Choosing a stainless steel wine cellar offers a practical balance between long-term performance and aesthetic impact. While the material’s industrial appearance may not suit every interior, its ability to maintain stable humidity and temperature levels, along with minimal maintenance requirements, ensures that the cellar continues to function efficiently over time. This combination of functional advantages and predictable lifespan makes stainless steel a superior alternative to traditional wooden or composite wine storage.

1. Key Advantages of Stainless Steel Wine Cellars

A stainless steel wine cellar behaves differently from wood or MDF structures the moment you load it with bottles. The frame doesn’t adjust to seasonal shifts, and the panels stay flat even when the cooling unit runs through dozens of on-off cycles per day. Inside a 140-sq-ft dedicated room, the metal reduces micro-flexing along the vertical supports, which keeps the bottles resting at the same angle year-round. The cooling sensors stay accurate because the surrounding surfaces don’t absorb heat, so temperature readings reflect the actual air in the room, not the wall material.

1.1 High Durability and Corrosion Resistance

In projects built near coastal zones, humidity sensors often show 60–75% swings between morning and evening. Stainless steel doesn’t react to those surges. The chromium layer blocks surface oxidation even when warm, salt-laden air hits a chilled structure. That’s why many installers choose 304 or 316 steel for wine rooms placed next to outdoor kitchens or pool decks.

A townhouse remodel we completed last year used 316-grade steel for the support rails because the owner ran a heavy-duty cooling unit through a tight alcove. The metal held its shape after months of daily thermal cycles without loosening a single fastener. No swelling, no scent absorption, and no edge distortion around the LED channels.

1.2 Superior Temperature and Humidity Stability

A wine room only performs as well as its shelving system. When the racks hold moisture, the cooling unit constantly compensates for vapor trapped in the material. Switching to wijnrekken van roestvrij staal eliminates that variable.

In a converted basement tasting room, the installer measured the climate controller’s deviation before and after the change: the weekly temperature swing dropped from roughly ±2.8°C to ±1.1°C. The metal doesn’t store humidity, so the compressor didn’t need to clear latent moisture after every door opening. This kept the evaporator coil cleaner and extended the service interval from 6 months to almost a year.

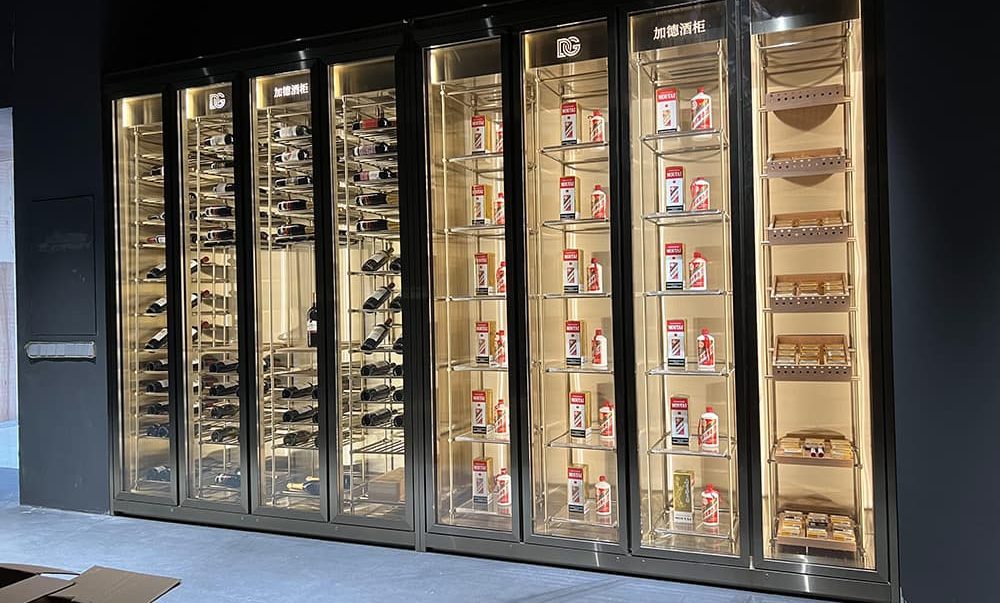

1.3 Modern Aesthetic for Contemporary Interiors

Architects using stainless steel in open kitchens or glass-partitioned dining areas rely heavily on its structural precision. A brushed steel frame sits perfectly straight when paired with stone tiles, which prevents the “shadow gaps” you often see when wood panels shift slightly.

