Decorative stainless steel panels in 2026 generally cost between $45 and $150 per square foot, depending on factors like thickness, surface finish, and customization. Residential installations lean toward the lower end, while commercial projects with perforations, engravings, or PVD coatings can reach premium pricing. Choosing the right combination of material and finish allows homeowners and businesses to achieve modern aesthetics without overpaying.

1. Buyer Background (Who Needs Decorative Stainless Steel Panels)

1.1 Residential Buyers

Homeowners looking to upgrade kitchens, bathrooms, or accent walls are increasingly opting for decorative stainless steel panels because of their durability, resistance to moisture, and sleek modern look. For example, in a recent urban renovation in New York, a homeowner replaced traditional tiles with stainless steel panels behind the kitchen counter, creating a reflective surface that is easy to clean while making the space feel larger. High-quality stainless panels not only enhance aesthetics but also increase property value.

1.2 Commercial Property Owners

Restaurants, hotels, and office buildings often select stainless steel panels for both functional and decorative purposes. Key reasons include:

-

Hygiene and Maintenance: Stainless steel surfaces resist stains and bacterial growth, making them ideal for kitchens and bathrooms.

-

Longevity: Unlike traditional wall claddings, stainless steel resists corrosion and scratches, reducing long-term maintenance costs.

-

Visual Appeal: Modern commercial interiors benefit from the reflective and clean appearance of these panels.

In a recent hotel lobby refurbishment in Chicago, designers installed a combination of SS Çelik Levha and glass elements, creating a premium yet practical surface that stands up to heavy foot traffic.

1.3 Industrial Buyers

Factories, laboratories, and cleanroom facilities require Paslanmaz Çelik Metal Plaka for walls, partitions, and equipment enclosures. These buyers prioritize specific grades, thicknesses, and surface finishes to meet safety and operational standards.

| Buyer Type | Common Panel Type | Typical Thickness | Key Considerations |

|---|---|---|---|

| yerleşim | Decorative stainless panels | 0,5–1,0 mm | Aesthetic, ease of cleaning |

| Reklam | SS Çelik Levha | 1,0–2,0 mm | Durability, hygiene, design impact |

| Industrial | Paslanmaz Çelik Metal Plaka | 1.5–3.0 mm | Strength, chemical resistance, compliance |

1.4 Architects and Interior Designers

Professionals specifying materials for clients often choose Metal Paslanmaz Çelik Sac for accent walls, ceiling cladding, or furniture in high-end projects. Their main goal is to combine functionality with design excellence. For example: in a luxury restaurant renovation in Los Angeles, designers used patterned stainless steel panels to create a feature wall behind the bar, pairing it with LED lighting to highlight textures and finishes.

1.5 Contractors and Renovation Experts

Contractors who manage installation projects need Paslanmaz Çelik Sac in bulk and appreciate suppliers who can provide consistent quality, fast delivery, and precise specifications. Steps contractors follow when selecting panels include:

-

Assess project size and panel coverage needed.

-

Verify panel thickness, finish, and grade.

-

Compare supplier prices, delivery time, and after-sales support.

-

Plan installation sequencing to minimize on-site handling and scratches.

By understanding these buyer backgrounds, manufacturers and suppliers can tailor product offerings and pricing structures to meet the specific needs of each segment.

2. Average Market Prices in 2026

2.1 Residential Project Pricing

For homeowners planning kitchen backsplashes, bathroom walls, or accent features, decorative stainless steel panels cost in 2026 generally ranges from $45 to $120 per square foot, depending on material grade, surface finish, and customization. Premium finishes like brushed or patterned surfaces often add 15–25% to the base price.

Factors affecting residential pricing include:

-

Panel Thickness: Standard 0.5–1.0 mm panels are more affordable, while thicker panels increase cost and durability.

-

Surface Treatment: Brushed, mirror, or patterned finishes require additional processing, adding to labor and material costs.

-

Installation Complexity: If panels require cutting around fixtures, corners, or custom edges, contractors may charge an extra $10–$20 per square foot for precision work.

