The price of Material Inox in 2025 varies depending on the grade and form. For instance, 304 Stainless Steel Sheet ranges from $2,700–$2,900 per ton, while 316-grade panels are $3,200–$3,350 per ton due to higher nickel and molybdenum content. Coils, bars, and tubes follow similar pricing patterns influenced by production complexity and thickness. Regional differences also matter, with Southeast Asia generally offering lower rates compared to Europe or North America. Project planners can reduce costs by ordering in bulk, choosing the right alloy, and timing purchases according to market trends.

1. Factors Influencing Inox Material Cost

The cost of Инокс материјал in 2025 is shaped by a combination of raw material trends, processing complexities, regional differences, and market demand. Understanding these factors helps manufacturers, contractors, and buyers plan budgets effectively for construction, industrial applications, or custom projects.

1.1 Raw Material Prices

The primary driver of Inox cost is the price of raw metals such as nickel, chromium, and iron. Nickel prices alone can swing Inox material costs by 10-20% over a few months depending on global supply. For example, a high-end Лим од не'рѓосувачки челик used in modern kitchen facades can cost significantly more if nickel surges. Additionally, scrap metal recycling rates also influence pricing—high scrap availability tends to reduce costs.

1.2 Manufacturing and Processing Expenses

Processing Inox involves several energy-intensive steps:

-

Melting and alloying – Combining iron with chromium, nickel, or molybdenum to achieve the desired grade.

-

Casting and rolling – Sheets, plates, or coils are formed under strict temperature control.

-

Finishing – Polishing, brushing, or coating to meet aesthetic and durability standards.

Each of these steps adds cost. For instance, producing a Metal Stainless Steel Sheet for a commercial railing project involves precise rolling and surface treatment, which can increase the material price by 15-25% compared to raw slabs.

1.3 Regional Price Variations

Inox material pricing differs across regions due to shipping costs, local labor rates, and trade tariffs. For example, a SS Steel Plate sourced in Europe may be 10-15% higher than an equivalent product manufactured in Southeast Asia. Local building codes can also influence the grade selection, indirectly affecting costs.

| Region | Typical Inox Price per Ton (USD) | Notes |

|---|---|---|

| North America | 2,500 – 3,200 | Higher labor and compliance costs |

| Europe | 2,700 – 3,400 | Premium grades preferred for construction |

| Southeast Asia | 2,100 – 2,800 | Lower labor, faster supply chain |

| Middle East | 2,300 – 3,000 | Import duties vary by country |

1.4 Supply and Demand Dynamics

Market fluctuations strongly impact Inox costs. High demand from sectors like architecture, automotive, and industrial equipment can drive prices up, especially for specialty grades. For example, stainless cladding for a new office building in Dubai can command higher material prices during peak construction seasons. Conversely, oversupply periods or reduced demand in slow construction months may temporarily reduce pricing.

Contractors often negotiate bulk orders or combine multiple small projects to stabilize costs. For example, sourcing a batch of Stainless Steel Metal Plate for a hotel facade project can secure better pricing than ordering piecemeal, without compromising quality.

2. Cost Breakdown by Inox Material Type

Understanding how different types of Inox material affect cost is crucial for project planning. Each grade has distinct chemical composition, mechanical properties, and typical applications that directly influence pricing.

2.1 Austenitic Stainless Steel

Austenitic stainless steel, such as 304 or 316 grades, dominates construction and kitchen applications due to its excellent corrosion resistance and ductility. Pricing depends heavily on nickel content—316 grade can cost 20-30% more than 304 due to higher nickel and molybdenum percentages. A practical example is fabricating Лим од не'рѓосувачки челик panels for a high-end restaurant facade. Contractors often follow these steps for optimal installation:

-

Cut sheets to precise dimensions.

-

Smooth edges using a finishing grinder.

-

Drill mounting points for seamless integration.

-

Secure panels with corrosion-resistant fasteners.

2.2 Ferritic Stainless Steel

Ferritic stainless steel offers lower cost alternatives with good corrosion resistance, particularly in mildly corrosive environments like indoor wall cladding or HVAC ducts. Prices are generally 15-25% lower than comparable austenitic grades. While less ductile, it handles large panel fabrication well. For example, a warehouse installation using Metal Stainless Steel Sheet can achieve long-term durability without the higher budget of austenitic steel.

2.3 Martensitic Stainless Steel

Martensitic stainless steel focuses on strength and hardness rather than corrosion resistance. It is ideal for tools, industrial blades, and structural components. Cost varies with carbon content—higher carbon martensitic steel is tougher but more expensive. A notable project could involve producing stair treads or railing components, where precision fabrication steps include:

-

Heat-treating to reach the required hardness.

