High-quality Inox can be spotted through meticulous surface and finish inspection. Look for smooth, uniform surfaces without scratches, pitting, or discoloration. Distinguish between brushed, mirror, or polished finishes, as the finish directly influences corrosion resistance and maintenance requirements. For example, premium stainless panels used in modern architectural facades maintain their sheen even under harsh environmental exposure, indicating superior quality.

1. Visual Inspection of Surface and Finish

Visual inspection is the first and most crucial step in evaluating the quality of Inox material. High-quality stainless steel surfaces immediately reveal the manufacturing precision and durability. Professionals often examine panels under bright lighting to detect irregularities, reflections, or defects that can affect both appearance and long-term performance. Many architects prefer high-grade stainless steel sheets for visible applications such as building facades, kitchen panels, and elevator interiors because smoothness and finish directly impact the final look.

1.1 Checking for Smoothness and Uniformity

The surface of premium Inox should feel consistently smooth, without bumps, ridges, or rough patches. Smoothness indicates proper rolling and finishing processes, which play a key role in corrosion resistance.

To check for uniformity:

-

Run your hand along the panel to feel for inconsistencies.

-

Hold a light at a shallow angle; uneven reflections highlight surface waviness.

-

Compare multiple panels side by side to ensure consistent thickness and texture.

In modern commercial projects, such as hotel lobbies or high-end kitchens, uniform panels not only enhance aesthetics but also simplify installation, reducing alignment issues. For exterior applications requiring металл дат басмас корычтан, professionals often select металл дат басмас корычтан that are precision-rolled and polished to strict tolerances.

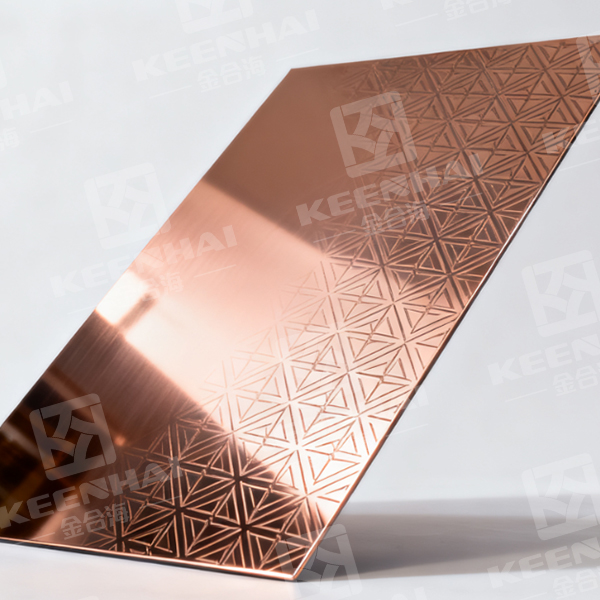

1.2 Identifying Polished, Brushed, or Mirror Finishes

Inox materials come in various finishes, each serving functional and decorative purposes:

-

Polished finish: Reflective but less intense than mirror; used in interior panels and trims.

-

Brushed finish: Subtle linear texture; hides fingerprints and minor scratches; popular in kitchens and elevators.

-

Mirror finish: High-gloss reflective surface; ideal for premium design applications.

Distinguishing these finishes requires both visual and tactile inspection. Reflections reveal surface type, while lightly running a finger across the material highlights fine textures or directional brushing. Choosing the correct finish affects cleaning, wear resistance, and visual consistency across multiple panels in commercial and residential applications.

1.3 Detecting Surface Defects, Scratches, or Pitting

Even small surface imperfections can indicate inferior quality or improper finishing. Defects like scratches, pitting, or micro-cracks compromise both appearance and corrosion resistance.

Key inspection steps:

-

Examine under angled, bright light to spot shallow scratches or dents.

-

Carefully inspect edges and corners where flaws often appear.

-

Use magnification for pitting, especially in high-grade panels for food, medical, or exterior applications.

In practice, SS steel plates used in demanding environments show minimal surface defects before any cleaning or polishing. Panels failing visual inspection are typically rejected, since minor flaws can expand into corrosion issues over time.

2. Material Composition and Grade Verification

Understanding the composition and grade of Inox is essential to ensure the material meets performance and durability requirements. High-quality stainless steel relies on precise alloying, and even small deviations in chromium, nickel, or molybdenum can significantly affect corrosion resistance, strength, and hardness. Accurate grade verification prevents costly mistakes in construction, industrial, and consumer applications.