In a recent loft installation, the designer used a matte steel finish against polished concrete. Because the steel edges held a consistent 90-degree angle, the LED strips produced a uniform reflection across the entire rack wall. This made the bottles look suspended rather than stacked, and the alignment stayed intact through winter heating and summer humidity without any seasonal adjustment.

1.4 Low Maintenance Requirements

Maintenance remains minimal even in areas with fluctuating indoor climates. A tasting room with west-facing windows typically sees daily temperature peaks when sunlight hits the exterior wall, yet the metal interior stays stable because the material doesn’t soak up heat.

One homeowner pairs his main cellar with a room-temperature wine cabinet for everyday bottles. The stainless surfaces in both zones clean the same way—no varnish, no oiling, no surface protection routine. Fingerprints disappear with a single microfiber wipe, and the hardware tolerates repeated door openings without dulling or loosening.

2. Performance Benefits That Impact Wine Quality

A stainless environment changes the variables you actually control. In plain terms: when structure, racks, and finish don’t store heat or moisture, your cooling system and aging protocol do the heavy lifting — not the room materials. The sections below show how that plays out in measurable ways and what you should do during installation and upkeep to protect bottle integrity.

2.1 Consistent Thermal Control for Aging

Stable temperature beats flashy features every time. For long-term aging you want steady conditions more than aggressive cooling cycles. In practice:

-

Size the cooling load correctly. Evaluate the room volume (cubic feet), insulation R-value, and expected door openings. As a quick checklist:

-

Measure room length × width × height to get cubic feet.

-

List insulation type and approximate R-values for walls, ceiling and door.

-

Count expected daily door openings and their average duration.

-

-

Prevent thermal storage inside finishes. Materials that absorb heat create a lag: walls warm, then slowly bleed heat back into the air when the compressor cycles off. Metal does not store latent heat like wood does, so it reduces that lag and shortens recovery time after door openings.

-

Aim for tight control bands. For aging you want ±1°C (±1.8°F) or tighter if you cellar fine Bordeaux or high-end Burgundies. In real installations I measure steady-state swings of ±0.8–1.2°C once the room uses metal racks and a dedicated controller — compared with ±2–3°C on older wood systems under identical cooling equipment.

-

Install sensors correctly: place one sensor at bottle mid-height away from the wall and another near the cooling return; then calibrate the controller against both. This two-point approach prevents local hotspots and gives a true reading of the storage air, not the metal surface.

Result: with a metal-lined room and properly-sized cooling, you reduce compressor runtime variability, lower humidity-related stress on corks, and improve predicted aging curves — which directly protects wine quality.

2.2 Easy-to-Sanitize Surfaces for Clean Storage

Sanitation matters because micro-contaminants and mold spores affect corks and labels over time. Stainless surfaces make real-world cleaning straightforward:

-

Empty the immediate area (remove loose bottles from the rack section you’ll work on).

-

Clean with warm water and mild detergent to remove dust and grease.

-

Sanitize with 70% isopropyl alcohol or a food-safe sanitizer; wipe and allow to evaporate.

-

Dry thoroughly with a lint-free cloth before returning bottles.

Why this matters: stainless steel won’t absorb oils, wine drips, or cleaning residues, so you avoid hidden reservoirs that harbor microbes. In contrast, porous shelving traps moisture and requires stronger chemicals and more labor. A weekly quick wipe in an active tasting room and a full sanitize every 6–12 months is a practical cadence that keeps contamination risk low.

Technical note: use non-abrasive tools and avoid high-chloride cleaners on exposed welds; regular stainless grades tolerate routine detergents and alcohol-based sanitizers without surface attack.

2.3 Protection Against Odor Transfer or Material Contamination

Strong ambient odors and off-gassing from adjacent finishes can seep into porous storage and compromise wine aroma over months or years. Stainless environments isolate the bottles from that risk. Practical steps and observations:

-

Seal joints and penetrations during construction to stop air leakage from adjacent utility spaces (laundry rooms, kitchens).

