One of the biggest mistakes when choosing inox is prioritizing low upfront cost over long-term performance. For example, low-grade stainless steel may seem affordable, but in marine or industrial environments, it can corrode within months. Buyers should evaluate alloy composition, tensile strength, and fatigue resistance. Using high-quality materials such as Stainless Steel Sheet ensures structural integrity, reduces maintenance frequency, and prevents unexpected replacements, saving time and money in the long run.

1. Ignoring Proper Alloy Grades

1.1 Selecting Low-Grade Inox for High-Corrosion Environments

One of the most common mistakes in material selection is opting for low-grade inox in high-corrosion settings. Coastal balconies, marine platforms, and chemical plant installations face constant exposure to salt, moisture, and industrial pollutants. Using low-grade stainless steel in these environments leads to pitting, surface discoloration, and accelerated rust formation, significantly shortening the material’s lifespan.

For instance, a seaside restaurant initially installed standard 304 stainless steel sheets, which began showing rust streaks within 18 months. Switching to stainless steel sheets with higher molybdenum content solved the problem, preserving both the structural integrity and visual appeal. Proper selection involves:

-

Assessing environmental factors like salt concentration, humidity, and pollutant exposure.

-

Choosing an alloy with appropriate corrosion-resistant elements, such as chromium and molybdenum.

-

Considering surface finish and protective coatings to enhance durability further.

1.2 Misunderstanding Alloy Composition Impact on Strength and Durability

Many engineers overlook how small variations in alloy composition affect strength, ductility, and resistance to fatigue. For load-bearing projects like staircases, handrails, and industrial frames, using an inappropriate grade can compromise safety and increase maintenance costs.

Key differences among common stainless steel alloys can be seen in the table below:

| Alloy Type | Chromium (%) | Nickel (%) | Molybdenum (%) | Key Performance | Typical Applications |

|---|---|---|---|---|---|

| 304 | 18–20 | 8–10 | 0 | Moderate corrosion resistance, good ductility | Indoor panels, kitchen equipment |

| 316 | 16–18 | 10–14 | 2–3 | High corrosion resistance, strong in marine environments | Offshore railings, chemical plant structures |

| 2205 Duplex | 22–23 | 5–6 | 3 | Very high strength and corrosion resistance | Heavy-duty industrial structures, structural beams |

Projects like rooftop terraces or chemical storage tanks demonstrate how choosing the wrong alloy leads to visible surface degradation, frequent repairs, and increased long-term costs. SS Steel Plate is often preferred in structural applications for its combination of strength and corrosion resistance.

1.3 Failing to Account for Environmental and Load Demands

Beyond composition, ignoring the relationship between environmental exposure and load requirements often results in underperforming installations. For example, outdoor stair railings in coastal areas must resist both salt corrosion and mechanical stress from daily use. Skipping this evaluation can cause warping, micro-cracking, or even structural failure. High-quality stainless steel provides the dual benefit of mechanical robustness and chemical resistance, ensuring safety and longevity.

2. Overlooking Corrosion Resistance Requirements

2.1 Failing to Match Material with Exposure Conditions (Marine, Industrial, Outdoor)

One critical mistake is selecting stainless steel without considering the environment. Materials that perform well indoors may fail in marine or industrial conditions. For instance, a coastal hotel installed 304 stainless steel railings, expecting standard corrosion resistance, but heavy salt exposure caused pitting within 2 years. Switching to stainless steel sheets with higher molybdenum content eliminated rust formation and maintained aesthetic appeal.

Steps to ensure proper material selection:

-

Identify the primary exposure environment: marine, industrial, or outdoor.

-

Evaluate humidity, salinity, and chemical exposure levels.

-

Match the alloy grade to these conditions, considering enhanced corrosion-resistant elements such as chromium, nickel, and molybdenum.

-

Consider additional surface finishes or coatings to further protect the material.

-

Conduct small-scale tests in situ to observe performance before full installation.

Projects like outdoor staircases, rooftop terraces, and chemical plant railings demonstrate that skipping these steps can result in frequent maintenance, surface degradation, and safety risks.

