Material Inox Sheets come in standard sizes like 4'x8' and 4'x10', but custom sizes are also available for specific applications. The thickness typically ranges from 0.3mm to 6mm, with thinner sheets used for decorative purposes and thicker ones for industrial uses. Selecting the right size and thickness ensures durability, strength, and the perfect fit for your project.

1. Understanding Material Inox Sheets

1.1 What is Inox (Stainless Steel) Sheet?

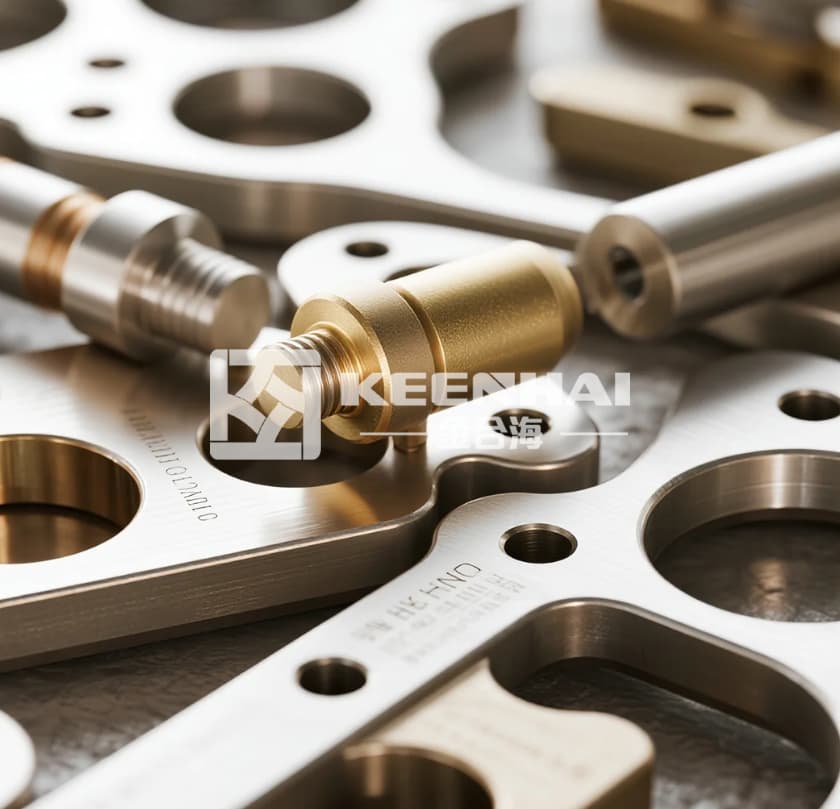

Inox, or stainless steel, is an alloy primarily made of iron, chromium, and other elements like nickel. This combination gives inox its notable korrosionsbestandighed and durability. A rustfri stålplade is a thin, flat piece of inox, commonly used in a variety of applications that require both strength and aesthetic appeal. Inox sheets come in a variety of grades, with different alloy compositions, making them suitable for different environments and uses. For example, in industrial applications where durability is essential, a SS steel plate may be chosen for its enhanced strength. Stainless steel sheets, known for their ability to withstand harsh environmental conditions, are ideal for architectural projects, automotive parts, and food processing equipment.

1.2 Key Properties of Inox Sheets

Inox sheets are highly valued for their korrosionsbestandighed, which is primarily due to the formation of a protective chromium oxide layer on the material’s surface. This layer prevents the material from rusting or corroding, even when exposed to moisture or other environmental factors. Additionally, inox sheets are known for their high tensile strength og resilience, making them suitable for applications requiring both structural integrity and a sleek finish. Another important property is inox’s temperature resistance, which allows it to maintain its strength and appearance in high-temperature environments. In some cases, Stainless Steel Metal Plates are used for projects that require higher thickness or special finishes. These properties make inox sheets versatile and ideal for applications ranging from construction to heavy-duty industrial use.

1.3 Applications of Inox Sheets

Inox sheets are widely used across several industries due to their unique properties. In construction, inox sheets are commonly used for exterior cladding og roofing, as they can withstand exposure to the elements without deteriorating. Their aesthetic appeal, combined with their strength, makes them a popular choice for modern architectural designs. In the food industry, inox sheets are frequently used for countertops, sinks, og processing equipment, where hygiene and resistance to corrosion are crucial. The automotive industry also utilizes inox sheets for parts such as body panels og exhaust systems, where both durability and heat resistance are required. With their ability to perform in tough conditions, inox sheets are a key material in both industrial and commercial applications.

2. Inox Sheet Sizes

2.1 Standard Sizes of Inox Sheets

Inox sheets are commonly available in several standard sizes, which cater to the needs of most industries. The most common dimensions are 4 feet by 8 feet (1.2 meters by 2.4 meters) and 5 feet by 10 feet (1.5 meters by 3 meters). These sizes are often used for cladding, roofing, og general fabrication, providing a versatile and cost-effective solution for many applications. Standard inox sheet thicknesses typically range from 0.3 mm til 6 mm, though heavier gauges may be necessary for more demanding structural applications. For example, thicker sheets are typically chosen for applications like industrial equipment or architectural facades, where additional strength and durability are needed. If thicker material is required, Stainless Steel Metal Plates are a suitable option for projects that need extra strength. Whether you’re working on an exterior renovation or a specialized industrial project, standard inox sheet sizes are designed to offer a flexible solution.