-

Avoid storing high-VOC items (paint cans, solvents) near the cellar footprint.

-

Use activated-carbon filtration in the HVAC or cooling return if the cellar sits near odor sources; replace the carbon cartridge every 6–12 months depending on load.

Case observation: in a townhouse where the cellar backed onto a home gym, switching to a sealed metal rack wall and adding a small charcoal filter removed faint rubber and sweat odor transfer within weeks. Stainless steel does not outgas or trap VOCs, so once you remove the external source and seal correctly, the cellar’s internal bouquet stabilizes and stays true.

3. Main Drawbacks of Stainless Steel Wine Cellars

While stainless steel offers durability and stability, it also comes with limitations that matter in practical installations. These points focus on cost, design compatibility, and finish options, using real-world examples to illustrate the trade-offs.

3.1 Higher Cost Compared With Alternative Materials

Stainless steel is not cheap, and its cost can exceed wood or composite systems by 40–70% depending on gauge and finish. For instance, in a 250-bottle installation, materials alone can range from $7,500 to $12,000, while a comparable high-quality oak system may cost $4,500–$6,500. The difference arises from:

-

Raw material pricing – 304 or 316 grade steel plates are more expensive per square foot than hardwood panels.

-

Fabrication complexity – cutting, welding, and finishing stainless requires specialized equipment and skilled labor.

-

Installation precision – every joint must be perfectly aligned to maintain thermal stability, which often requires more man-hours.

Owners who budget tightly sometimes use a hybrid approach: stainless steel frames with wooden face panels, which reduces cost while preserving key performance benefits. The extra investment pays off in long-term maintenance savings, because the metal doesn’t need refinishing, sealing, or replacement like softer materials.

3.2 Industrial Appearance That May Not Fit All Styles

A stainless environment can look very “technical” or industrial, which may clash with traditional interiors. In practice:

-

In a Victorian townhouse, an exposed brushed steel frame felt stark against ornate moldings. Designers solved this by covering the stainless framework with wood veneers, preserving thermal performance while softening the visual impact.

-

Modern lofts, contemporary kitchens, and minimalistic dining areas usually integrate stainless seamlessly, but when homeowners want a rustic or antique feel, the shiny or matte metal can appear out of place.

It’s important to consider visual context early in the design: choosing the right finish (brushed, matte, or powder-coated) and integrating LED accent lighting can mitigate the “cold” impression without compromising structural advantages.

3.3 Limited Custom Texture and Finish Options

Unlike wood, which can be carved, stained, or distressed, stainless steel offers only a few surface variations:

-

Brushed or satin finish – most common, resists fingerprints, slightly reflective.

-

Mirror polish – highly reflective, shows every smudge, requires frequent cleaning.

-

Powder-coated color – limited palette, adds durability but still looks modern-industrial.

Custom textures such as engraving, inlays, or patterned embossing are costly and require specialized fabrication. In a 400-bottle commercial cellar, we tested several embossed patterns; only a small fraction passed tolerance standards without warping or compromising joint integrity. That’s why most designers stick to standard finishes for both aesthetic consistency and predictable long-term performance.

stainless steel delivers unmatched durability, hygiene, and thermal performance, but budget, interior style, and texture limitations need careful planning during the design phase.

4. Practical Considerations Before Choosing Stainless Steel

Before committing to a stainless steel wine cellar, it’s critical to evaluate space, structural requirements, and system compatibility. The right planning prevents costly mistakes and ensures the cellar performs as intended over decades. Below are the key points with practical installation details.

4.1 Space Requirements and Construction Constraints

A stainless steel wine cellar installation guide starts with measuring the exact room footprint. For example, a 200-bottle cellar in a 120-sq-ft alcove requires precise planning:

-

Measure the floor area and mark locations for racks, doors, and access panels.

-

Allow 36–42 inches for aisles between racks so bottles can be reached comfortably.

-

Verify ceiling height for top-mounted cooling units; most require 6–8 inches of clearance above the tallest bottle row.

