Choosing a professional Stainless Steel Wine Cabinet Manufacturer allows you to access fully customized solutions, from modular racks to climate-controlled cabinets. Manufacturers handle everything in-house, including precision welding, assembly, and surface finishing, so every cabinet fits the intended space perfectly while maintaining structural integrity and long-term durability.

1. Manufacturing Capabilities and Production Scope

Delivering high-quality wine storage solutions goes beyond simple assembly. True manufacturing strength is reflected in material handling, precise engineering, and adaptability to real project demands. In commercial projects like hotel lobbies, private tasting rooms, and wine bars, production scope determines whether a design becomes a flawless, functional installation or remains theoretical. Our facilities handle projects from single custom units to large-scale deployments, ensuring every piece meets strict standards before leaving the workshop.

1.1 In-House Fabrication of Stainless Steel Wine Cabinets

All core processes happen in-house, including CNC cutting, bending, TIG welding, and finishing. Controlling every step internally allows immediate adjustments and guarantees perfect alignment, consistent welds, and seamless surfaces.

For instance, in a hotel lobby project where a custom stainless steel wine cabinet was integrated into a stone and wood feature wall, every joint and edge had to meet millimeter-level tolerances. Internal fabrication allowed our team to adjust dimensions on-site, ensuring a flawless fit and visual continuity.

Typical workflow includes:

-

Inspecting stainless steel sheets for flatness and surface quality.

-

Cutting and bending according to precise design drawings.

-

Welding frames and supports, then grinding joints to create smooth surfaces.

-

Performing assembly checks before finishing treatments.

This process ensures predictable strength, visual consistency, and functional reliability across both standard and custom units.

1.2 Standard vs Custom Wine Cabinet Manufacturing

Our production covers both standard models and fully custom builds. Standard units suit projects with tight deadlines, while custom solutions accommodate unusual layouts, ceiling heights, or unique display requirements. The choice impacts engineering, lead time, and cost.

| Aspect | Standard Units | Custom Units |

|---|---|---|

| Dimensions | Pre-defined | Fully tailored to project |

| Design Flexibility | Limited | Full customization |

| Lead Time | Short | Varies by complexity |

| Application | Retail spaces, repeat orders | Hotels, private wine rooms |

| Structural Adjustments | Minimal | Engineered for unique requirements |

Custom projects often blend open stainless steel wine racks with enclosed cabinets, offering both display and storage. This configuration is particularly effective in tasting rooms or commercial wine bars, where presentation and accessibility are equally important. By designing with real-world installation needs in mind, we deliver solutions that are both practical and visually compelling.

1.3 Materials, Grades, and Surface Finishes Available

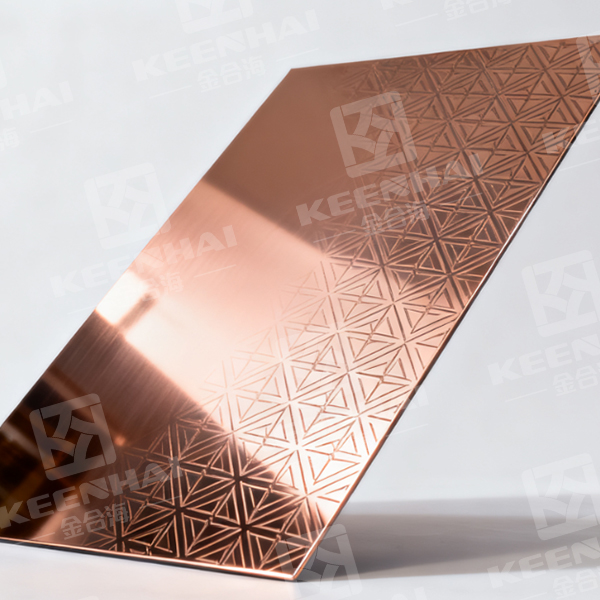

Material selection defines durability, appearance, and long-term performance. Most projects use 304 or 316 stainless steel, depending on humidity and environmental exposure. Surface treatments—including brushed, mirror, or PVD finishes—affect both aesthetics and maintenance needs.

In non-refrigerated environments, airflow, rack spacing, and structural reinforcement matter more than insulation. Hybrid units combining racks and enclosed storage require strong framing to support bottle weight while preserving elegant lines. This level of material control ensures that every finish, weld, and edge behaves reliably once installed, not just in the workshop.

2. Custom Stainless Steel Wine Cabinet Solutions

Custom solutions define the difference between a standard wine cabinet and a fully tailored storage experience. High-end projects demand cabinets that precisely fit the available space, accommodate exact bottle counts, and seamlessly integrate with architectural features. Our manufacturing process ensures that every custom unit meets these expectations while maintaining structural integrity and aesthetic appeal.

