PVD stainless steel sheets are chosen for luxury retail because they maintain a high-gloss, scratch-resistant finish that preserves the look of premium displays. Their consistent quality and customizable finishes ensure that every store reflects the brand's sophisticated identity, creating a visually striking environment that customers instantly recognize and trust.

1. Visual Appeal and Aesthetic Flexibility

PVD stainless steel sheets bring unmatched aesthetic versatility, making them a top choice for luxury retail interiors. Their reflective surfaces, wide range of colors, and compatibility with custom finishes allow designers to create high-end, eye-catching installations that enhance customer perception. For projects emphasizing brand prestige, choosing premium stainless steel sheet material is essential to achieve both durability and elegance.

1.1 High-Gloss Mirror Finishes for Luxury Displays

High-gloss mirror finishes create a polished, premium look, reflecting both lighting and surrounding decor to make retail spaces appear larger and more inviting. Key points when specifying mirror finishes include:

-

Surface flatness: Ensure the sheet has a flatness tolerance within 0.5 mm per 2 meters to avoid visual distortion.

-

Scratch resistance: Opt for sheets with protective films during transport to maintain pristine surfaces.

-

Consistency across panels: For large displays, inspect multiple panels side by side to guarantee uniform reflectivity.

In high-end jewelry showrooms, mirror-finished panels installed along display walls enhanced the perception of luxury while providing durable protection against daily handling. This finish is often available as Металева пластина з нержавіючої сталі or Металевий лист з нержавіючої сталі, offering flexibility depending on panel size and installation requirements.

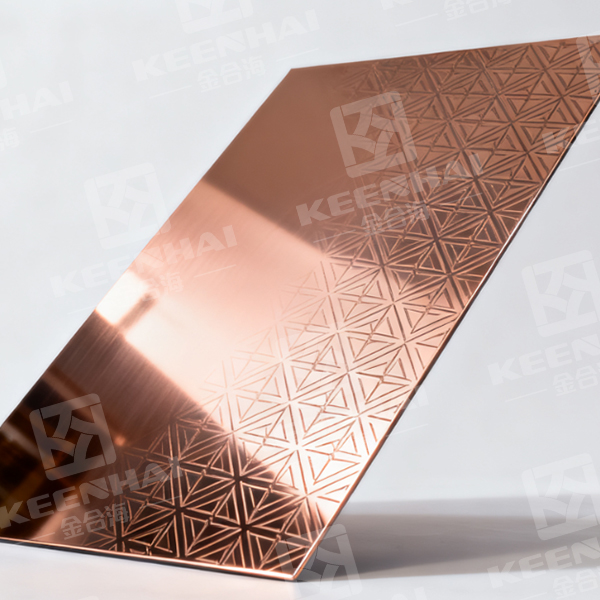

1.2 Customized Colors and PVD Coating Options

PVD coating allows designers to select from a spectrum of colors such as gold, black, rose gold, and bronze. Color customization factors to evaluate include:

| Color Finish | Reflectivity | Scratch Resistance | Типовий випадок використання |

|---|---|---|---|

| Gold | Високий | Середній | Accent walls, luxury display cases |

| Black | Середній | Високий | Modern retail interiors, fixtures |

| Rose Gold | Середній | Середній | Boutique stores, jewelry showcases |

| Bronze | Низький | Високий | Furniture panels, decorative elements |

-

Check coating adhesion using a cross-hatch adhesion test to ensure longevity.

-

Verify color consistency across multiple batches to prevent noticeable variation on large installations.

-

Combine colors strategically with lighting to highlight displays and create immersive brand experiences.

These options work seamlessly with Листова нержавіюча сталь or stainless steel sheet panels, allowing designers to balance aesthetic appeal with functional durability.

1.3 Integration with Lighting and Interior Design

The reflective and colored surfaces of PVD stainless steel sheets enhance interior design in multiple ways:

-

Ambient lighting reflection: High-gloss finishes bounce light throughout the space, reducing the need for excessive fixtures.

-

Directional accent lighting: Spotlights can be placed strategically to emphasize display items while mirrored surfaces diffuse light naturally.

-

Complementing materials: PVD panels pair well with wood, glass, and stone, providing a balanced luxury aesthetic.

-

Customization for built-in fixtures: Panels can be cut and fabricated to fit wall claddings, shelving, or display units without compromising finish quality.

In a luxury boutique project, integrating rose gold PVD panels with LED backlighting resulted in enhanced brand ambiance and visually striking retail interiors, proving that material selection directly impacts perceived quality and customer engagement.

2. Durability and Long-Term Performance

PVD stainless steel sheets are designed for high-traffic luxury environments, offering superior resistance to corrosion, scratches, and wear compared to traditional metals. Choosing PVD stainless steel sheets ensures that surfaces maintain their premium appearance over years of continuous use, even under heavy handling in retail spaces or public areas. Their long-term performance significantly reduces maintenance frequency and replacement costs.

