The best coating for stainless steel depends on the application and environment. If you need maximum durability and scratch resistance for high-traffic areas, PVD or ceramic coatings are ideal because they fuse with the steel and can last 10–20 years or more. For decorative purposes, electroplating offers bright finishes like chrome, nickel, or gold at a lower cost, while powder coating provides versatile colors and strong corrosion protection for outdoor furniture or industrial panels. Choosing the right coating balances cost, durability, and aesthetics.

1. PVD Coatings (Physical Vapor Deposition)

1.1 Definition and Mechanism

PVD, or Physical Vapor Deposition, is a vacuum-based coating method that applies an ultra-thin layer of metal or metal compound onto stainless steel. Unlike traditional plating or painting, this process deposits material atom by atom, creating a coating that fuses with the steel surface rather than just sitting on top. The result is a layer that is harder, more durable, and able to resist scratches, corrosion, and fading.

The process typically involves placing the stainless steel in a sealed vacuum chamber, then vaporizing metals like titanium, zirconium, or chromium. Reactive gases may be added to form nitrides or carbides, producing various color finishes such as gold, bronze, or black. This technique is widely used in high-end architectural applications. For example, stainless steel elevator doors often use PVD coatings because they combine both durability and aesthetic appeal in high-traffic environments.

1.2 Advantages: Hardness, Scratch Resistance, and Color Options

One of the biggest reasons PVD is favored is its hardness. Standard stainless steel has a hardness around 150–200 HV, while PVD coatings can reach 1,500–2,500 HV, depending on the coating material. This makes surfaces highly resistant to scratches from daily contact, cleaning, or even accidental impacts.

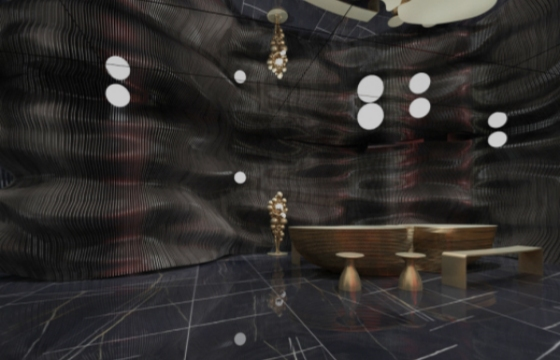

Besides toughness, PVD provides a wide range of color options without using paint. Titanium nitride produces gold, zirconium nitride produces bronze, and chromium-based coatings create silver or graphite tones. These finishes remain stable under UV light and resist fading, making them perfect for visible surfaces like elevator entrances, handrails, or decorative wall panels. A real-life application can be seen in commercial hotels and office towers that install stainless steel elevator entrances to combine long-lasting performance with a premium look.

1.3 Suitable Applications: Elevators, Interior Panels, Architectural Surfaces

PVD-coated stainless steel excels in both indoor and outdoor environments. Indoor applications include elevator doors, handrails, decorative panels, and furniture accents. Outdoor projects can involve façade panels, signage, or architectural cladding in commercial buildings.

For instance, a high-rise hotel in Singapore used PVD-coated bronze panels for its main lobby and elevator doors. After four years of heavy foot traffic, the surfaces showed no visible wear, fingerprints, or discoloration. Similarly, retail chains in Dubai use PVD-coated stainless steel for wall cladding in malls, combining durability with a luxurious finish.

This coating method is also eco-friendly because it avoids the toxic chemicals often used in electroplating. For those looking for premium, long-lasting stainless steel solutions, PVD coatings provide the right combination of strength, aesthetics, and low maintenance. Check more options at PVD stainless steel products for commercial or residential applications.

2. Electroplating Coatings

2.1 Common Types: Nickel, Chrome, Gold

Electroplating is a process where a thin layer of metal is deposited onto stainless steel using an electric current. The most common metals used are nickel, chrome, and gold, each offering distinct characteristics.

-

Nickel plating provides corrosion resistance and a slightly warm silver finish. It’s often used for elevator buttons, handrails, and decorative trims.

-

Chrome plating produces a bright, reflective surface that resists tarnishing, making it popular for faucets, handles, and modern furniture hardware.

-

Gold plating is chosen for its luxury appeal, often found in upscale interior fixtures, designer hardware, and high-end elevator buttons.

A practical example comes from a boutique hotel in London. The elevator interiors used chrome-plated stainless steel panels and nickel-plated control buttons. The reflective chrome panels created a spacious feel, while the nickel buttons reduced fingerprints and wear.

2.2 Strengths and Weaknesses

Electroplating has several advantages but also some limitations compared to other coatings like PVD.

-

Strengths:

-

Visually striking finishes, including mirror-like reflections or golden tones.

-

Moderate corrosion resistance when proper undercoating is used.

-

Relatively low initial cost for small-scale applications.

-

-

Weaknesses:

-

Surface hardness is generally lower than PVD coatings. For example, chrome plating usually achieves 400–600 HV, while PVD can reach 1,500–2,500 HV.

