The main pros of Material Inox lie in its long-term reliability, low maintenance, and strength-to-thickness ratio, while its cons include heavier weight than aluminum, higher fabrication costs, and visible fingerprints on polished surfaces; evaluating these factors in the context of specific environmental conditions, load requirements, and aesthetic goals helps architects and engineers make informed decisions and maximize both durability and cost-effectiveness.

1. Key Advantages of Material Inox

Material Inox stands out in projects where moisture, pollution, or constant human contact quickly break down ordinary metals. Architects use it for exterior façades, subway interiors, commercial kitchens, and high-traffic public spaces because it holds its appearance and mechanical integrity even under aggressive conditions. When a project demands a metal panel that won’t stain, peel, or weaken after years of exposure, Material Inox consistently outperforms alternative alloys.

1.1 Corrosion and Oxidation Resistance

The strongest advantage of Material Inox is its corrosion resistance. The chromium-rich surface forms a thin, stable protective layer that repairs itself whenever oxygen is present. That’s why a Lamiera in acciaio inossidabile used on a seaside balcony or a coastal restaurant façade doesn’t pit or rust the way untreated carbon steel does.

You can see the difference clearly in humid cities like Miami or Hong Kong. Metal handrails made with Inox stay clean and smooth, while cheaper alloys show orange stains within months. This performance is not theoretical; contractors choose Inox precisely because clients expect a surface that stays “new-looking” without constant refinishing.

To illustrate how the resistance levels compare, here is a simple parameter table:

| Tipo di materiale | Exposure to Salt Air | Expected Service Life | Surface Degradation |

|---|---|---|---|

| Materiale Inox | Excellent | 25–40+ years | Minimal |

| Painted Carbon Steel | Poor | 5–10 years | Coating cracks, rust develops |

| Galvanized Steel | Moderate | 10–20 years | Zinc layer wears down |

1.2 High Structural Strength and Durability

Material Inox brings a structural strength level that works well in both thin sheet profiles and thick load-bearing plates. Engineers choose it when they need metal panels that don’t flex, dent, or deform under daily contact. In large public buildings—train stations, shopping malls, airports—workers install Inox cladding because the surface stays rigid even when thousands of people touch or lean against it every day.

When projects require thicker components, such as stair brackets or outdoor framing connectors, contractors often move to a heavier section like an SS Steel Plate, especially when they want stronger impact resistance.

This strength advantage becomes noticeable during installation. A typical 2 mm Inox panel can remain flat without oil-canning, while other materials need additional framing or stiffeners to avoid visible warping. Less structural reinforcement means faster installation and lower project costs.

1.3 Low Maintenance and Easy Cleaning

Material Inox reduces maintenance frequency because grease, dust, and fingerprints don’t chemically bond to it the way they do on painted metal. A single wipe with a microfiber cloth usually restores the finish. That’s why hospitals, food-grade factories, and high-end restaurants use Inox panels around their work surfaces—cleaning teams can move quickly without using aggressive chemicals.

Cleaning steps typically follow a simple routine:

-

Wet the surface with warm water to loosen debris.

-

Wipe along the metal grain using a soft cloth.

-

Apply a mild detergent only if needed.

-

Rinse and dry thoroughly to keep the finish crisp.

Because the surface tolerates repeated cleaning without fading, contractors rarely need to repaint or recoat it. This is especially useful on elevator interiors, ticket kiosks, and commercial signage where daily cleaning is unavoidable.