For example, a mid-sized urban apartment in Boston used high-quality stainless panels for a 50-square-foot kitchen backsplash. The total material cost was around $3,000, while installation added approximately $800, resulting in a comprehensive $76 per square foot project cost. These figures help homeowners plan budgets accurately while choosing the right finish and thickness.

2.2 Commercial Project Pricing

In commercial settings like restaurants, hotels, or office interiors, prices are influenced by both material specifications and volume. Stainless steel panels for commercial use range from $60 to $150 per square foot depending on grade, corrosion resistance, and decorative treatments.

Key pricing determinants include:

-

Panel Size and Layout: Large-format panels reduce visible seams but cost more due to handling and shipping.

-

Durability Requirements: High-traffic areas may require 1.0–2.0 mm thickness or anti-scratch coatings.

-

Installation and Labor: Contractors may follow a multi-step process:

-

Surface preparation and leveling.

-

Precise measurement and cutting of panels.

-

Mounting with adhesive and mechanical fasteners.

-

Sealing edges to prevent moisture penetration.

-

A restaurant renovation in Los Angeles installed decorative stainless steel panels across 200 square feet of kitchen and dining walls. Material cost totaled $18,000, and installation labor added another $5,500, giving an average $118 per square foot cost. Choosing the right panel grade and finish can significantly affect both aesthetics and long-term maintenance costs.

2.3 Bulk Order and Wholesale Pricing

For contractors and suppliers purchasing in bulk, prices per square foot decrease significantly due to economies of scale. Wholesale rates for high-volume orders in 2026 are approximately:

| Order Volume | Typical Cost per Sq Ft | Notes |

|---|---|---|

| 500–1,000 sq ft | $40–$55 | Standard finishes, single grade |

| 1,000–5,000 sq ft | $35–$50 | Mix of finishes, minor customizations |

| 5,000+ sq ft | $30–$45 | Large-scale projects, standard delivery |

Practical steps for bulk buyers:

-

Confirm panel grade and thickness with supplier specifications.

-

Verify shipping logistics and handling procedures to prevent scratches or dents.

-

Evaluate available finishes and color coatings to match project requirements.

-

Schedule phased delivery if installation occurs over multiple weeks.

Bulk buyers often save 10–30% per square foot compared to retail pricing, depending on volume, finish, and shipping arrangements. This strategy allows contractors and large-scale projects to maintain consistent quality while controlling budgets effectively.

3. Installation and Labor Costs

3.1 Labor Rates by Region

Labor costs for installing decorative stainless steel panels vary significantly depending on geographic location and local contractor rates. In 2026, typical installation rates per square foot are:

-

North America: $15–$25 per sq ft for standard panels, higher-end finishes may reach $30.

-

Europe: €12–€22 per sq ft, with urban centers like London and Paris leaning toward the upper range.

-

Asia-Pacific: $10–$18 per sq ft in cities such as Singapore or Sydney; remote locations may add transport surcharges.

Factors influencing labor costs include:

-

Local wage standards and union agreements.

-

Regional availability of skilled installers familiar with stainless steel.

-

Complexity of the installation site, such as multi-story or tight-access areas.

For instance, a mid-rise apartment in Toronto used high-quality stainless panels for the lobby walls. Labor alone accounted for approximately $5,200 for 180 sq ft, reflecting both the panel complexity and skilled workforce rates.

3.2 Installation Complexity and Time

The complexity of installing stainless steel panels directly impacts both labor cost and project timeline. Key considerations include:

-

Site Preparation: Ensure walls are level, clean, and free from moisture. Uneven surfaces require additional leveling work, which can add 10–15% to labor time.

-

Panel Cutting and Shaping: Customized edges, curves, or insets for fixtures increase installation time. Typically, cutting and shaping adds 0.5–1 hour per panel.

-

Mounting and Fastening: Panels are either mechanically fastened or adhered with industrial-grade adhesives. Using both methods ensures stability but extends installation by 20–30%.

-

Finishing Touches: Sealing seams, polishing edges, and cleaning the surface to remove fingerprints and dust adds 1–2 hours per 100 sq ft.

A commercial kitchen renovation in Chicago installed stainless steel wall panels over 250 sq ft. The project required 4 installers working 2 full days, including cutting around plumbing fixtures and sealing seams, emphasizing that complexity directly affects costs.