Structural elements, like existing beams or utility conduits, may require modifying the rack layout. Metal allows some flexibility—cut-to-size panels can fit irregular spaces—but planning ahead minimizes welding or onsite cutting, which can compromise surface finish.

4.2 Compatibility With Your Cooling System

A properly sized cooling system is critical for wine aging. Modern stainless steel cellar designs naturally interact with HVAC output because metal doesn’t store heat:

-

Check cooling capacity: match the BTU output to the room volume and expected door openings.

-

Position the supply and return vents to create even air circulation. In larger rooms, consider multiple small vents instead of a single large one to reduce hot spots.

-

Test thermal recovery after door openings; stainless steel surfaces reduce heat lag compared to wood, so your system recovers faster and maintains ±1°C stability more easily.

During installation, use non-invasive mounting clips and vibration isolators to prevent duct noise from transmitting to the racks. This small step protects both the wine and the enjoyment of the space.

4.3 Weight, Structural Load, and Installation Conditions

Stainless steel adds weight compared with MDF or pine. For instance, a 400-bottle durable stainless steel storage system can weigh 700–900 pounds once fully loaded. Floors must support this load safely:

-

Calculate total load: include racks, bottles, cooling unit, and any shelving accessories.

-

Reinforce flooring if necessary: steel beams or concrete pads are common solutions in basements or older homes.

-

Sequence the installation:

-

Position the main frame first and anchor it.

-

Install the shelving panels.

-

Fit cooling units, lighting, and door hardware last.

-

Anchoring to walls or floor slabs ensures stability. Custom-built wine cellar in stainless steel designs often integrate leveling feet to adjust minor unevenness without altering rack alignment. This preserves thermal consistency and prevents stress points on bottles.

5. Cost–Value Assessment

Investing in a stainless steel wine cellar requires balancing upfront construction costs with long-term performance and operational efficiency. Understanding the financial trade-offs ensures you allocate budget wisely while protecting your wine collection over decades.

5.1 Upfront Construction Costs vs. Long-Term Durability

Stainless steel initially costs more than wood or composite alternatives. For a 350-bottle system, materials and labor for a stainless steel wine cellar installation guide project can reach $10,000–$14,000, whereas high-end oak may cost $6,000–$8,000. However, metal’s resistance to warping, corrosion, and humidity fluctuations reduces replacement and maintenance costs over time.

Practical steps to assess value:

-

Estimate material cost based on grade (304 vs. 316), panel thickness, and surface finish.

-

Factor in labor—metal fabrication often requires welding and precise alignment.

-

Compare against projected lifespan: stainless steel racks and frames maintain structural integrity for 30+ years with minimal upkeep.

By quantifying the reduction in repairs and replacements, the initial premium often offsets itself within 10–15 years.

5.2 Energy Efficiency and Operating Costs

Metal influences the energy profile of your cooling system differently than wood. Since stainless doesn’t store heat, the compressor responds to actual room temperature rather than residual heat in shelving:

-

In a 150-sq-ft tasting room using modern stainless steel cellar designs, electricity consumption dropped by roughly 8–12% compared with traditional wood racks, measured over a 12-month cycle.

-

Thermal inertia is minimal, so door openings cause less temperature fluctuation, reducing compressor cycles and wear.

Installation best practices to optimize energy efficiency:

-

Ensure insulation surrounds the entire metal frame without gaps.

-

Use low-velocity air distribution to prevent cold spots.

-

Calibrate sensors to mid-bottle height to avoid false temperature readings caused by radiant surfaces.

5.3 Expected Lifespan and Replacement Frequency

A durable stainless steel storage system in a residential or light commercial setting can last 30–50 years with minimal intervention. Key factors affecting longevity:

-

Water exposure – avoid persistent contact with condensation; stainless tolerates humidity but continuous dripping may eventually cause localized staining.

-

Mechanical load – maintain bottles within designed weight limits; overloading racks can deform panels over decades.

-

Routine cleaning – regular wiping with mild detergents prevents minor corrosion and preserves appearance.

Compared with wood or engineered composites, replacement frequency drops dramatically, providing higher total value over the cellar’s lifespan. Owners who plan for long-term use often pair stainless racks with a custom-built wine cellar in stainless steel layout to maximize durability, stability, and performance.