Choosing the right commercial stainless steel wine cabinets starts with evaluating storage capacity, space layout, and cabinet type. Look for suppliers who offer both standard and custom solutions, provide multi-zone temperature control, and integrate high-quality materials. Ensuring proper cooling, humidity, and display features guarantees that your cabinets protect wine quality while enhancing the environment of hotels, bars, or restaurants.

1. Key Considerations Before Purchasing

1.1 Determining Storage Capacity Requirements

When selecting a commercial wine cabinet, the first step is to accurately assess your storage needs. Count the number of bottles you intend to store and consider potential expansion. For instance, a busy hotel bar might require multiple modular cabinets to handle both red and white wines, while a boutique restaurant may need a compact setup with premium display racks.

Key factors to evaluate include:

-

Total bottle count: Standard commercial cabinets range from 50 to over 500 bottles.

-

Type of wine: Red, white, sparkling, or rare vintage collections often need separate climate zones.

-

Growth plans: Estimate storage for the next 3–5 years to avoid frequent upgrades.

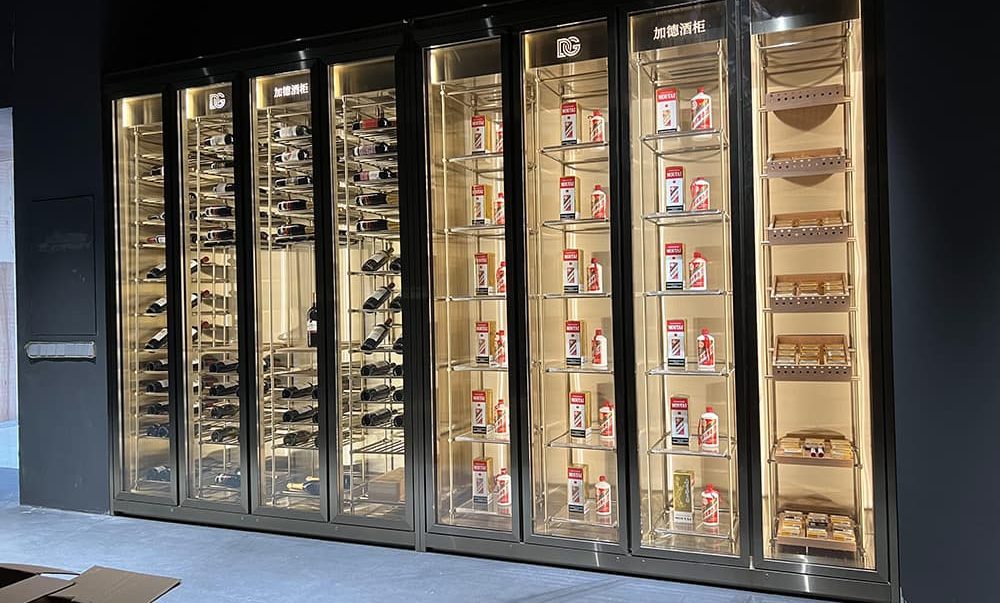

In some commercial setups, combining Commercial Wine Cabinet Stainless Steel units with open Stainless Steel Wine Racks provides flexible storage while maximizing display appeal. For example, a hotel lobby bar used a mix of enclosed cabinets for high-value wines and open racks for fast-access bottles, creating both efficiency and aesthetic impact.

1.2 Space Planning and Layout Optimization

Once capacity is determined, plan the physical layout of the wine storage area carefully. Commercial kitchens, bars, or tasting rooms often face space constraints or irregular floor plans, so cabinets must fit seamlessly without disrupting workflow.

Consider these points:

-

Foot traffic and accessibility: Ensure staff can access bottles without obstruction.

-

Cabinet alignment: Group units to maintain consistent temperature zones and avoid hot spots.

-

Integration with interior design: Stainless steel finishes, glass doors, and lighting enhance visual appeal while keeping functionality intact.

For example, a fine-dining restaurant installed Neoksidebla ŝtalo vinŝrankoj along one wall with custom overhead lighting. The configuration allowed easy bottle rotation and added a visually striking focal point in the dining area.