2.1 Understanding Austenitic, Ferritic, and Martensitic Grades

Inox materials are categorized into three main types, each with unique characteristics:

-

Austenitic grades (e.g., 304, 316) are the most common, offering excellent corrosion resistance, superior toughness, and non-magnetic properties. These grades are often used for stainless steel metal plates in kitchens, medical equipment, and architectural panels.

-

Ferritic grades contain higher chromium and lower nickel, providing good resistance to stress corrosion cracking and magnetic properties, suitable for automotive trims or decorative cladding.

-

Martensitic grades are heat-treatable, featuring high hardness and moderate corrosion resistance, often applied in cutlery, surgical instruments, and heavy-duty industrial tools.

To quickly identify the category: check the alloy composition and perform a simple magnet test—ferritic and martensitic types attract magnets, while austenitic generally does not.

2.2 Reading Grade Numbers and Alloy Codes

Every high-quality Inox material carries a grade number, typically defined by international standards such as AISI or EN. Understanding these codes allows you to verify mechanical properties, corrosion resistance, and suitability for your project.

Steps for proper verification:

-

Locate the stamped grade number or manufacturer’s alloy code.

-

Cross-reference the code with official alloy tables to determine chromium, nickel, and molybdenum percentages.

-

For critical applications, consider confirming the grade using spectrographic analysis or chemical testing.

Example of grade identification table for common austenitic stainless steels:

| Grade | Chromium (%) | Nickel (%) | Molybdenum (%) | Key Feature |

|---|---|---|---|---|

| 304 | 18–20 | 8–10 | 0 | Excellent corrosion resistance, widely used in kitchens |

| 316 | 16–18 | 10–14 | 2–3 | Superior resistance to chlorides, ideal for marine environments |

This table provides a clear reference for selecting the right Inox material based on alloy composition and environmental requirements.

2.3 Confirming Chromium, Nickel, and Molybdenum Content

The three primary alloying elements—chromium, nickel, and molybdenum—determine the performance of Inox materials. Chromium forms a passive oxide layer that prevents rust, nickel improves ductility and toughness, and molybdenum enhances resistance to pitting and localized corrosion.

Verification steps in practice:

-

Use handheld XRF analyzers to quickly measure elemental percentages.

-

Compare results against the specified grade standards to ensure compliance.

-

In production or architectural settings, verify multiple batches to maintain uniform quality, especially for SS steel plates intended for high-visibility installations.

Consistently confirming alloy content avoids future failures and ensures the Inox material will perform reliably under expected conditions, whether for structural, decorative, or industrial applications.

3. Mechanical and Physical Properties Testing

Testing the mechanical and physical properties of Inox materials ensures that they meet both structural and functional requirements. Even minor variations in hardness, ductility, or magnetic response can affect performance in industrial, architectural, or consumer applications. Proper testing prevents material failure and guarantees consistent quality.

3.1 Assessing Hardness and Strength

Hardness and tensile strength are critical indicators of how Inox will perform under stress. Common methods include:

-

Rockwell hardness testing – measures resistance to permanent indentation and provides a precise hardness number.

-

Tensile testing – stretches a sample until it breaks, recording yield strength, ultimate tensile strength, and elongation.

-

Impact testing – evaluates toughness, especially for austenitic or martensitic grades.

Example reference values for commonly used austenitic steel sheets:

| Grade | Hardness (HRB) | Tensile Strength (MPa) | Yield Strength (MPa) |

|---|---|---|---|

| 304 | 70–90 | 520–720 | 210–275 |

| 316 | 85–95 | 550–750 | 220–290 |

For high-visibility architectural panels, selecting materials like premium stainless steel sheets ensures both aesthetic appeal and reliable strength.

3.2 Testing Magnetic Properties

Magnetic testing is a fast and non-destructive way to differentiate austenitic, ferritic, and martensitic Inox grades.

-

Austenitic types (304, 316) are mostly non-magnetic in the annealed state but may show slight magnetism after cold working.

-

Ferritic and martensitic grades display strong magnetic properties.

Step-by-step magnetic testing process:

-

Clean the sample surface to remove oils or coatings.

-

Use a handheld magnet to check attraction strength.

-

Record results to confirm material classification.

This method is particularly useful in large-scale projects where quick verification of premium stainless panels is necessary for quality control.

3.3 Evaluating Ductility and Flexibility

Ductility and flexibility testing reveals how well Inox can withstand bending, forming, or shaping without cracking. Key testing approaches include:

-

Bend tests – measure the angle a sample can be bent before failure.

-

Forming tests – simulate stamping or rolling processes to ensure the material maintains integrity.

-

Elongation measurement – checks how much the material stretches under tensile stress.

For example, high-quality stainless steel metal plates used in kitchen equipment or handrails require both high ductility and consistent flexibility to meet practical performance standards. Proper testing ensures that material will perform reliably in real-world installations, preventing deformation or breakage during use.

