally, surface finishing, such as brushed or mirror polish, further enhances both aesthetics and protection, allowing designers to combine visual appeal with structural resilience.

2. Performance Comparison Between Inox and Stainless Steel

When comparing the performance of inox and standard stainless steel, the differences become clear in corrosion resistance, mechanical strength, and chemical tolerance. Inox typically exhibits superior corrosion resistance due to its higher chromium and nickel content, which forms a self-repairing passive layer on the surface. This makes inox ideal for coastal, industrial, or chemical-rich environments where ordinary stainless steel may show pitting or rust over time. For example, architects often select Metalplade i rustfrit stål for outdoor structures exposed to frequent rain and salt spray because it maintains integrity with minimal maintenance.

2.1 Corrosion and Oxidation Resistance

Inox’s enhanced chromium and nickel composition allows it to resist both uniform corrosion and localized pitting far better than generic stainless steel. Tests in coastal environments show that 316-grade inox panels can endure over 20 years without significant oxidation, whereas lower-grade stainless steel may start showing surface rust within 5–7 years under similar conditions. For long-term installations, using inox can significantly reduce repainting or replacement costs.

2.2 Mechanical Strength and Durability

Inox generally offers higher tensile and yield strength compared to many standard stainless steel grades. For instance:

| Property | Inox (316) | Common Stainless Steel (304) |

|---|---|---|

| Trækstyrke | 580 MPa | 520 MPa |

| Flydespænding | 290 MPa | 215 MPa |

| Elongation | 50% | 40% |

These differences make inox more suitable for load-bearing structures, staircases, or large exterior panels. During installation, professionals typically follow 3 key steps to maximize durability:

-

Select the appropriate inox grade based on environmental exposure.

-

Ensure proper welding techniques to prevent heat-induced corrosion.

-

Apply protective surface finishes if high aesthetic appeal is required.

2.3 Heat and Chemical Resistance

Inox performs exceptionally well under elevated temperatures and chemical exposure. It can maintain structural stability at temperatures up to 870°C in continuous service, compared to around 800°C for standard stainless steel. Additionally, inox resists acids, chlorides, and cleaning chemicals, making it ideal for industrial plants, commercial kitchens, and laboratory environments. In cases where long-term chemical resistance and hygiene are critical, specifying inox ensures both safety and longevity without frequent maintenance.

3. Cost and Fabrication Considerations

When evaluating inox versus standard stainless steel, understanding cost and fabrication factors is crucial for both architects and engineers. While inox offers superior corrosion resistance and durability, its initial material and processing costs are higher. For instance, Rustfrit stålplade used in commercial facades typically costs 15–25% more than standard 304 stainless steel due to tighter alloy tolerances and additional quality checks. However, this upfront investment often pays off over time through reduced maintenance and longer service life.

3.1 Initial Material and Processing Costs

The higher price of inox stems from its alloy composition, primarily the higher content of chromium and nickel, which increases raw material expenses. Processing inox also demands specialized equipment and precision techniques:

-

Cutting must use carbide-tipped or laser tools to avoid deformation.

-

Welding requires controlled heat input to maintain corrosion resistance.

-

Surface finishing, such as polishing or brushing, must be carefully executed to preserve both appearance and protective passive layer.

3.2 Workability and Forming Challenges

Inox is harder and less ductile than softer stainless steel variants, making forming operations slightly more challenging. Bending, stamping, or rolling inox requires careful adjustment of pressure and tooling, or the metal can spring back or crack. Despite these challenges, the increased strength and corrosion resistance justify the extra effort, especially for projects exposed to harsh environmental conditions or requiring structural longevity. Using a SS Steel Plate for precision panels can simplify fabrication while maintaining the benefits of inox’s alloy properties.

3.3 Long-Term Maintenance Expenses

While inox demands higher initial costs, it often reduces long-term maintenance expenses. Facilities in coastal or industrial areas report that inox surfaces retain their corrosion resistance and appearance for 15–20 years without significant interventions, whereas ordinary stainless steel may require frequent cleaning, passivation, or partial replacement. By investing in inox upfront, project owners can minimize downtime and avoid repeated surface repairs, ultimately lowering the total cost of ownership.

4. Aesthetic and Design Advantages

Material inox not only excels in performance but also provides outstanding aesthetic versatility. Its ability to maintain a pristine surface under harsh conditions makes it a favorite among architects and designers. For instance, large commercial facades or urban art installations often leverage Rustfrit stålplade due to its consistent luster and modern appeal. By combining structural reliability with visual elegance, inox allows designers to achieve both functional and stylistic goals in one material.