2.1 Corrosion and Scratch Resistance in High-Traffic Areas

Corrosion resistance is critical for panels exposed to moisture, cleaning chemicals, or human contact. Key considerations include:

-

Material grade selection: Use 304 or 316 variants for areas prone to humidity or cleaning liquids.

-

Surface protection: Apply anti-fingerprint coatings to prevent visible streaks and reduce daily cleaning needs.

-

Scratch resistance testing: Perform pencil hardness or abrasion tests to ensure coatings withstand frequent contact with sharp objects or display setups.

For example, retail counters and elevator cladding often experience continuous contact, and panels with proper PVD finishes demonstrate minimal visible wear over 3–5 years. The same principles apply whether using stainless steel panels, металеві листи з нержавіючої сталі, або steel sheet stainless for decorative fixtures.

2.2 Wear-Resistant Surface Treatments

Beyond base corrosion resistance, additional treatments enhance durability and longevity:

| Surface Treatment | Key Benefits | Typical Application |

|---|---|---|

| Anti-Fingerprint Coating | Reduces cleaning frequency, maintains shine | Elevator panels, touch surfaces |

| Hard PVD Layer | Increases scratch and abrasion resistance | Countertops, retail display edges |

| Protective Films | Protects during transport and installation | Large wall panels, mirrored surfaces |

-

Inspect panels for uniform coating thickness, ideally 2–5 microns for decorative finishes.

-

Confirm that hard layers bond fully to the base metal to prevent flaking or peeling.

-

Use protective films until installation is complete to safeguard against transport or handling damage.

These enhancements ensure PVD panels endure daily operations without losing their visual appeal, critical in high-end retail or hospitality environments.

2.3 Longevity Compared to Traditional Materials

When comparing PVD stainless steel sheets to standard aluminum, wood, or painted steel panels, the advantages become evident:

-

Extended lifespan: PVD stainless steel maintains structural integrity and finish quality for over 10 years under normal indoor use.

-

Reduced maintenance: Unlike painted metals or laminated wood, surfaces do not require frequent refinishing or protective sealants.

-

Consistent aesthetic: Even after repeated cleaning or exposure to light and humidity, the color and reflectivity remain stable, making it ideal for high-visibility installations.

For luxury retail stores, hotels, and public interiors, investing in PVD-treated sheets provides measurable long-term value, combining elegance with functional durability. Choosing the right variant from reliable suppliers further ensures that performance standards meet design expectations.

3. Ease of Fabrication and Installation

PVD stainless steel sheets are engineered for precision, making them exceptionally easy to work with during both fabrication and installation. Their consistent thickness and uniform surface coatings allow fabricators to achieve clean cuts, sharp edges, and flawless panel alignment, reducing labor time and minimizing material waste. Whether used for luxury retail displays, modular partitions, or decorative cladding, these sheets streamline project workflows while maintaining high aesthetic standards.

3.1 Precision Cutting and Edge Finishing

Accurate fabrication is essential to retain the visual appeal of PVD-treated surfaces. Steps to ensure precise cuts include:

-

Measure twice, cut once: Use calibrated laser or CNC cutting tools for repeatable accuracy.

-

Edge smoothing: Employ deburring tools or precision rollers to eliminate sharp edges while preserving surface integrity.

-

Surface protection: Apply temporary protective films during handling to prevent scratches or fingerprints.

High-end retail counters and elevator cladding often require tight tolerances of ±0.2 mm, which PVD stainless steel consistently meets. This level of precision ensures panels fit perfectly into pre-designed modular systems without additional adjustments.

3.2 Compatibility with Modular Retail Fixtures

PVD stainless steel panels integrate seamlessly with modular display systems, reducing installation complexity:

-

Standardized panel sizes align with pre-fabricated frame structures.

-

Panels can be easily fastened using clips, brackets, or concealed mounts without compromising surface finishes.

-

Modular compatibility allows quick replacements or updates, particularly in fast-changing retail layouts.

Using panels like these simplifies large-scale installations, whether for wall cladding, display shelving, or decorative column wraps, ensuring consistency across multiple units and locations.

3.3 Simplified Maintenance and Cleaning Processes

Ease of maintenance is a key advantage of PVD finishes in high-traffic areas:

-

Routine cleaning: Use soft microfiber cloths with neutral pH cleaners to remove fingerprints and dust.

-

Stain prevention: Apply anti-fingerprint or protective coatings to high-contact surfaces, extending intervals between deep cleaning.

-

Quick inspection: Regular visual checks allow early detection of scratches or edge wear before they affect the overall look.