1.4 Aesthetic Versatility for Modern Designs

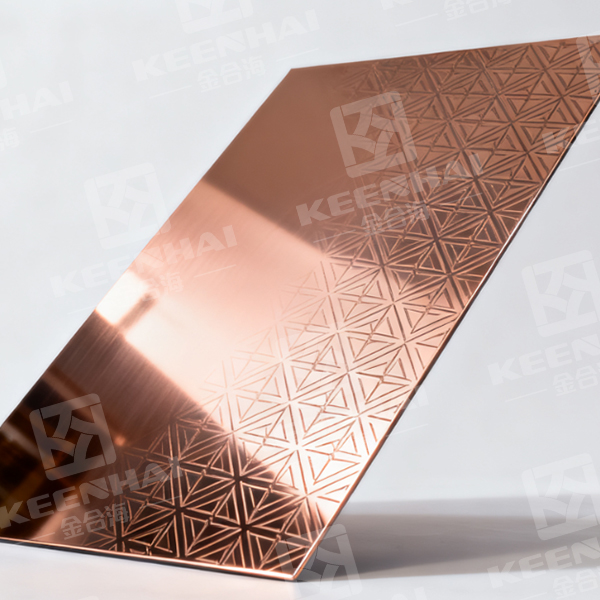

Designers choose Material Inox for its ability to shift between minimalistic and high-luxury aesthetics. It works in brushed, mirrored, bead-blasted, embossed, and colored PVD finishes, giving architects the freedom to match exterior façades with interior details. In modern hotels, developers combine satin Inox wall panels with mirrored ceiling strips to brighten narrow corridors, while retail brands use dark PVD tones to create a premium, high-contrast storefront.

When a design calls for thicker panels—for example, custom signage plates or heavy exterior trims—fabricators may switch to a Piastra metallica in acciaio inossidabile to achieve sharper edges and deeper grooves.

Material Inox also maintains its appearance under strong lighting, which makes it ideal for architectural projects that rely on reflections, such as luxury mall façades or public art installations. The surface stays crisp even under sunlight, stage lights, or LED wall washers, giving designers predictable and long-lasting visual effects.

2. Practical Disadvantages of Material Inox

2.1 Higher Initial Material and Processing Costs

While material inox delivers excellent durability, its upfront cost is higher than many conventional metals. The alloying elements—especially nickel and molybdenum—raise the raw material price, and the fabrication process often requires specialized cutting or welding equipment. For projects with budget constraints or large-surface applications, this cost difference can become a major consideration.

2.2 Weight Limitations in Certain Applications

Although material inox offers impressive mechanical strength, it can be heavier than aluminum or composite alternatives. This added weight affects applications that require reduced structural load, such as large façade panels, suspended ceilings, or lightweight architectural components. When weight efficiency is a priority, designers may need to evaluate whether stainless steel is the most suitable option.

2.3 Fingerprints, Smudges, and Surface Marks Issues

Polished or brushed material inox surfaces tend to show fingerprints and smudges more easily, especially in high-touch areas like doors, elevator panels, and handrails. While these marks do not affect performance, they require more frequent cleaning to maintain a pristine appearance. In environments that demand a consistently clean look, maintenance planning becomes an important part of material selection.

2.4 Limited Workability Compared to Softer Metals

Materiale inox is significantly harder and less malleable than softer metals, making it more challenging to cut, bend, or form into complex shapes. The machining process can generate more tool wear and may require slower feed rates or specialized tooling. For designs that involve intricate curves or deep forming, stainless steel can introduce additional time and cost due to its limited workability.

3. Performance Factors That Influence Pros & Cons

3.1 Inox Grade Variations (304 vs 316 vs 430)

Different grades of material inox deliver very different real-world results, so the advantages and drawbacks depend heavily on the chosen alloy. Grade 304 offers balanced corrosion resistance and affordability, which makes it suitable for indoor architectural panels, kitchen equipment, and general construction. Grade 316 increases durability with 2–3% molybdenum, and this composition improves chloride resistance by over 30–40% compared with 304, so coastal environments and industrial zones rely on 316 for long-term performance. Grade 430, which contains minimal nickel, works well in interior applications where corrosion exposure stays low, but it cannot handle high moisture or chemical contact.

When selecting a grade, designers usually follow three steps:

-

Compare expected humidity, chemical exposure, and temperature cycles.

-

Match these conditions with corrosion-resistance benchmarks from manufacturer test data.

-

Confirm fabrication requirements—thickness, forming radius, weld points—to ensure the chosen grade meets engineering tolerances.

Because each alloy responds differently to stress, heat, and abrasion, grade selection directly influences the pros and cons of the final system.

