When comparing Inox Steel and Stainless Steel Sheet, the key is balancing initial cost, long-term durability, and environmental performance: inox steel offers a lower upfront price and works well for indoor or low-exposure projects, while stainless steel, especially grades like 316, provides superior corrosion resistance, mechanical strength, and lifespan for outdoor, high-humidity, or industrial applications, making it a smarter choice for projects where maintenance and replacement costs are critical over time.

1. Key Material Differences That Affect Cost

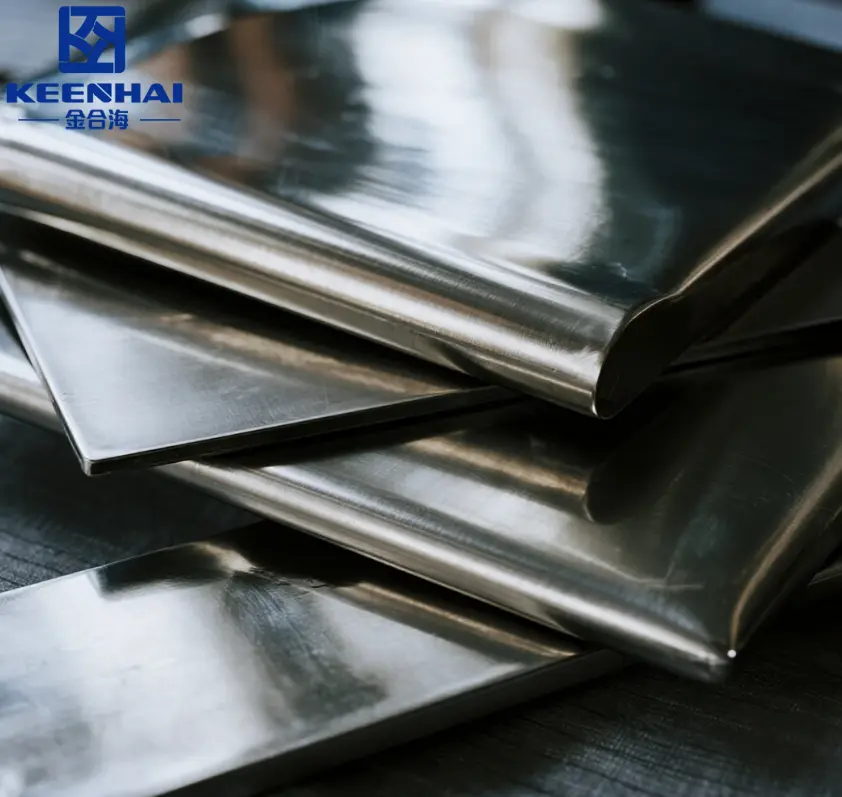

When comparing inox steel and stainless steel, the first cost differences come directly from the materials themselves. In practical applications like outdoor stair railings, kitchen countertops, or architectural panels, even minor changes in alloy or thickness can have a noticeable impact. The main drivers are chemical composition, processing complexity, and raw material market behavior, which together determine the price before installation begins.

1.1 Chemical Composition and Alloy Content

Steel alloys vary significantly in chromium, nickel, and molybdenum content, which directly influences corrosion resistance and price. For example, a standard stainless steel sheet with more nickel performs much better in humid environments but costs more upfront. For architectural projects, I often check whether the required stainless steel sheet meets environmental and aesthetic needs before finalizing specifications.

Here’s a clear comparison to illustrate how alloy content affects cost and application:

| Materiāla veids | Alloy Content | Cost Level | Typical Use |

|---|---|---|---|

| Carbon Steel | Low alloy, mostly iron | Low | Support frames, sheds |

| Stainless Steel 304 | Chromium + Nickel | Vidēja | Indoor kitchens, trims |

| Stainless Steel 316 | Chromium + Nickel + Molybdenum | High | Coastal façades, outdoor staircases, high-humidity zones |

This table highlights why two sheets with identical thickness can have vastly different prices: the added alloy improves performance and reduces long-term maintenance, especially in outdoor or high-moisture environments.