Compared to painted metals or laminates, these sheets retain their shine and color for years with minimal effort, making them ideal for luxury retail spaces where presentation quality is critical.

4. Cost Efficiency and Value for High-End Projects

Investing in PVD stainless steel sheets provides measurable long-term value for luxury projects. Their durability, low maintenance requirements, and consistent quality translate into cost savings over the lifecycle of installations. High-end retail stores, luxury hotels, and upscale office interiors benefit from reduced upkeep, fewer replacements, and easier integration with standardized modular systems, making the upfront investment highly justifiable.

4.1 Long-Term Savings Through Reduced Maintenance

The protective coatings on these sheets reduce the frequency of cleaning and surface refinishing, delivering tangible savings over time:

-

Routine cleaning with mild detergents and microfiber cloths takes minimal time, often less than 10 minutes per panel.

-

Anti-fingerprint and scratch-resistant finishes prevent visible wear in high-contact areas, lowering maintenance labor costs by up to 40% compared to painted metals or laminates.

-

Durable coatings extend the lifespan of panels, reducing the need for costly refurbishments in premium retail displays.

This combination of low maintenance effort and extended longevity ensures that PVD stainless steel remains cost-effective even for large-scale installations.

4.2 Bulk Supply Options and Standardized Sheet Sizes

Sourcing panels in bulk and using standardized dimensions can further enhance cost efficiency:

-

Standard sheet sizes (e.g., 1220 x 2440 mm or 48 x 96 inches) minimize material waste during fabrication.

-

Ordering large quantities directly from manufacturers reduces per-unit costs due to economies of scale.

-

Coordinated shipments and consolidated logistics lower transportation fees, especially for projects spanning multiple locations.

For instance, retail chains often opt for pre-cut, uniform panels to simplify installation and reduce on-site labor, which accelerates project timelines while controlling budget.

4.3 Minimizing Replacement Costs Through Durability

Durability is a key factor in reducing replacement expenses over time:

-

PVD stainless steel surfaces resist corrosion, scratches, and fading under daily use, extending replacement cycles to 10+ years.

-

High-impact areas such as elevator interiors, store counters, and decorative wall cladding withstand frequent contact without losing structural integrity.

-

When replacements are eventually required, panels are modular and standardized, making swaps quick and cost-efficient, avoiding complex retrofits.

By combining long-lasting materials with modular design principles, luxury projects maintain premium aesthetics without incurring continuous high costs.

5. Brand Consistency and Customer Experience

Using high-quality PVD stainless steel sheets in retail and hospitality spaces ensures that every touchpoint aligns with a brand’s premium identity. These sheets not only deliver a luxurious look but also offer repeatable quality across different locations, enhancing customer perception and reinforcing brand value. Consistent finishes, modular installation, and customizable PVD coatings allow brands to maintain a uniform aesthetic while meeting the practical demands of high-traffic areas.

5.1 Enhancing Store Identity with Premium Finishes

-

Applying mirror, hairline, or etched finishes creates a sophisticated ambiance that immediately communicates luxury.

-

Premium PVD coatings provide subtle variations in color and texture, allowing designers to highlight brand-specific design cues.

-

High-contact surfaces such as checkout counters, display fixtures, and elevator panels maintain a polished look even under frequent use, reinforcing a consistent brand experience for visitors.

By leveraging the natural shine and tactile quality of stainless steel surfaces, stores convey both quality and durability that reflect brand values.

5.2 Consistent Appearance Across Multiple Locations

-

Standardized sheet sizes and pre-finished panels ensure that each outlet mirrors the flagship store’s aesthetic.

-

Color-matched PVD coatings allow precise replication of the same finish, avoiding visible differences between locations.

-

Modular panels simplify installation and future upgrades, guaranteeing that brand visuals remain uniform, whether in urban malls or standalone boutique stores.

For retail chains, this consistency strengthens customer trust and recognition, making every visit feel like an extension of the same high-end experience.

5.3 Aligning Material Choice with Luxury Branding

-

Material selection directly influences perceived quality; opting for Вироби з нержавіючої сталі з PVD-покриттям conveys sophistication and longevity.

-

Combining functional performance (durability, corrosion resistance) with aesthetic appeal ensures that materials complement the brand story.

-

Long-lasting finishes reduce the need for frequent replacements, keeping spaces pristine and reinforcing a commitment to premium quality.

Integrating these materials thoughtfully supports the luxury narrative, showing customers that attention to detail matters in every aspect of the environment.

In luxury retail spaces, the use of PVD stainless steel sheets goes beyond aesthetics. Their combination of durability, consistent finishes, and customizable options ensures that every display, fixture, and surface reflects the brand’s premium identity. By integrating these sheets, retailers create spaces that not only look luxurious but also maintain that appearance over time, providing both functional performance and a memorable customer experience.