1.3 Budget and Cost Evaluation

Budget planning is critical in commercial wine storage, especially when balancing upfront investment and long-term operational costs. Stainless steel cabinets may have higher initial prices but offer durability, low maintenance, and better resale value.

A side-by-side comparison of typical options:

| Karakterizaĵo | Basic Stainless Steel Cabinet | Premium Commercial Wine Cabinet |

|---|---|---|

| Capacity | 50–100 bottles | 200–500+ bottles |

| Cooling Zones | Single | Multi-zone with precise temperature control |

| Materials | Standard 304 SS | 316L or PVD finish |

| Price Range | $1,500–$3,000 | $4,500–$10,000 |

| Prizorgado | Moderate | Minimal, long-term durability |

In commercial projects, investing in premium cabinets often reduces replacement frequency and operational disruptions. For instance, a bar chain chose high-end stainless steel units across five locations, avoiding repeated repairs and ensuring consistent wine preservation.

2. Cabinet Types and Configurations

2.1 Standard vs Custom Commercial Wine Cabinets

When it comes to commercial wine cabinets, choosing between standard and custom designs depends on both operational needs and space constraints. Standard cabinets are ready-made, offering a quick solution for bars, restaurants, or hotels with uniform storage requirements. They typically feature fixed dimensions, standard bottle capacity, and pre-set temperature zones.

Custom cabinets, on the other hand, provide flexibility in size, layout, and finishing options. For instance, a high-end hotel designed a custom Commercial Wine Cabinet Stainless Steel unit to fit a corner space while integrating multi-zone cooling for different wine types. This approach maximized storage capacity and matched the interior design seamlessly.

Key differences between standard and custom units:

| Karakterizaĵo | Standard Cabinets | Custom Cabinets |

|---|---|---|

| Size Options | Fixed | Tailored to space |

| Cooling Zones | Single | Multi-zone available |

| Material Finishes | Limited | Wide variety (brushed, PVD, polished) |

| Lead Time | Short | Longer due to customization |

| Cost | Moderate | Higher but long-term value |

If your venue expects variable wine types and fluctuating inventory, opting for custom units often reduces long-term operational headaches.

2.2 Integrated Wine Racks and Multi-Zone Units

Combining cabinets with integrated wine racks improves accessibility and presentation. Many commercial setups now feature modular systems where enclosed cabinets are paired with open Neoksidebla Ŝtalo Vina Rack Kabineto units for display purposes.

Benefits include:

-

Separation of premium wines and fast-access bottles, ensuring optimal rotation.

-

Efficient use of space by stacking racks above or beside climate-controlled cabinets.

-

Multi-zone temperature management, allowing reds, whites, and sparkling wines to coexist in one system.

For example, a restaurant chain installed cabinets with three distinct temperature zones, each connected to display racks. This allowed staff to serve wines immediately while maintaining precise storage conditions.

2.3 Door Styles, Glass Panels, and Display Options

Door configuration and display options impact both visual appeal and functionality. Commercial wine cabinets offer a range of doors: full glass, half-glass, solid stainless steel, or hybrid combinations.

Considerations when selecting doors and panels:

-

Glass type: Tempered or low-iron glass enhances clarity and durability.

-

Lighting integration: LED or accent lighting inside the cabinet improves visibility and presentation.

-

Accessibility: Sliding doors vs. hinged doors depend on available space and operational workflow.

In practice, a hotel lobby bar used Neoksidebla ŝtalo vinŝrankoj with full-glass doors and interior LED strips. The design highlighted premium bottles, encouraged customer interaction, and allowed staff to quickly locate and retrieve bottles during peak hours.

3. Materials, Grades, and Surface Finishes

3.1 Stainless Steel Grades and Corrosion Resistance

Elektante la ĝustan stainless steel grade is crucial for long-lasting commercial wine cabinets. The most common grades include 304, 316, and 430 stainless steel. 304 neoksidebla ŝtalo offers excellent corrosion resistance and is ideal for indoor commercial environments. 316 neoksidebla ŝtalo provides superior protection against salt and moisture, perfect for coastal hotels or bars where humidity levels fluctuate.

Key selection points:

-

Indoor vs. humid environment: Choose 316 for higher moisture areas to prevent pitting and rust.

-

Cabinet location: Cabinets placed near dishwashers or beverage stations may encounter splashes, so corrosion resistance is critical.