3.3 Additional Accessories or Mounting Costs

Beyond labor, additional components can impact total project expenditure. These include:

-

Edge Trims and Corner Guards: Aluminum or stainless steel trims cost $5–$12 per linear foot but improve durability and aesthetics.

-

Mounting Hardware: Screws, brackets, and adhesive can add $2–$5 per sq ft, depending on panel size and substrate type.

-

Protective Films and Sealants: Temporary protective films prevent scratches during installation, while sealants prevent moisture infiltration. Combined, they add approximately $1–$3 per sq ft.

Step-by-step cost management for contractors:

-

Calculate total panel area and determine accessory requirements.

-

Select mounting method—mechanical, adhesive, or hybrid—based on wall substrate.

-

Order trims and protective materials to match panel dimensions.

-

Schedule installation sequence to minimize handling and avoid damage.

-

Inspect all panels after mounting to ensure alignment and surface quality.

By accounting for these accessory and mounting costs early, contractors can avoid budget overruns while maintaining high-quality results. Proper planning also ensures a clean, durable, and visually appealing finish that maximizes the value of decorative stainless panels.

4. Customization and Special Features Costs

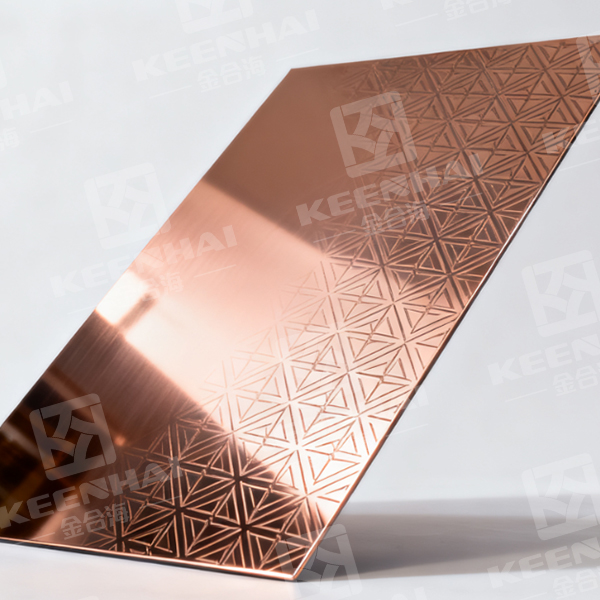

4.1 Engraving, Patterns, and Perforations

Custom decorative touches like engraving, patterned embossing, or perforations significantly influence the total cost of decorative stainless steel panels. These features enhance visual appeal but require specialized machinery and skilled labor.

Key factors affecting cost:

-

Engraving Depth and Detail: Simple linear designs add $5–$10 per sq ft, while intricate patterns with depth can reach $15–$25 per sq ft.

-

Perforation Size and Density: Higher perforation density improves airflow and design complexity but increases manufacturing time and material waste, raising costs by 10–20%.

-

Panel Size and Shape: Larger or irregular panels require more precise cutting and alignment, which can add 1–2 hours of labor per panel.

In a boutique hotel renovation in Miami, designers used perforated SS Çelik Levha for ceiling panels above the lounge area. The custom pattern required 15 panels at 1.2 mm thickness, costing $3,200 in materials Ve $850 for installation, highlighting how intricate designs impact budgets.

4.2 Color and PVD Coating Options

Color customization through PVD coating or other finishing processes transforms standard stainless panels into statement pieces. Costs depend on coating type, panel size, and finish complexity.

Pricing considerations include:

-

PVD Coating: Gold, bronze, or black coatings generally add $20–$35 per sq ft due to vacuum deposition processes.

-

Powder Coating or Painted Finishes: More economical options, typically $10–$18 per sq ft, suitable for both residential and commercial projects.

-

Durability Requirements: High-traffic areas require scratch-resistant coatings, which may add 5–10% to the base cost.

Step-by-step selection process:

-

Determine desired aesthetic and color scheme.

-

Confirm panel thickness and substrate compatibility with the chosen coating.