-

Cutting with laser or water jet for tight tolerances.

-

Surface polishing to reduce roughness and prevent corrosion.

2.4 Duplex and Specialty Grades

Duplex stainless steels combine austenitic and ferritic properties, offering excellent strength and corrosion resistance, often used in offshore platforms, chemical plants, or high-end architectural projects. Specialty grades, like super duplex or high-molybdenum alloys, can cost 50-80% more than standard austenitic grades, reflecting their complex production and high alloy content. Contractors working on a chemical facility might follow this workflow:

-

Specify precise grade based on chloride resistance.

-

Procure from reliable suppliers to avoid inconsistencies.

-

Cut and weld using controlled procedures to maintain alloy integrity.

Choosing the right Inox grade is more than just cost—project longevity, exposure conditions, and fabrication complexity all matter. Bulk orders of SS Steel Plate или Stainless Steel Metal Plate often reduce per-unit cost, and selecting the correct grade avoids expensive replacements down the line.

3. Inox Material Pricing by Form

The shape or form of Inox material significantly impacts its price. Manufacturers set different rates for sheets, plates, coils, bars, and tubes due to production complexity, material yield, and application requirements.

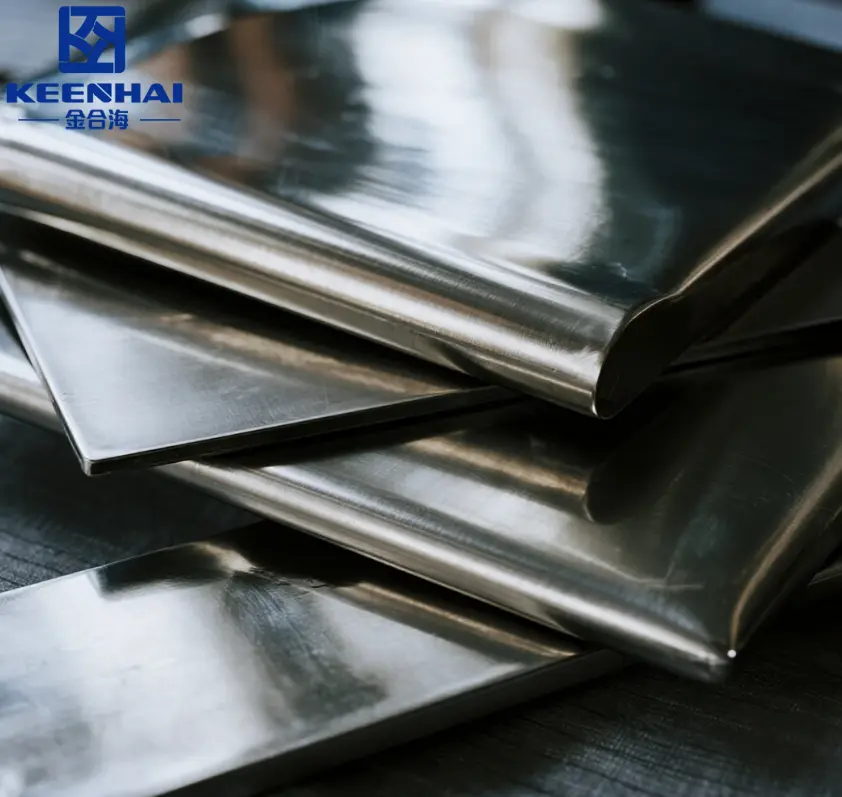

3.1 Sheets and Plates

Sheets and plates are the most common forms for construction, cladding, and industrial projects. Prices vary based on thickness, surface finish, and alloy grade. For instance, a 316-grade Stainless Steel Sheet with a brushed finish for a modern kitchen backsplash can cost $3,200 per ton, while a standard 304 sheet might be closer to $2,700 per ton. Installing sheets usually involves:

-

Measuring and cutting to fit the installation area.

-

Deburring and polishing edges to prevent corrosion.

-

Aligning panels carefully and securing them with stainless fasteners.

3.2 Coils and Strips

Coils and strips are often used in manufacturing appliances, automotive components, or ductwork. Pricing depends on width, thickness, and alloy composition. For example, a 2mm thick stainless coil for ductwork may range from $2,500 to $3,000 per ton. Fabrication steps include:

-

Uncoiling and flattening material.

-

Cutting strips to required lengths.

-

Edge treatment to maintain smoothness and safety during handling.

3.3 Bars and Rods

Bars and rods are widely used in structural elements, machinery, and railing systems. Solid round or square bars cost more than hollow variants due to higher material volume. A SS Steel Plate converted into bars for handrails might cost $2,800 to $3,400 per ton, depending on grade. Typical workflow includes:

-

Cutting rods to precise lengths.