-

Susceptible to peeling or flaking over time if the underlying surface is not perfectly prepared.

-

Some processes involve toxic chemicals, making waste disposal a concern.

-

Here’s a simplified comparison table for quick reference:

| Coating Type | Hardness (HV) | Corrosie Resistance | Color Options | Typical Use |

|---|---|---|---|---|

| Nickel | 300–500 | Medium | Silver/Warm | Buttons, trims |

| Chrome | 400–600 | Medium-High | Bright Silver | Faucets, handles |

| Gold | 150–250 | Low-Medium | Gold | Luxury hardware |

2.3 Ideal Use Cases: Decorative Hardware, Fixtures, Handles

Electroplated stainless steel is ideal for applications where aesthetics are a priority and the surface doesn’t face extreme wear. Common uses include:

-

Decorative hardware – Door handles, cabinet pulls, and trim pieces in hotels or luxury apartments.

-

Fixtures – Elevator buttons, wall-mounted switches, and restroom hardware. A notable project is a residential tower in Paris where residential elevator doors were paired with nickel-plated control panels to match interior décor.

-

Handles – Kitchen and bathroom fixtures, especially when designers want a bright, reflective finish.

Electroplating allows designers to match finishes across different components, ensuring a consistent look. However, it’s important to remember that in high-traffic areas, PVD-coated surfaces may outperform electroplated ones in durability.

3. Powder Coatings

3.1 Process Overview and Material Types

Powder coating is a dry finishing process where powdered paint or polymer is applied electrostatically to stainless steel and then baked in an oven. Unlike liquid paints, powder coating forms a uniform, hard layer that bonds with the surface. The process generally involves:

-

Surface cleaning and preparation – Stainless steel parts are degreased and sometimes lightly sandblasted to remove imperfections.

-

Powder application – A fine powder, usually polyester, epoxy, or polyurethane, is sprayed onto the surface using an electrostatic gun. The charged powder sticks evenly to the steel.

-

Curing – The coated piece is baked at high temperatures (typically 180–200°C) for 10–20 minutes, allowing the powder to melt and form a smooth, durable finish.

Powder coating offers a wide variety of color and texture options, from matte black to metallic bronze. For example, stainless steel panels for commercial kitchens often use epoxy powders for heat resistance, while outdoor furniture may use polyester powders for UV stability.

3.2 Durability and Corrosion Protection

Powder coating provides strong corrosion resistance and durability compared to conventional paint. The baked-on finish protects stainless steel from moisture, chemicals, and minor abrasions.

Studies show that powder-coated stainless steel can resist salt spray corrosion for over 1,000 hours, making it suitable for coastal or outdoor environments. It also withstands daily wear, cleaning, and moderate impact without chipping.

Here’s a comparison with other common coatings:

| Coating Type | Corrosie Resistance | Scratch Resistance | Typical Thickness | Suitable Use |

|---|---|---|---|---|

| Powder Coating | Heech | Medium-High | 50–100 microns | Outdoor furniture, industrial panels |

| Liquid Paint | Medium | Medium | 30–50 microns | Indoor furniture, decorative panels |

| PVD Coating | Very High | Very High | 2–5 microns | Premium surfaces, high-traffic areas |

Powder coatings are particularly advantageous for large panels or irregular shapes, where achieving an even liquid paint finish would be difficult.

3.3 Best Applications: Outdoor Furniture, Industrial Equipment

Powder-coated stainless steel shines in applications that require both aesthetic appeal and protection from harsh conditions. Common uses include:

-

Outdoor furniture – Chairs, tables, benches, and railings that face sun, rain, and humidity. Polyester powders are preferred for UV resistance.

-

Industrial equipment – Machine guards, electrical enclosures, and storage units that need chemical and scratch resistance.

-

Architectural panels and cladding – Large wall panels in commercial buildings or stadiums benefit from the even coverage and color options powder coating offers.

A practical example is a seaside restaurant in Spain that installed powder-coated stainless steel railings and outdoor tables. After three years of constant exposure to sun, rain, and salt air, the surfaces remained intact, with minimal color fading or rust. Powder coating provides a cost-effective solution for large-scale projects that require both beauty and durability, making it ideal for stainless steel applications beyond just elevators.

4. Ceramic Coatings

4.1 Coating Process and Properties

Ceramic coatings on stainless steel involve applying a thin layer of ceramic material, typically using a thermal spray or sol-gel process, to create a hard, protective surface. The process usually follows these steps:

-

Surface preparation – Stainless steel surfaces are cleaned, degreased, and sometimes sandblasted to improve adhesion.

-

Ceramic application – Ceramic powder or suspension is sprayed or dipped onto the steel. Thermal spraying melts the particles, which then fuse onto the metal.

-

Curing or sintering – The coated piece is heated to form a dense, uniform layer that bonds tightly to the stainless steel substrate.