1.2 Manufacturing Complexity and Processing Cost

Processing can add significant cost. A sheet intended for high-finish panels or kitchen surfaces goes through multiple steps to achieve flatness, surface quality, and precision:

-

Controlled hot rolling for structural stability.

-

Multiple cold-rolling passes to reach exact thickness.

-

Tension leveling to reduce warping.

-

Surface finishing such as No.4 brushed, mirror polish, or PVD coating.

-

Cut-to-size trimming to fit exact installation drawings.

Each step consumes time, labor, and materials. In real-world projects like boutique hotel façades or restaurant kitchens, the finishing stage alone can contribute 25–35% of total panel cost. Choosing pre-finished panels minimizes on-site labor and ensures consistency in visible areas.

1.3 Market Availability and Raw Material Price Fluctuations

Material supply and price volatility strongly affect cost. Nickel and molybdenum prices fluctuate frequently, impacting 304 and 316 stainless steel grades. Large surface projects—such as mall corridors, outdoor staircases, or decorative wall panels—are especially sensitive because mills prioritize standard thicknesses first.

Practical considerations include:

-

Limited stock for uncommon sizes increases cost and delivery time.

-

Common thicknesses like 1.0–1.5 mm are easier to source, while 2–3 mm specialty panels may take weeks longer.

-

Early confirmation of stock avoids schedule delays and unexpected price increases.

In real-world construction, these factors often make material lead time and availability as important as base price when estimating total project cost.

2. Price Comparison in 2025

Understanding the cost differences between inox steel and stainless steel in 2025 is critical for budgeting both small and large projects. Market trends, grade selection, and project scale all directly influence the per kilogram price, which in turn affects total construction or fabrication costs. Designers and procurement teams must factor in these elements to avoid surprises, especially for high-visibility architectural elements or industrial equipment.

2.1 Average Cost per kg (Global Market Data)

In 2025, the global price for nerūsējošais tērauds ranges widely depending on grade, thickness, and regional market factors. On average:

-

304 stainless steel costs around $2.50–$3.20 per kg.

-

316 nerūsējošais tērauds is priced higher at $3.50–$4.20 per kg due to added molybdenum for corrosion resistance.

-

201 stainless steel is the most economical at $1.80–$2.20 per kg.

These averages reflect the cost from major suppliers in Asia, Europe, and North America. For example, sourcing SS steel plate for a coastal hotel project might fall at the upper end of the 316 range, because corrosion resistance is a must in high-humidity zones.

Practical tip: Locking in stock early can save up to 10% per ton compared to spot market prices during volatile months.

2.2 Price Differences Across Grades (304, 316, 201, etc.)

Grade selection directly impacts cost efficiency. 304 and 316 grades dominate architectural and industrial applications due to their durability, while 201 is mainly used for budget-sensitive projects.

| Stainless Steel Grade | Alloy Content | Typical Price per kg (2025) | Ieteicamais lietojums |

|---|---|---|---|

| 201 | Lower Ni, Cr | $1.80–$2.20 | Indoor panels, furniture trims |

| 304 | Moderate Ni, Cr | $2.50–$3.20 | Kitchens, handrails, indoor façades |

| 316 | High Ni, Cr + Mo | $3.50–$4.20 | Coastal façades, outdoor staircases, humid environments |

Even when the thickness is identical, 316 panels can cost up to 50% more than 304, but their long-term performance reduces maintenance, which is often more cost-effective for large installations.

2.3 Cost Impact for Large-Scale vs Small Projects

Project size amplifies cost differences in multiple ways:

-

Bulk purchasing discounts: Large-scale orders for hotel façades or mall staircases often secure 5–15% savings per kg.

-

Handling and storage: Small projects may incur higher per-unit transport and handling costs because suppliers prioritize bulk shipments.

-

Cutting and finishing: Large projects often allow centralized finishing, reducing labor per panel, while small projects may require local shops to perform cutting, increasing cost.

-

Waste factor: Smaller projects frequently waste more material percentage-wise due to trimming non-standard sizes.