3.2 Surface Finish and Coating Impact

The surface treatment of material inox changes both its durability and its handling characteristics. A highly polished No.8 finish delivers strong reflectivity and reduces dirt retention by 15–25%, but it highlights fingerprints in commercial interiors. A brushed No.4 finish hides scratches and smudges more effectively, which makes it suitable for elevators, wall panels, and high-traffic zones. Designers often apply nano-coatings or anti-fingerprint (AFP) layers to cut cleaning frequency and extend the shine of decorative installations.

Surface properties also influence fabrication. A rougher finish increases friction during forming, so workshops often reduce feed speed by 10–20% to prevent micro-tears along bends. When projects involve deep drawing or tight curves, engineers typically choose smoother finishes to maintain structural integrity.

Because finish quality affects appearance, maintenance, and machining efficiency, the performance of inox systems depends as much on the finish as on the grade itself.

3.3 Environmental Conditions and Exposure Levels

Environmental exposure determines how material inox performs over long service periods. Coastal regions with airborne salts speed up surface staining, so installers usually recommend 316 or coated variants to maintain stability. Industrial environments with sulfur compounds or high-temperature exhaust create localized corrosion, and designers must map airflow, proximity to emission points, and thermal cycles before specifying thickness or grade.

To maintain long-term performance, most projects follow these steps during installation and operation:

-

Clean the surface with non-chloride solutions before installation to remove contaminants that accelerate corrosion.

-

Maintain a consistent inspection interval—usually every 6–12 months for façades or equipment in harsh climates—to detect discoloration or early pitting.

-

Apply protective sealants in environments with variable pH conditions to stabilize the surface film.

Environmental stress directly changes the balance between advantages such as longevity and disadvantages such as cleaning frequency, so the surrounding conditions strongly shape the real pros and cons of inox materials.

4. When Material Inox Is the Best Choice

4.1 High-Humidity or Salt-Rich Environments

Material inox performs exceptionally well in demanding coastal or moisture-heavy zones because its chromium-rich surface film rebuilds itself whenever oxygen touches the metal. This self-healing layer gives inox a reliability that aluminum or painted steel rarely match in salt-laden air. In seaside buildings, designers often specify 316-grade components for canopies, handrails, façade trims, and exposed fasteners because they stay stable even after constant spray cycles. In swimming pool halls, the humidity, chlorine, and temperature shifts push many metals to fail early, but inox maintains its integrity and appearance without warping or flaking.

Real-world projects like beachfront boardwalks or resort balconies usually rely on inox because it cuts long-term replacement cycles and keeps structural parts looking consistent even after years of UV exposure, salt fog, and daily condensation.

4.2 Projects Requiring Long-Term Wear Resistance

Inox stands out when a structure needs to absorb constant friction, impact, or repetitive movement. Its tensile strength and abrasion resistance help designers avoid deformation in areas where softer metals wear out quickly. Public transit hubs use inox for escalator panels, elevator interiors, ticketing counters, and column cladding because tens of thousands of daily touches barely change the surface.

In industrial workshops, operators rely on inox for machine guards, heavy-use benches, and protective railings since the alloy handles tool strikes, vibration, and rolling carts without denting. The metal’s density and hardness keep it stable under continuous contact, and this long-term consistency reduces lifecycle costs in environments where repairs are disruptive.

4.3 Applications Demanding Hygiene and Cleanability

Material inox works extremely well in kitchens, laboratories, food-processing areas, and healthcare spaces because its non-porous surface blocks bacteria and chemical absorption. When a smooth finish meets correct cleaning procedures, inox maintains strict hygiene standards even under aggressive sanitation cycles.

To keep surfaces sterile and visually uniform, most facilities follow a simple operation flow:

-

Rinse the inox surface with warm water to remove loose particles.

-

Apply a neutral detergent with a microfiber cloth and scrub along the grain direction to avoid swirl marks.

-

Rinse again and dry completely to prevent mineral spots and preserve the protective film.

Commercial kitchens prefer inox for counters, splashbacks, storage racks, and high-heat zones because it handles oils, acids, temperature spikes, and daily scrubbing without losing structural or aesthetic performance. In medical or biotech labs, the material’s resistance to disinfectants gives technicians confidence during repeated sterilization cycles.