2.2 Assuming All Stainless Steel Performs Equally Against Rust

A second common error is believing that all stainless steel alloys resist rust equally. Differences in alloy composition and microstructure have a dramatic impact on performance. For example, 316 stainless steel outperforms 304 in salty or chemical-heavy environments, while duplex grades provide superior mechanical strength alongside corrosion resistance.

| Alloy Type | Key Corrosion Resistance Features | Ideal Applications |

|---|---|---|

| 304 | Good general resistance but limited in high-chloride environments | Indoor panels, kitchen appliances |

| 316 | High resistance to chloride-induced corrosion | Marine railings, outdoor furniture |

| 2205 Duplex | Excellent resistance to pitting and crevice corrosion, high strength | Offshore structures, heavy-duty industrial frames |

In addition to selecting the right grade, installation and maintenance practices play a crucial role in corrosion resistance. For example, outdoor railings exposed to acid rain should be cleaned quarterly and inspected for surface micro-damage, ensuring long-term durability. Using inappropriate grades or neglecting environmental factors leads to costly repairs and compromised structural integrity.

3. Neglecting Mechanical Load Considerations

3.1 Choosing Material Without Verifying Tensile or Yield Strength

A frequent mistake in structural projects is picking stainless steel without checking its tensile or yield strength, leading to deformation or catastrophic failure under load. For example, a commercial balcony used standard 304 stainless steel panels, assuming they could handle heavy foot traffic, but excessive deflection occurred because the yield strength was insufficient for concentrated loads. Choosing SS Steel Plate with verified tensile and yield data ensures the structure performs reliably under expected stresses.

Steps to correctly match material to load requirements:

-

Calculate maximum expected load and distributed weight for each structural component.

-

Consult mechanical property data sheets to select materials with sufficient tensile and yield strength.

-

Factor in temperature, corrosion, and long-term creep effects.

-

Where applicable, choose high-strength or duplex grades to reduce material thickness while maintaining structural integrity.

-

Conduct a small-scale mock-up or finite element analysis (FEA) to validate assumptions before final fabrication.

Projects like rooftop terraces, pedestrian bridges, and industrial racks clearly show that neglecting these steps can lead to visible sagging, costly reinforcement, or safety hazards.

3.2 Ignoring Fatigue and Impact Resistance Needs for Structural Projects

Another common oversight is assuming stainless steel inherently handles repeated stress and impact. In reality, fatigue resistance varies dramatically between alloys, and repeated loads can lead to micro-cracks or eventual failure. For example, an outdoor staircase in a coastal facility used a standard sheet without assessing cyclic loads. Over 3 years, cracks appeared near weld joints due to inadequate fatigue resistance.

| Alloy | Fatigue Resistance | Impact Resistance | Ideal Applications |

|---|---|---|---|

| 304 | Moderate | Moderate | Indoor railings, light-duty structures |

| 316 | உயர் | உயர் | Marine environments, outdoor heavy traffic |

| Duplex | Very High | Excellent | Bridges, offshore platforms, industrial load-bearing structures |

Best practices for ensuring mechanical durability:

-

Identify cyclic and impact loads expected over the lifetime of the structure.

-

Select stainless steel grades tested for fatigue and impact resistance.

-

Incorporate adequate thickness and reinforcement at high-stress points.

-

Apply proper welding and finishing techniques to avoid stress concentrators.

-

Schedule periodic inspections for high-load components to detect early fatigue signs.

By paying attention to tensile, yield, and fatigue performance, structural designers prevent long-term issues and guarantee safety, especially in high-traffic or industrial settings.

4. Underestimating Surface Finish and Maintenance Needs

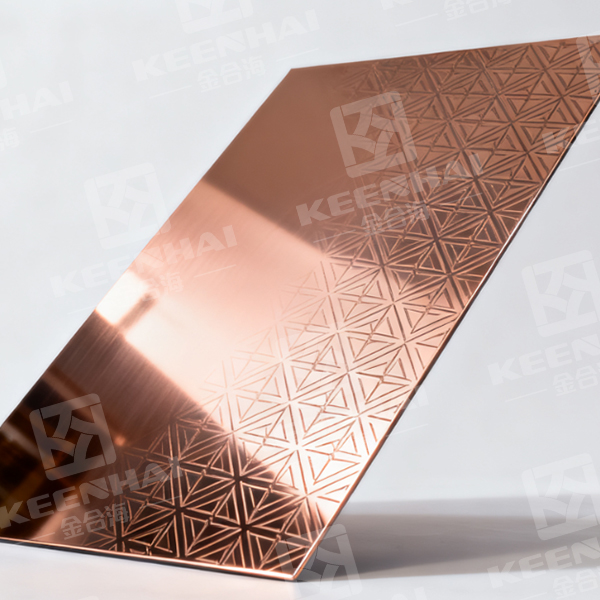

4.1 Picking Finishes Unsuitable for Heavy Wear or Scratch-Prone Areas

A frequent mistake in stainless steel projects is selecting a finish that cannot withstand high-traffic or abrasive environments. For instance, a commercial kitchen installed mirror-finish stainless steel panels in prep areas, assuming they looked premium and were easy to clean. Within months, visible scratches and surface dulling appeared, highlighting the importance of choosing a finish that aligns with functional demands.