-

Choose finish type: matte, brushed, mirror, or patterned.

-

Order test samples to verify color consistency under site lighting.

-

Schedule coating application prior to installation for optimal adhesion and quality.

A modern office reception in Berlin featured Metal Paslanmaz Çelik Sac with black PVD coating. Panels measured 120 sq ft total, costing $4,000 for materials Ve $1,000 for labor, demonstrating how coatings enhance visual impact while influencing budget.

4.3 Integration with Other Materials

Decorative stainless panels often combine with glass, wood, or stone to create unique interior features. This integration affects both material and labor costs due to specialized cutting, alignment, and support requirements.

Practical steps for integration:

-

Assess panel and secondary material dimensions for seamless alignment.

-

Determine appropriate fasteners or adhesives to maintain structural integrity.

-

Plan installation sequence to prevent scratches or damage to either material.

-

Use spacers, clamps, or supports to achieve precise alignment during mounting.

-

Conduct final inspection for visual consistency and durability.

Integrating stainless steel with other materials can add $10–$25 per sq ft depending on complexity. For instance, a restaurant in Tokyo combined stainless steel sheets with backlit glass panels for the bar wall. The combined effect increased overall project cost by approximately 20%, but the visual payoff was substantial and highly valued by clients.

5. Cost Comparison and Budgeting Tips

5.1 Comparing Standard vs Premium Panels

When planning a project, understanding the difference between standard decorative stainless steel panels and premium options is crucial. Standard panels usually use 0.5–1.0 mm thickness with basic brushed or mirror finishes, costing $45–$75 per sq ft, whereas premium panels include features like engraving, perforation, or PVD coating, with thickness up to 2.0 mm, costing $90–$150 per sq ft.

Comparison Table:

| Özellik | Standard Panels | Premium Panels |

|---|---|---|

| Thickness | 0,5–1,0 mm | 1,0–2,0 mm |

| Yüzey Kaplaması | Brushed, Mirror | Custom patterns, PVD coating, High-end textures |

| Dayanıklılık | Good for light use | High resistance to scratches and corrosion |

| Installation Complexity | Moderate | Requires skilled labor and precise alignment |

| Typical Price | $45–$75 / sq ft | $90–$150 / sq ft |

A hotel lobby renovation in Los Angeles opted for decorative stainless steel panels with custom perforations. Though premium panels doubled material costs compared to standard options, they provided a distinctive, durable finish that increased perceived value and client satisfaction.

5.2 Estimating Total Project Cost

Calculating the full budget involves more than material prices. Key steps include:

-

Measure total panel area precisely, including walls, ceilings, or accent surfaces.

-

Select panel type (standard vs premium) and factor in thickness, surface treatment, and finish.

-

Add labor costs based on region and installation complexity.

-

Include accessory costs such as trims, corner guards, and protective sealants.

-

Account for customizations, like engraving, perforation, or PVD coating.

Example Calculation:

-

Residential kitchen backsplash: 50 sq ft

-

Premium stainless steel panels: $100 per sq ft → $5,000

-

Labor and installation: $18 per sq ft → $900

-

Accessories and trims: $2 per sq ft → $100

Total Estimated Cost: $6,000 → $120 per sq ft

This detailed approach ensures homeowners and contractors avoid surprises and make informed decisions.

5.3 Ways to Optimize Costs Without Compromising Quality

Budget-conscious buyers can reduce expenses while maintaining performance and aesthetics. Strategies include:

-

Bulk Ordering: Purchase panels in larger quantities to reduce per-square-foot costs.

-

Selective Customization: Apply PVD coating or perforation only on focal areas rather than the entire surface.

-

Simplify Installation: Pre-cut panels in the factory to reduce on-site labor and potential waste.

-

Use Standard Sizes Where Possible: Custom sizes increase both fabrication and installation costs.

-

Partner with Reliable Suppliers: Working with experienced vendors like stainless steel sheets ensures consistent quality, reducing errors and rework costs.

A restaurant renovation in Chicago combined standard panels for side walls and premium panels for the bar feature wall. This approach reduced total costs by approximately 25%, while preserving visual impact in key areas.