For example, ordering stainless steel metal plate for a 50-panel outdoor canopy might be 10% cheaper per kg than sourcing 5 panels for a boutique kitchen counter, even if the grades are identical, because the supplier can optimize production and reduce waste.

Planning material specifications and early procurement can significantly reduce costs for both large and small projects.

3. Performance Comparison in Real Applications

In practical projects, inox steel and stainless steel perform differently depending on environmental exposure and mechanical demands. Architects, fabricators, and engineers often select materials based on corrosion behavior, strength, and chemical stability rather than just initial cost. Outdoor stair railings, kitchen counters, and industrial equipment panels demonstrate how performance directly influences long-term value.

3.1 Corrosion Resistance and Environmental Performance

Stainless steel grades vary widely in corrosion resistance. 304 is suitable for indoor and moderately humid environments, while 316 withstands salty coastal air and high-humidity conditions. Materials with higher molybdenum and nickel content resist pitting and crevice corrosion better.

-

For example, a coastal hotel used stainless steel sheet for handrails and façade panels, which maintained its finish after three years of direct exposure to sea spray.

-

In industrial kitchens, panels must resist repeated cleaning with chemicals; 304 is often sufficient for walls and backsplashes, while 316 panels handle more aggressive cleaning agents.

Corrosion tests show that 316 stainless steel can resist chloride-induced pitting at concentrations up to 1000 ppm, while 304 may start corroding around 200–300 ppm, which is critical for outdoor and high-humidity installations.

3.2 Mechanical Strength, Hardness, and Wear Resistance

Mechanical performance affects both structural safety and maintenance requirements. Stainless steel sheets and SS steel plate differ in yield strength, tensile strength, and hardness:

| Materiāls | Yield Strength (MPa) | Tensile Strength (MPa) | Hardness (HRB) | Typical Use |

|---|---|---|---|---|

| 201 | 205–230 | 380–450 | 70–85 | Indoor panels, decorative trims |

| 304 | 215–275 | 505–700 | 80–95 | Kitchens, indoor stair railings |

| 316 | 215–290 | 515–720 | 85–100 | Outdoor staircases, industrial equipment |

Higher strength grades reduce deformation risk for load-bearing panels. For instance, outdoor pergolas or industrial frames fabricated from 316 maintain straightness under wind and mechanical stress, minimizing the need for mid-life replacements.

Wear resistance also matters for high-traffic surfaces like elevator interiors, countertops, or commercial kitchens, where repeated contact can dull or scratch lower-grade panels over time.

3.3 Heat Resistance and Chemical Durability

Some projects expose panels to elevated temperatures or aggressive chemicals, such as commercial kitchens, chemical plants, or exterior cladding near exhaust vents.

-

304 stainless steel resists temperatures up to around 870°C, suitable for most indoor applications.

-

316 nerūsējošais tērauds maintains structural integrity up to 925°C, which is critical near heat sources or high-temperature exhausts.

-

Surface treatments like passivation or PVD coatings further enhance chemical resistance, especially in acidic or saline environments.

Using metal stainless steel sheet with proper treatment prevents discoloration, warping, or pitting in these harsh conditions. For example, a seaside restaurant installed metal stainless steel sheet for exterior countertops, which held up to repeated cleaning and occasional acid spills over multiple years.

4. Long-Term Value: Cost Efficiency vs Performance

When evaluating stainless steel versus inox steel, the total cost isn’t just the purchase price—it’s the combination of maintenance, lifespan, repair needs, and overall performance in the intended environment. High-quality stainless steel panels often require less frequent intervention, which significantly improves the cost-to-performance balance over years of use.

4.1 Maintenance Needs and Expected Lifespan

Maintenance frequency varies by grade and application:

-

Routine cleaning: For indoor installations, wipe with mild detergent weekly to prevent minor stains.

-

Periodic inspection: Outdoor panels or high-traffic surfaces should be inspected every 6–12 months for corrosion or scratches.

-

Protective treatment: Applying a passivation layer or PVD coating extends lifespan in harsh environments.