2.1 Size, Layout, and Capacity Customization

Every project starts with measuring the installation space and confirming storage requirements. For example, in a private tasting room, the ceiling height, wall angles, and floor load capacity all affect cabinet dimensions. Customization includes:

-

Determining total bottle capacity based on collection size.

-

Designing modular sections for flexible layout options.

-

Adjusting shelf spacing to accommodate varying bottle shapes.

-

Ensuring built-in alignment with walls, lighting features, or adjacent furniture.

By carefully planning the layout, our team delivers cabinets that are both functional and visually harmonious. In cases requiring specialized bottle orientations, such as Champagne or magnum formats, we use reinforced stainless steel supports to prevent sagging while keeping shelves flush and organized. This approach applies to all custom stainless wine storage solutions, whether they are integrated into tasting rooms, commercial bars, or home wine cellars.

2.2 Cooling Systems, Temperature Zones, and Humidity Control

For climate-sensitive collections, cabinets must maintain precise environmental conditions. We design multi-zone cooling systems that allow:

-

Setting separate temperature ranges for reds, whites, and sparkling wines.

-

Controlling humidity levels to prevent cork shrinkage or mold growth.

-

Monitoring internal air circulation to avoid hot spots or condensation.

-

Integrating quiet, energy-efficient compressors suitable for indoor environments.

Advanced features, such as variable-speed fans and dual compressors, allow room-specific temperature-controlled wine cabinets to operate reliably even in high-traffic hospitality settings. By combining temperature zoning with custom layouts, our cabinets protect delicate collections while maintaining easy access for staff or guests.

2.3 Glass, Lighting, and Door Configuration Options

Custom cabinets also incorporate finishes and features that enhance both visibility and presentation. Options include:

-

Tempered or laminated glass doors with UV protection.

-

Integrated LED lighting along shelves and display areas.

-

Soft-close or automated door mechanisms for silent operation.

-

Choice of handle types, hinges, and frame finishes to match surrounding decor.

By combining these elements, the final installation not only stores wine securely but also highlights the collection in a professional, showroom-quality environment. For high-traffic tasting areas, we often integrate open display racks with enclosed sections, balancing aesthetic appeal with operational efficiency. In these cases, custom stainless steel wine racks may be used to optimize display without compromising capacity.

3. Quality Control and Manufacturing Standards

Ensuring consistent quality in stainless steel wine storage solutions requires a structured manufacturing process combined with rigorous inspections. Every cabinet or rack we produce undergoes multiple checkpoints, from welding and assembly to surface finishing and pre-shipment verification. This approach guarantees both structural integrity and long-term performance, especially in demanding commercial environments such as hotels, private tasting rooms, or wine bars.

3.1 Precision Welding, Assembly, and Structural Integrity

The foundation of durable wine cabinets lies in accurate welding and assembly. Our process emphasizes:

-

Using CNC-guided fixtures for welding frames and supports, ensuring alignment within millimeters.

-

TIG welding to maintain smooth, visually clean joints, critical for weight-bearing shelves.

-

Reinforcing load-bearing points, especially for hybrid units combining open racks with enclosed cabinets.

-

Performing assembly checks to verify dimensional accuracy and cabinet stability before finishing.

In projects where stainless steel wine cabinets are integrated into high-traffic areas, precise welding prevents frame warping over time, while reinforced connections support hundreds of bottles without compromising visual appeal.

3.2 Surface Treatment, Corrosion Resistance, and Durability

Surface quality directly affects appearance and longevity. We apply multiple layers of treatment to maintain finish and resist environmental wear:

-

Mechanical polishing or brushing to remove imperfections and create consistent texture.

-

Passivation to enhance corrosion resistance, particularly in humid or coastal locations.

-

Optional PVD or mirror finishes for luxury projects requiring reflective surfaces.

-

Scratch and impact testing to ensure durability under operational conditions.

By combining material choice, finish method, and protective treatments, our custom stainless wine storage solutions maintain structural and aesthetic quality for years, even under intensive use.

3.3 Inspection Process Before Shipment

Before any cabinet leaves the workshop, we conduct comprehensive inspections:

-

Dimensional verification against project drawings.

-

Weld and joint integrity assessment.

-

Surface finish and coating consistency check.

-

Functional tests for doors, lighting, and cooling components if included.

-

Packaging inspection to ensure safe transportation to the installation site.

This thorough pre-shipment process reduces installation issues and ensures clients receive units that meet both performance and visual expectations. For hybrid display and storage projects, stainless steel wine rack cabinets often undergo additional load testing to guarantee stability and alignment.

4. Commercial and Project-Based Supply Capabilities

Serving large-scale projects demands more than just manufacturing—it requires scalable production, precise logistics, and the ability to customize for various client needs. Our facilities are equipped to handle both high-volume orders and specialized project specifications, ensuring every cabinet meets commercial standards for durability, aesthetics, and functionality.