Ceramic coatings are extremely thin—usually 20–100 microns—but they dramatically increase hardness and wear resistance. Depending on the ceramic composition, coatings can produce finishes ranging from matte gray to metallic shades. They also maintain color stability under extreme heat, making them ideal for industrial and architectural applications. For high-end solutions, you can combine ceramic coatings with PVD stainless steel products to achieve both durability and aesthetic appeal.

4.2 Heat and Wear Resistance

One of the main advantages of ceramic coatings is their ability to withstand high temperatures and abrasive conditions. Hardness levels can exceed 2,500 HV, comparable to or even higher than PVD coatings, and some ceramics resist heat up to 800–1,200°C without breaking down.

This makes them perfect for environments where stainless steel is exposed to friction, heat, or mechanical wear. For example, industrial kitchen equipment, exhaust panels, and high-friction handles in factories often use ceramic-coated stainless steel to prevent scratches, dents, or discoloration over time. Compared to powder coatings or electroplating, ceramic layers maintain performance under conditions that would cause other coatings to fade or chip.

4.3 Recommended Environments: High-Temperature or Abrasive Surfaces

Ceramic-coated stainless steel is best for situations where extreme durability is required:

-

Industrial machinery and equipment – Conveyor parts, machine guards, or structural panels exposed to heat and abrasion.

-

High-traffic architectural elements – Stairs, handrails, or wall panels in public areas that endure constant contact or wear.

-

Specialty applications – Laboratory surfaces, commercial kitchen panels, and even high-end elevator interiors, where resistance to scratches, heat, and chemical contact is essential.

For instance, a commercial kitchen in Germany installed ceramic-coated stainless steel countertops and ventilation panels. Even after years of constant exposure to heat, acidic cleaning agents, and heavy usage, the surfaces showed virtually no wear or corrosion. Using ceramic coatings ensures long-lasting performance while maintaining a sleek, professional appearance.

5. Comparison of Coating Types

5.1 Hardness, Corrosion, and Wear Resistance Table

When deciding which coating is best for stainless steel, it’s useful to compare their performance metrics side by side. Hardness, corrosion resistance, and wear resistance are key factors for durability and maintenance. The table below summarizes the main coatings we’ve discussed:

| Coating Type | Hardness (HV) | Corrosie Resistance | Wear Resistance | Typical Use Cases |

|---|---|---|---|---|

| PVD Coating | 1,500–2,500 | Very High | Very High | Elevator doors, premium architectural panels |

| Electroplating | 150–600 | Medium | Medium | Decorative hardware, handles, trims |

| Powder Coating | 300–600 | Heech | Medium-High | Outdoor furniture, industrial panels |

| Ceramic Coating | 2,500+ | Very High | Very High | Industrial machinery, high-traffic surfaces |

This table shows that PVD and ceramic coatings excel in both hardness and wear resistance, making them ideal for high-traffic or high-impact environments. Powder coatings offer a balance of corrosion resistance and color versatility, while electroplating remains a cost-effective option for decorative elements.

5.2 Cost Considerations

Cost is often a deciding factor when selecting a coating. Here’s a rough comparison:

-

Electroplating – Lowest cost, ideal for small-scale decorative applications. It can start as low as $10–$20 per square foot depending on the metal used.

-

Powder Coating – Moderate cost, roughly $15–$30 per square foot, offering long-lasting color and corrosion protection for outdoor or industrial projects.

-

PVD Coating – Premium pricing, $50–$100 per square foot, justified by exceptional hardness, aesthetics, and long-term durability. Suitable for high-end projects like commercial elevator doors or architectural panels.

-

Ceramic Coating – High cost, similar to PVD, around $60–$120 per square foot, mainly used in industrial or extreme environments where performance outweighs initial cost.

For instance, a luxury hotel in Hong Kong chose PVD-coated stainless steel for elevator doors despite the higher upfront cost because it reduced maintenance and replacement expenses over time.

5.3 Longevity and Maintenance Requirements

The expected lifespan and maintenance frequency vary significantly between coatings:

-

PVD Coating – Can last 10–20 years with minimal cleaning using a soft cloth and mild detergent. Fingerprints and scratches are rare, making it ideal for high-traffic areas.

-

Electroplating – Typically lasts 3–7 years indoors, but outdoor or high-touch areas may require frequent touch-ups or polishing to prevent peeling or tarnishing.

-

Powder Coating – Usually lasts 7–15 years outdoors depending on UV exposure and environmental conditions. Cleaning is simple, but harsh abrasives may damage the finish.

-

Ceramic Coating – Extremely durable, 15–25 years, even in industrial or high-heat environments. Requires very little maintenance beyond routine dusting and occasional washing.

A real-world example: industrial kitchens in Germany use ceramic-coated stainless steel panels, which remain intact and visually appealing after a decade of heavy heat, chemical exposure, and scrubbing, outperforming powder-coated alternatives.

If you want the longest-lasting color and lowest maintenance, read our deep dive: What is a PVD stainless steel sheet?