304 stainless steel typically lasts 15–25 years in moderate conditions, whereas 316 can exceed 30 years in high-humidity or coastal locations. For large-scale projects, using nerūsējošais tērauds panels in staircases or façades reduces long-term labor and cleaning costs compared to lower-grade alternatives.

4.2 Repair, Replacement Cost, and Failure Risk

Material choice directly impacts unexpected repair or replacement costs:

-

Minor dents and scratches in 201 grade often require panel replacement or refinishing, which can be costly if parts are non-standard.

-

Corrosion-induced failure in low-grade stainless steel sheets accelerates replacement schedules, whereas 316 panels resist pitting for decades.

-

For large installations, the labor component often outweighs material cost, so choosing higher-grade stainless steel sheet reduces the likelihood of mid-life replacement.

Steps to minimize failure risk:

-

Select grade based on environmental exposure.

-

Ensure professional installation to prevent stress points.

-

Apply coatings or protective layers where chemical or saline exposure is expected.

4.3 Performance-to-Cost Ratio for Different Use Cases

Balancing performance and cost is about matching the grade to the application:

-

High-humidity or outdoor structures: 316 stainless steel panels justify higher upfront cost through long-term durability.

-

Indoor décor and kitchen counters: 304 panels provide excellent performance at a lower price point.

-

Small-scale vs large-scale projects: Bulk orders can improve the performance-to-cost ratio by reducing handling, transport, and labor per unit.

For example, an outdoor canopy using metal stainless steel sheet will cost more upfront but avoids replacement for 20+ years, whereas using lower-grade panels might require replacement every 5–7 years, increasing total cost significantly.

5. Choosing the Better Option for Your Budget

Selecting between inox steel and stainless steel is all about weighing upfront cost against long-term performance. The ideal choice depends on project size, environmental conditions, and expected lifespan. By carefully analyzing these factors, you can make a decision that maximizes value without overspending.

5.1 When Inox Steel Is the More Cost-Effective Choice

Inox steel often works well in indoor projects or low-corrosion environments. It provides sufficient durability for walls, trims, and decorative elements where exposure to moisture or chemicals is limited.

-

For example, office partitions or indoor staircase handrails often use inox steel because it offers a lower upfront cost while still maintaining acceptable appearance and strength over 10–15 years.

-

In small-scale residential projects, the savings on material can outweigh the slightly shorter lifespan compared to higher-grade stainless steel.

Steps to decide if inox is right:

-

Evaluate environmental exposure (humidity, salt air, chemicals).

-

Estimate project lifespan and maintenance tolerance.

-

Compare upfront costs versus long-term replacement probability.

5.2 When Stainless Steel Offers Better Long-Term Value

Stainless steel is ideal for high-humidity, coastal, or industrial environments where corrosion, wear, and chemical exposure are significant concerns.

-

For instance, kitchens, exterior façades, and industrial equipment panels benefit from nerūsējošais tērauds because its resistance to pitting and wear reduces maintenance and replacement frequency.

-

316 grade panels in outdoor installations may cost more initially but often last 20–30 years, lowering total lifecycle cost and avoiding downtime for repairs.

Higher upfront costs are justified when expected maintenance or replacement expenses for inox would exceed the price difference over time.

5.3 How to Match Material Choice to Project Requirements

Choosing the right material requires a systematic evaluation of both functional and financial factors:

-

Assess environmental exposure – high humidity, coastal air, or chemical contact favors higher-grade stainless steel.

-

Determine mechanical demands – load-bearing or high-wear areas need materials with higher tensile strength and hardness.

-

Estimate lifecycle cost – factor in initial cost, maintenance, repair, and potential replacement.

-

Select appropriate grade and finish – 304 is sufficient for indoor and moderate use, while 316 or PVD-coated sheets handle extreme conditions.

For large-scale or long-term projects, using stainless steel sheet for staircases, industrial panels, or outdoor installations ensures optimal performance-to-cost ratio, while smaller, low-exposure projects may achieve savings with inox steel without compromising durability.