4.1 Stainless Steel Wine Cabinets for Hotels, Restaurants, and Bars

In hospitality settings, wine storage must balance visual appeal, accessibility, and reliability. For example, in a 5-star hotel wine bar, cabinets are integrated into the bar island, wall niches, and display units. Each installation considers customer flow, bottle visibility, and staff workflow.

Implementation steps include:

-

Conducting a site survey to measure spaces and identify traffic patterns.

-

Designing units to accommodate both display bottles and back-stock efficiently.

-

Coordinating with interior designers to match finishes, lighting, and materials.

-

Pre-assembling sections off-site when possible for faster installation.

In these scenarios, our custom stainless steel wine cabinets provide both durability and elegance, supporting hundreds of bottles while maintaining precise temperature and humidity control.

4.2 Bulk Production, OEM, and Private Label Manufacturing

For chains, restaurants, and hotel groups, we handle large-volume orders and OEM or private label projects. This involves:

-

Synchronizing production schedules to align with delivery timelines.

-

Standardizing modular components for repeatable quality and easier assembly.

-

Customizing branding elements, including logos, finishes, and internal layout.

-

Coordinating quality assurance checks at multiple production stages.

By combining modular design with quality oversight, we can produce hundreds of units simultaneously without compromising precision or finish. This approach ensures clients receive consistent products across multiple locations, a critical factor for large-scale deployments.

4.3 Lead Time, Production Capacity, and Export Packaging

Meeting project deadlines requires clear planning and efficient packaging. Our process includes:

-

Calculating production lead times based on order complexity and volume.

-

Scheduling parallel fabrication lines to maximize throughput.

-

Applying protective packaging materials, including foam inserts, corner guards, and reinforced crates.

-

Conducting final inspections to ensure every unit leaves the factory in pristine condition.

By combining robust production capacity with precise scheduling, we consistently deliver large orders on time, whether for domestic installation or international shipping. For multi-unit installations like hotel chains or commercial wine bars, our workflow ensures that every cabinet or rack arrives ready for seamless integration.

5. Ordering Process and Manufacturer Cooperation

Cooperating with a manufacturer effectively ensures that every custom wine cabinet project progresses smoothly from concept to installation. Clear communication, detailed technical documentation, and transparent pricing all contribute to successful partnerships. Our ordering process is designed to minimize errors, optimize production, and guarantee that clients receive exactly what they envisioned.

5.1 Design Confirmation and Technical Drawings

The first step in any order is aligning on design specifications. This includes:

-

Reviewing project requirements, including space constraints, bottle capacity, and layout preferences.

-

Preparing detailed technical drawings and 3D renderings for client approval.

-

Adjusting dimensions, finishes, and materials based on client feedback.

-

Finalizing plans for fabrication, ensuring every joint, panel, and shelf is accounted for.

By confirming designs upfront, we eliminate misunderstandings and reduce costly revisions during manufacturing. For high-end projects, stainless steel wine cabinets are often pre-visualized in mock-ups to validate both function and aesthetics in the actual space.

5.2 MOQ, Pricing Structure, and Cost Factors

Understanding minimum order quantities (MOQ) and cost drivers is essential for project budgeting. Factors influencing pricing include:

-

Material selection (304 vs 316 stainless steel, PVD or brushed finishes).

-

Cabinet size, layout complexity, and bottle capacity.

-

Additional features such as integrated cooling, lighting, or specialized racks.

-

Custom branding or OEM requirements for commercial clients.

By analyzing these elements, we provide transparent pricing and suggest cost-effective alternatives without compromising quality. For bulk or repeat orders, clients can benefit from scalable pricing structures and standardized components, ensuring both consistency and efficiency.

5.3 Logistics, Shipping Methods, and Global Delivery Support

Efficient delivery is critical for both domestic and international projects. Our workflow includes:

-

Selecting packaging materials to protect cabinets from scratches, dents, and humidity during transit.

-

Choosing shipping methods based on destination, size, and delivery urgency.

-

Coordinating customs documentation for international shipments.

-

Offering tracking and support to ensure timely delivery and installation readiness.

For projects requiring multiple units across various locations, our logistics team coordinates shipment batches and pre-assembly when possible, ensuring that large-scale orders arrive ready to install with minimal onsite adjustment. This approach is especially useful for hotel chains, restaurant groups, and wine bars requiring simultaneous deployment.

Partnering with a Stainless Steel Wine Cabinet Manufacturer like pvdstainlesssteel ensures that every unit, whether custom or standard, meets precise specifications, robust quality standards, and tailored design requirements. From in-house fabrication to multi-zone temperature control and durable surface finishes, working directly with a trusted brand guarantees both reliability and flexibility, letting you implement wine storage solutions that perfectly suit hotels, restaurants, bars, or private collections.