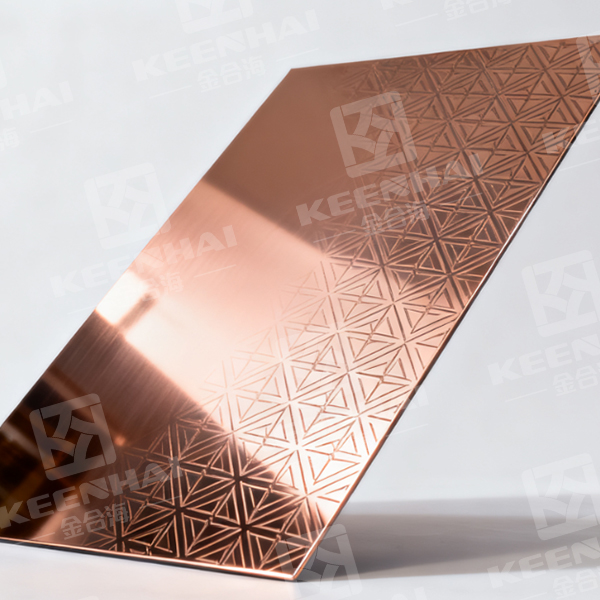

4.1 Surface Finish Options and Visual Appeal

Inox comes in multiple surface finishes such as brushed, mirror-polished, matte, or patterned textures, which can dramatically affect the perception of a building. Architects typically follow 3 steps to select and apply finishes for optimal effect:

-

Determine exposure conditions to select a finish that resists oxidation and fingerprints.

-

Choose the appropriate polishing or brushing technique to highlight or soften reflections.

-

Apply protective coatings if additional durability or color retention is required.

Brushed inox panels are especially popular in urban interiors and high-traffic areas because they hide minor scratches while maintaining a sleek, professional look.

4.2 Versatility in Modern Architectural Applications

Inox adapts easily to both contemporary and industrial design concepts. Designers frequently incorporate it in curved facades, stair railings, elevator claddings, and decorative partitions. Its ability to be precisely cut, bent, or laser-etched allows for creative freedom without compromising durability. Using a Metal rustfrit stålplade in these applications ensures both visual consistency and corrosion resistance, making it suitable for indoor and outdoor projects.

4.3 Color and Coating Possibilities

Advanced coating techniques, including PVD (Physical Vapor Deposition) or electrochemical coloring, expand inox’s design potential. Designers can now achieve gold, bronze, black, or even iridescent finishes, giving architects the ability to integrate inox seamlessly into various design palettes. Proper coating application typically involves:

-

Surface preparation to remove impurities.

-

Uniform deposition of the chosen coating.

-

Quality inspection to ensure color consistency and adhesion.

This combination of color, texture, and finish options makes inox a material of choice for premium architectural and decorative applications, providing both longevity and striking aesthetics.

5. Application-Specific Recommendations

Material inox stands out in a variety of applications where performance, durability, and aesthetics are critical. Its versatility allows architects, engineers, and designers to choose inox for both functional and decorative purposes, ensuring long-term value across different environments and use cases.

5.1 High-Humidity or Coastal Environments

Inox is particularly suitable for areas with high humidity or salt exposure, such as coastal buildings, waterfront structures, and outdoor marine equipment. Its high chromium and nickel content forms a self-protecting oxide layer, preventing rust and corrosion. For installation:

-

Select the correct grade of inox for environmental conditions (e.g., 316 for saltwater exposure).

-

Apply precise welding techniques to maintain corrosion resistance.

-

Inspect and clean surfaces periodically to avoid buildup of abrasive salt deposits.

These steps ensure structural integrity even in harsh conditions, providing decades of worry-free performance.

5.2 Industrial and Commercial Use Cases

Inox excels in factories, warehouses, commercial kitchens, and large infrastructure projects. Using Rustfrit stålplade eller Metal rustfrit stålplade for machinery panels, storage racks, and railings ensures high wear resistance and minimal maintenance. Key installation steps include:

-

Measure and cut sheets with high-precision tools.

-

Employ specialized welding and joining methods to maintain durability.

-

Apply protective finishes where chemical or mechanical stress is high.

This approach maximizes lifespan and safety, making inox an economical choice over time despite higher upfront costs.

5.3 Residential or Decorative Installations

For homes and decorative applications, inox delivers both style and function. It is used for stair railings, kitchen backsplashes, furniture accents, and facades. Benefits include easy cleaning, fingerprint resistance, and customizable finishes. Installation typically involves:

-

Measuring panels accurately to fit design specifications.

-

Using proper mounting hardware to avoid surface deformation.

-

Applying finishing techniques such as brushing or PVD coating to enhance aesthetic appeal.

By following these steps, inox provides a modern, durable, and low-maintenance solution suitable for residential and decorative contexts.

When deciding whether inox is better than standard stainless steel, it ultimately depends on your project requirements. Inox offers superior corrosion resistance, higher strength, and longer-lasting durability, making it ideal for coastal buildings, industrial sites, and high-humidity environments. Its aesthetic versatility with finishes and coatings also makes it a designer favorite.