Practical steps to select the right finish:

-

Identify the expected wear level: high foot traffic, repeated tool contact, or moving equipment.

-

Compare available finishes: brushed, matte, or mirror. Brushed finishes often conceal scratches better, while mirror finishes highlight every mark.

-

Consider protective coatings or passivation treatments for high-impact zones.

-

Assess environmental exposure: coastal areas or industrial settings may accelerate surface corrosion, even on premium stainless steel.

-

Conduct small-scale mock-ups to test the appearance and wear over time.

In industrial corridors or busy restaurants, using Metal Stainless Steel Sheet with a suitable brushed or textured finish can significantly reduce maintenance headaches while maintaining a polished aesthetic.

4.2 Not Accounting for Long-Term Cleaning or Coating Requirements

Many designers overlook the ongoing maintenance needs of stainless steel surfaces, assuming “once installed, it stays perfect.” In reality, improper cleaning, neglecting passivation, or using incompatible chemicals can lead to corrosion or staining over time. For example, a rooftop terrace with stainless steel balustrades faced discoloration because cleaning staff used acidic detergents without considering alloy-specific guidelines.

Steps to ensure long-term durability:

-

Determine the recommended cleaning frequency based on environment: weekly for outdoor installations, daily for high-contact indoor areas.

-

Use neutral pH detergents and soft cloths or microfiber pads to prevent scratching.

-

Schedule periodic inspection and touch-up of protective coatings or anodized layers.

-

Apply corrosion inhibitors or protective wax where exposure to harsh elements is unavoidable.

-

Train maintenance personnel to follow alloy-specific cleaning protocols.

By proactively matching finishes and cleaning routines to the environment, stainless steel retains its strength and visual appeal for decades. Even in high-humidity or industrial settings, careful planning prevents costly replacements and ensures surfaces maintain a professional, polished appearance.

5. Focusing Solely on Initial Cost

5.1 Prioritizing Low Price Over Longevity and Performance

A common pitfall in material selection is choosing the cheapest stainless steel option without considering long-term performance. For example, a small café installed low-cost stainless steel countertops assuming initial savings would outweigh all other factors. Within 12 months, visible corrosion and surface pitting occurred due to frequent exposure to acidic cleaning solutions and food ingredients, demonstrating that initial cost savings often lead to higher repair and replacement expenses.

Steps to evaluate materials beyond price:

-

Compare alloy grades and their corrosion resistance for the specific environment.

-

Examine tensile strength and fatigue resistance to ensure the material can withstand daily operational stress.

-

Assess surface finish suitability for expected wear; brushed or textured finishes often outperform mirror finishes in high-contact areas.

-

Factor in cleaning protocols and chemical exposure to predict long-term durability.

-

Review manufacturer warranties and performance certifications to verify claims.

Using துருப்பிடிக்காத எஃகு தாள் from reputable suppliers ensures that the material delivers both aesthetic appeal and functional longevity, which often justifies slightly higher upfront costs.

5.2 Ignoring Lifecycle Costs, Maintenance, and Replacement Frequency

Focusing only on upfront price ignores lifecycle costs, which include cleaning, maintenance, and eventual replacement. In a hotel renovation, low-cost stainless steel balustrades were selected, but over five years, the property incurred multiple maintenance contracts, polishing, and partial replacements, which ultimately doubled the initial budget.

Steps to calculate total lifecycle cost:

-

Estimate annual maintenance frequency and cost based on environmental exposure.

-

Evaluate expected lifespan of different alloys under realistic conditions.

-

Factor in downtime or disruption costs for replacement or repair.

-

Consider resale or salvage value if applicable.

-

Compare initial cost vs projected 5–10 year lifecycle costs to make an informed decision.

For industrial or high-traffic projects, choosing premium inox sheets or properly specified SS Steel Plate can reduce lifecycle expenses, prevent frequent replacements, and maintain safety standards over time.