4. Corrosion Resistance and Oxidation Tests

Testing corrosion resistance is crucial to ensure that Inox materials maintain their structural integrity and aesthetic appearance over time, especially in humid, coastal, or industrial environments. High-quality testing reveals not only how materials resist oxidation but also how they perform when exposed to chemicals, salt spray, or prolonged moisture.

4.1 Exposure to Moisture or Salt Spray Simulation

Salt spray tests simulate aggressive conditions such as marine environments or industrial pollution. Key steps include:

-

Prepare samples by cleaning and drying all surfaces to remove oils and contaminants.

-

Place samples in a salt fog chamber with a 5% NaCl solution at 35°C for a defined duration, typically 24–96 hours depending on grade.

-

Monitor corrosion onset, including pitting, rust spots, or discoloration.

Grades like 316 and 304 stainless steels demonstrate different resistance levels. Premium stainless panels often withstand prolonged exposure without visible deterioration, making them ideal for exterior cladding or coastal constructions.

4.2 Evaluating Resistance to Stains, Rust, and Discoloration

Beyond moisture, Inox materials must resist common staining agents such as acids, oils, and cleaning chemicals. Testing involves:

-

Chemical immersion tests: Submerge samples in acidic or alkaline solutions and check for color change or surface damage.

-

Repeated cleaning simulations: Rub surfaces with abrasives or detergents to ensure that the finish and corrosion resistance remain intact.

Observation metrics include surface gloss retention, absence of pitting, and uniform color maintenance. Using high-quality steel sheets in kitchens or food-processing areas ensures materials remain hygienic and visually consistent over years of use.

4.3 Comparing Behavior of Different Grades Under Harsh Conditions

Different Inox grades behave differently under extreme conditions. A concise comparison can guide material selection:

| Grade | Salt Spray Resistance (hrs) | Rust Onset | Surface Discoloration |

|---|---|---|---|

| 304 | 72–96 | Minimal | Slight possible |

| 316 | 168+ | Negligible | None |

| 430 | 24–48 | Noticeable | Possible |

This table highlights why selecting the correct grade is crucial for long-term durability. For instance, stainless steel metal plates used in outdoor architectural applications must resist corrosion without frequent maintenance, whereas lower grades may require protective coatings or periodic replacement.

5. Certification, Manufacturing, and Supplier Verification

Ensuring that Inox material is genuine, high-quality, and traceable requires careful verification of both documentation and supplier practices. Reliable certification and clear traceability not only guarantee performance but also protect against substandard or counterfeit materials.

5.1 Checking for Material Certifications and Mill Test Reports

Material certifications and mill test reports (MTRs) provide verified details about chemical composition, mechanical properties, and compliance with international standards such as ASTM, EN, or ISO. Key steps include:

-

Request MTRs for each batch to verify chromium, nickel, and molybdenum percentages.

-

Cross-check grade numbers with documented standards to ensure the steel matches specifications.

-

Confirm traceability codes on the certificate match the physical material for accountability.

High-quality suppliers often provide premium stainless panels that come with full documentation, allowing architects and engineers to confidently specify them for structural, food-processing, or medical applications.

5.2 Assessing Manufacturer Reputation and Quality Control Processes

Supplier reliability directly impacts material performance. Important checks include:

-

Factory audits to evaluate production consistency and finishing accuracy.

-

Quality control logs showing inspection of surface finish, thickness, and mechanical properties.

-

Historical track record for delivering materials that withstand harsh environments without corrosion or discoloration.

A trusted stainless steel metal plate manufacturer implements rigorous QC processes, ensuring each batch meets both visual and mechanical standards, which reduces risk in critical architectural or industrial projects.

5.3 Inspecting Packaging, Labeling, and Traceability

Proper handling and labeling prevent damage and misidentification:

-

Inspect packaging for protective layers that prevent scratches or moisture ingress.

-

Verify labels for grade, batch number, thickness, and dimensions.

-

Confirm traceability from supplier certificate to delivered product, including any heat treatment or surface finish notes.

Materials like SS Steel Plates with clear traceability allow construction teams to track origin, confirm authenticity, and maintain project compliance with both regulatory and design specifications.

Spotting high-quality Inox material requires a combination of keen observation, precise testing, and careful supplier verification. By systematically checking surface finish, verifying mechanical and chemical properties, and confirming certifications and traceability, you ensure that the steel you choose will perform reliably under demanding conditions. High-quality Inox is not just a material—it’s a commitment to durability, aesthetic appeal, and long-term value for architectural, industrial, or consumer applications.