-

Maintenance expectations: Higher-grade steel reduces long-term cleaning and polishing requirements.

In a five-star restaurant installation, Neoksidebla ŝtalo vinŝrankoj in 316 stainless resisted corrosion even after three years of heavy use, maintaining a sleek, scratch-free appearance.

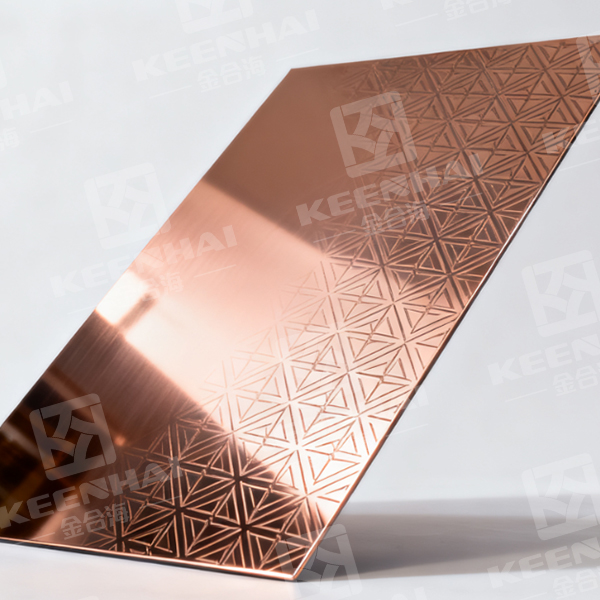

3.2 Surface Treatments: Polished, Brushed, PVD, or Matte

Surface finish influences both aesthetics and durability. Commercial wine cabinets can come with polurita, brosis, PVD, aŭ matte finishes. Each has its advantages:

-

Polished stainless steel: Reflective, elegant, ideal for display areas.

-

Brosita finpoluro: Hides fingerprints and minor scratches, low-maintenance.

-

PVD coating: Provides a durable colored layer, often gold, black, or bronze, enhancing premium appeal.

-

Matte: Modern, understated look, reduces glare in bright environments.

Comparison Table:

| Finish Type | Aspekto | Scratch Resistance | Prizorgado |

|---|---|---|---|

| Polished | Mirror-like | Moderate | Requires frequent cleaning |

| Brosita | Subtle texture | Alta | Low |

| PVD | Colored metallic | Tre Alta | Minimal, retains color |

| Mata | Flat, soft | Alta | Low |

A boutique wine bar integrated Neoksidebla Ŝtalo Vina Rack Kabineto units with PVD bronze finishes, giving the space a luxury, contemporary look while ensuring scratch resistance from frequent bottle handling.

3.3 Durability and Maintenance Considerations

Durability is a primary factor when selecting a cabinet for commercial use. Stainless steel is inherently strong, but proper material selection, surface treatment, and construction methods determine lifespan.

Operational tips to maintain durability:

-

Clean regularly: Use non-abrasive cleaners to avoid scratches.

-

Inspect joints and welds: Ensure structural integrity over time.

-

Avoid excessive moisture: Even high-grade steel benefits from controlled humidity.

-

Rotate bottles carefully: Reduces wear on shelves and racks.

In high-traffic commercial environments, investing in premium finishes and higher-grade steel can reduce maintenance costs and prolong the cabinet’s visual and functional quality. For example, a coastal hotel implemented brushed 316 stainless cabinets in their wine cellar, and after two years of heavy use, they still looked new with minimal upkeep.

4. Cooling, Humidity, and Environmental Control

4.1 Temperature Zones for Red, White, and Sparkling Wines

Maintaining precise temperature control is essential for commercial wine cabinets to preserve wine quality. Many high-end commercial setups use multi-zone cooling systems, which allow different wine types to be stored at optimal conditions simultaneously.

Typical temperature ranges:

-

Red wines: 12–18°C (54–65°F)

-

White wines: 7–12°C (45–54°F)

-

Sparkling wines: 5–8°C (41–46°F)

For example, a luxury hotel wine bar installed a three-zone cabinet with digital thermostats, enabling staff to serve reds, whites, and sparkling wines immediately without compromising flavor. Step-by-step setup includes:

-

Define the total number of bottles per zone.