-

Straightening and heat-treating as needed.

-

Drilling or threading for assembly in construction projects.

3.4 Tubes and Pipes

Tubes and pipes find use in plumbing, structural frameworks, and industrial pipelines. Seamless or welded pipes are priced differently; seamless tubes generally carry a premium due to more complex manufacturing. For example, 316-grade stainless tubing for a coastal railing system can cost $3,500 per ton, while 304 welded tubes may be around $2,900 per ton. Installation usually follows:

-

Measuring and cutting to site specifications.

-

Polishing welds or joints to prevent corrosion.

-

Securing in place using clamps or brackets suitable for outdoor exposure.

4. Market Price Trends in 2025

In 2025, Inox material prices are influenced by historical trends, short-term market dynamics, and long-term projections. Staying aware of these trends allows buyers and contractors to make informed purchasing decisions.

4.1 Historical Price Comparison

Over the past five years, 304-grade stainless steel sheets have seen steady growth in price due to rising nickel and chromium costs. For example, a ton of 304 Stainless Steel Sheet increased from $2,200 in 2020 to $2,700 in 2024. Meanwhile, 316-grade sheets, which contain more nickel and molybdenum, rose from $2,600 to $3,200 per ton in the same period. Tracking historical data helps predict when to lock in prices for large construction projects or bulk orders.

4.2 Short-Term Fluctuations

Short-term price fluctuations often respond to global supply chain events, energy costs, and sudden demand surges. For instance:

-

A spike in global nickel prices can increase Inox sheet costs by 5-10% within a month.

-

Temporary port closures or shipping delays can affect regional pricing, especially for imported SS Steel Plate.

-

Seasonal demand from construction and manufacturing industries may drive up quotes in peak months.

Contractors working on facade installations or industrial equipment fabrication often monitor supplier quotes weekly to optimize timing for procurement and avoid sudden price hikes.

4.3 Long-Term Projections

Analysts forecast moderate growth in Inox pricing throughout 2025, with 304-grade sheets expected to stabilize around $2,800–$2,900 per ton and 316-grade sheets at $3,200–$3,350 per ton, assuming no major disruptions in raw material supply. Factors influencing these projections include:

-

Sustainable mining practices affecting nickel and chromium availability.

-

Energy costs for steel production, particularly in regions with high electricity rates.

-

Expansion of high-end construction projects in emerging markets driving demand for specialty grades.

Companies aiming for large-scale deployments, like commercial kitchen renovations or industrial panel installations, benefit from securing supply contracts early. Bulk procurement of Stainless Steel Metal Plate can lock in prices and reduce exposure to market volatility.

5. Purchasing Considerations for Inox Material

When buying Inox material in 2025, several practical considerations can help you optimize cost without compromising quality. Knowing how to navigate pricing structures, discounts, and logistics ensures better budgeting for construction, fabrication, or industrial projects.

5.1 Wholesale vs. Retail Pricing

Wholesale pricing is generally lower per ton compared to retail, but it often requires minimum order quantities. For example, purchasing a ton of Лим од не'рѓосувачки челик from a wholesale supplier can be $200–$400 cheaper per ton than buying small retail batches. Retail options are more flexible but usually include higher markups due to packaging, handling, and smaller quantities. Contractors installing kitchen panels or building facade cladding often weigh total project needs before choosing wholesale or retail to maximize cost efficiency.

5.2 Bulk Order Discounts

Suppliers typically provide tiered discounts based on quantity. Ordering multiple tons of SS Steel Plate или Metal Stainless Steel Sheet can lower the effective cost per ton by 5–15%, depending on the grade and form. Steps to leverage bulk discounts effectively include:

-

Consolidate all material needs for the upcoming projects.

-

Verify quality specifications and alloy grade with the supplier.

-

Negotiate delivery schedules to match project timelines and storage capabilities.

-

Confirm payment terms and any additional services like cutting or surface finishing.

5.3 Shipping and Handling Costs

Logistics can significantly influence the final cost of Inox material. Shipping rates vary by distance, weight, and handling requirements:

-

Standard freight for domestic shipments is generally predictable, but oversized sheets or heavy plates may require specialized transport.

-

Coastal or international deliveries often include port fees, customs clearance, and insurance, which can add $100–$300 per ton to the final price.

-

Proper packaging and handling are essential to prevent surface damage, scratches, or corrosion during transit, especially for polished Stainless Steel Metal Plate destined for architectural applications.

Making decisions on purchasing Inox material involves balancing price, grade, quantity, and delivery logistics. By understanding wholesale advantages, bulk discounts, and shipping intricacies, buyers can secure high-quality stainless steel for projects without unexpected cost overruns.