2.2 Custom Sizes for Specific Applications

For specialized projects, custom inox sheet sizes are available to meet unique specifications. Industries such as automotive manufacturing, construction, og kitchen equipment often require non-standard dimensions to ensure perfect fitment for specific applications. Custom sizes can include thin sheets for intricate designs or large panels for industrial applications. One example is the food processing industry, where inox sheets of custom sizes are cut to fit custom-made machinery and equipment surfaces. Custom inox sheets can also be tailored to meet specific thickness requirements, ensuring optimal performance under varying load and pressure conditions. When choosing custom inox sheets, it’s important to collaborate with a supplier who offers precise cutting services to ensure accuracy and minimize waste. This flexibility in size makes inox sheets an indispensable material for sectors that require both functional and aesthetic flexibility.

3. Inox Sheet Thickness

3.1 Common Thicknesses for Inox Sheets

Inox sheets come in a wide range of thicknesses to suit different industrial and commercial applications. The most common thicknesses range from 0.3 mm til 6 mm, with variations available for both light-duty og heavy-duty uses. For example, thin inox sheets (around 0.3 mm to 1 mm) are typically used in applications like decorative panels eller kitchen equipment, where flexibility and aesthetic appeal are required. For more robust uses, such as structural components og exterior cladding, thicker sheets (2 mm to 6 mm) are more appropriate. The thickness directly affects the sheet’s strength og resilience, with thicker sheets being more durable and capable of withstanding greater pressure. When heavier sheets are needed, Stainless Steel Metal Plates are often used for their enhanced strength and durability in challenging environments.

3.2 Choosing the Right Thickness for Your Project

Choosing the right thickness for your inox sheet project depends largely on the material’s intended use. To make the best selection, consider the application environment, strength requirements, og aesthetic considerations. For example, in architectural design, where both visual appeal and structural integrity are crucial, mid-range thicknesses (1 mm to 3 mm) are often ideal. For industrial equipment eller machinery, thicker inox sheets (above 3 mm) are preferred to ensure maximum durability and resistance to wear and tear. Additionally, if you’re working with custom-sized inox sheets, it’s important to factor in the load-bearing capacity og external conditions, such as exposure to weather or chemicals, to ensure the material can perform over time. Always consult with a supplier to determine the best thickness based on your specific project needs.

4. Applications of Inox Sheets

4.1 Industrial Uses of Inox Sheets

Inox sheets are widely used across various industrial sectors due to their strength, holdbarhed, og modstandsdygtighed over for korrosion. In industries like automotive manufacturing, chemical processing, og food production, inox sheets are favored for their ability to withstand extreme conditions. For example, in chemical plants, inox sheets are used in equipment surfaces, tanks, og pipes, where resistance to corrosion is critical. Similarly, in automotive production, inox sheets are employed for exhaust systems, body panels, and other components that need to endure heat and wear. Due to their non-reactivity, inox sheets are also used in food processing industries, where hygiene and durability are paramount. When these applications require additional strength, Stainless Steel Metal Plates are often selected for their enhanced resistance to impact and wear.

4.2 Architectural and Design Applications

In addition to industrial uses, inox sheets have become an integral material in architecture og interior design due to their aesthetic appeal og functional properties. From cladding og facades til interior wall panels, inox sheets are used to achieve sleek, modern designs with minimal maintenance. Their reflective surface also makes them a popular choice for architectural finishes, adding a contemporary look to commercial buildings, restaurants, and hotels. Moreover, inox sheets are fire-resistant and highly durable, making them a preferred material for exterior structures exposed to harsh weather conditions. The material’s formability also makes it suitable for custom designs, including architectural sculptures og art installations. Whether it’s for elevators, kitchen backsplashes, eller luxury furniture, inox sheets offer both visual appeal og long-term functionality.

5. Factors to Consider When Selecting Inox Sheets

5.1. Environmental Conditions and Durability

When selecting inox sheets, it’s crucial to consider the environmental conditions in which the material will be used. Inox sheets are known for their korrosionsbestandighed, but the level of resistance can vary depending on the environment. For example, environments with high humidity, saltwater exposure, eller extreme temperatures may require specific grades of inox for optimal performance. In these conditions, higher-quality inox, such as 316 rustfrit stål, offers better protection against rust and corrosion. Industrial applications that involve chemicals or acidic materials, such as food processing plants eller chemical storage, may benefit from inox sheets that offer both strength og chemical resistance. Ensuring the right thickness and grade of inox sheet is critical for its long-term durability in these harsh environments. In such cases, Stainless Steel Metal Plates may also be selected for additional durability, especially in applications that experience constant wear and tear.

5.2. Cost Considerations and Quality

While inox sheets are a durable, long-lasting material, the cost of the material can vary significantly based on grade og thickness. The price of inox is influenced by factors such as the specific alloy used, the size of the sheet, and any tilpasning required. 304 rustfrit stål, for instance, is less expensive than 316 rustfrit stål, but it may not perform as well in highly corrosive environments. Therefore, balancing cost og quality is essential for making the best choice for your project. If your project demands cost-efficiency without sacrificing too much performance, Stainless Steel Sheets in the 304 grade may provide the best value for general applications. However, if you are working on a project where high performance og langsigtet holdbarhed are paramount—such as exterior cladding eller marine applications—the initial higher cost of materials like 316 rustfrit stål may be more cost-effective over time due to its extended lifespan og lower maintenance needs.