-

Assign temperature requirements based on wine type.

-

Adjust digital thermostats and verify cooling uniformity across shelves.

Proper zoning ensures wine maintains its intended aroma, taste, and longevity, particularly for high-value bottles.

4.2 Humidity Control and Airflow Management

Humidity management is as critical as temperature. Ideal humidity levels prevent corks from drying out and minimize oxidation. Optimal humidity for most wines ranges between 50–70%. Commercial wine cabinets often integrate:

-

Humidifiers or water trays to maintain moisture

-

Vented shelving for airflow circulation

-

Sealed cabinet doors to prevent external air interference

Airflow considerations:

-

Ensure cold air circulates evenly across all racks.

-

Avoid direct air streams that can disturb sediment in wines.

-

Use fans strategically to maintain consistent conditions throughout the cabinet.

In a boutique wine shop, a custom multi-level cabinet used built-in airflow vents to ensure even temperature and humidity, keeping all wine racks at precise conditions, enhancing both storage safety and presentation.

4.3 Energy Efficiency and Operational Costs

Energy consumption directly affects long-term operational costs. Commercial stainless steel wine cabinets with advanced cooling technology often feature variable-speed compressors, LED lighting, and insulated cabinet walls, which reduce energy usage while maintaining precise environmental control.

Operational tips to optimize efficiency:

| Karakterizaĵo | Energy Benefit | Notes |

|---|---|---|

| Variable-speed compressor | Reduces electricity spikes | Adjusts cooling output based on load |

| LED-lumigo | Minimal heat generation | Extends life of internal lighting |

| Insulated doors and panels | Maintains temperature | Reduces compressor workload |

| Smart controllers | Optimize temperature zones | Automatic adjustments reduce human error |

A resort wine cellar retrofitted cabinets with LED lighting and insulated doors, cutting electricity consumption by 25% annually while keeping red, white, and sparkling wines within their ideal storage ranges. Routine maintenance—like cleaning condenser coils and verifying thermostat calibration—also improves efficiency and reduces unexpected downtime.

5. Supplier Selection and Purchasing Process

5.1 Evaluating Manufacturers and Commercial Suppliers

Choosing the right supplier is critical for ensuring consistent quality and timely delivery of commercial stainless steel wine cabinets. Start by evaluating:

-

Production capabilities: Verify that the supplier can handle both standard and custom configurations.

-

Certifications and quality standards: Look for ISO compliance and documented quality control procedures.

-

Previous projects: Request references or case studies of hotels, bars, or restaurants they have supplied.

A reliable supplier will also provide Commercial Wine Cabinet Stainless Steel solutions suitable for diverse environments, from hotel lobbies to high-volume restaurant storage, ensuring that cabinets meet both aesthetic and operational demands.

5.2 Lead Times, MOQ, and Bulk Order Capabilities

Understanding lead times and minimum order quantities (MOQ) is essential for planning large-scale installations. Typical steps include:

-

Confirm the supplier’s production capacity and typical turnaround for standard vs. custom cabinets.

-

Evaluate MOQ requirements—some manufacturers allow smaller initial orders for evaluation, while bulk orders usually reduce per-unit costs.

-

Compare delivery times and the supplier’s ability to scale production during peak seasons.

A luxury hotel chain ordered 50 multi-zone wine cabinets with custom PVD finishes. Coordinating with the supplier, they optimized the order into two batches to meet phased installation schedules without delaying restaurant openings.

5.3 Logistics, Shipping, and Installation Support

Efficient logistics and installation support can prevent costly delays and damage during transit. Key factors include:

-

Packaging standards: Commercial wine cabinets should be shipped with reinforced corners, foam padding, and moisture-resistant wraps.

-

Shipping methods: Air freight for urgent orders, sea freight for large bulk deliveries, depending on destination.

-

On-site installation: Suppliers offering professional installation or clear technical guidance reduce risk and ensure correct setup.

Some top-tier suppliers, including PVD Stainless Steel, provide turnkey solutions—handling both shipping logistics and in-field installation, ensuring cabinets are operational immediately upon arrival. This level of service is particularly valuable for large-scale commercial projects where precision and timing are critical.