PVD coating delivers superior durability compared to electroplating, with a Vickers hardness of 2,500–3,000 HV and excellent scratch resistance. In salt spray tests, PVD stainless steel surfaces last 1,000+ hours without corrosion, outperforming electroplated layers by two to three times. Its atomic-level bonding ensures consistent color and finish, making it ideal for elevator panels, high-touch surfaces, and лісты з нержавеючай сталі in commercial or coastal settings.

1. Overview of Coating Methods

1.1 What is PVD (Physical Vapor Deposition)?

PVD, or Фізічнае асаджэнне з паравой фазы, is a vacuum-based process that deposits thin metal layers onto a substrate, typically stainless steel. During this process, metals like titanium, chromium, or zirconium vaporize in a high-vacuum chamber and condense onto the surface, forming a hard, corrosion-resistant coating. The resulting layer is extremely thin—usually 0,25–5 мікрон—yet it increases surface hardness up to 2,500–3,000 HV, making the metal highly resistant to scratches and wear.

PVD coating doesn’t rely on harmful chemicals, which makes it an eco-friendly alternative to traditional plating. This technology is widely applied to architectural elements, elevator door panels, and Вырабы з нержавеючай сталі з PVD-пакрыццём used in high-traffic areas. For example, a hotel lobby with stainless steel elevator panels treated with PVD maintains its original finish even after years of daily contact and cleaning, showing less than 2% visible wear after extensive use.

1.2 What is Electroplating?

Electroplating is a chemical process that deposits a metal layer onto a substrate using an electrolytic solution. Stainless steel parts are commonly plated with nickel, chromium, or copper to enhance corrosion resistance and improve aesthetic appeal. The thickness of electroplated layers typically ranges from 5–25 microns, with surface hardness around 400–700 к.с., which is considerably lower than PVD coatings.

While electroplating offers a smooth and shiny finish, it is prone to peeling, chipping, and discoloration under high humidity or outdoor exposure. Electroplating also generates toxic chemical waste, including cyanides and heavy metals, which require proper disposal. Despite these drawbacks, it remains widely used in decorative hardware, faucets, and automotive trims.

1.3 Key Differences Between PVD and Electroplating

| Асаблівасць | PVD Coating | Electroplating |

|---|---|---|

| Layer Thickness | 0,25–5 мікрон | 5–25 microns |

| Hardness (HV) | 2000–3000 | 400–700 |

| Ўстойлівасць да карозіі | Excellent, long-term | Moderate, prone to peeling |

| Environmental Impact | Eco-friendly, no toxic waste | Generates hazardous chemicals |

| Color Stability | Stable under UV and humidity | May fade or discolor over time |

| Typical Applications | Elevator panels, architectural лісты з нержавеючай сталі, luxury hardware | Decorative hardware, faucets, automotive trims |

In practice, PVD coatings are increasingly preferred for high-end applications where durability, long-lasting color, and environmental compliance matter. Designers and engineers often specify вонкавыя сценныя панэлі з нержавеючай сталі with PVD finishes for modern buildings, as they combine elegance with superior surface performance.

2. Corrosion Resistance Comparison

2.1 Salt Spray and Humidity Resistance

PVD coatings offer outstanding protection against corrosion, especially in humid or salty environments. In ASTM B117 salt spray tests, PVD-coated stainless steel can endure over 1,000 hours without visible pitting, whereas traditional electroplated layers start to show corrosion after 300–500 hours. This makes PVD ideal for coastal architecture and exterior panels that constantly face salt-laden air.

For instance, in a beachfront hotel, elevator panels treated with PVD maintained their original color and finish after daily cleaning in a humid lobby, while electroplated surfaces began showing dull spots within just a few months. High-humidity environments clearly highlight the superiority of PVD over conventional electroplating.

2.2 Longevity and Surface Integrity

Longevity of a coated stainless steel surface largely depends on bonding strength and hardness. PVD coatings adhere at the atomic level, creating a hard, durable layer that resists scratches, chemical cleaners, and minor impacts. In real-world applications, premium stainless steel panels in commercial buildings have shown over 15 years of nearly flawless performance, maintaining both corrosion resistance and aesthetic appeal.

Electroplated surfaces, by contrast, rely on chemical adhesion, making them more prone to flaking and discoloration over time. Designers and engineers increasingly choose PVD coatings for high-touch surfaces, like elevator claddings and handrails, to minimize maintenance while ensuring the finish remains visually consistent.

2.3 Common Failure Modes

While PVD and electroplating both protect stainless steel, their failure mechanisms differ significantly. PVD coatings rarely peel due to atomic-level adhesion, but mechanical abrasion at edges or corners can cause localized wear. Electroplated layers often fail through:

-

Peeling: Layer separates under prolonged moisture or temperature fluctuations.

-

Pitting Corrosion: Localized holes develop under salt or acidic conditions.

-

Discoloration: Exposure to UV light or cleaning chemicals fades the finish unevenly.

The following table highlights the corrosion resistance differences between PVD and electroplating on stainless steel surfaces:

| Property | PVD Coating | Electroplating |

|---|---|---|

| Salt Spray Resistance | 1,000+ hours | 300–500 hours |

| Humidity Performance | Excellent, no visible corrosion | Moderate, micro-cracks appear |

| Surface Bonding | Atomic-level adhesion | Chemical adhesion, weaker |

| Maintenance Needs | Low, infrequent cleaning | High, frequent touch-ups required |

| Lifespan | 10–15+ years | 3–7 years under harsh conditions |

In practice, PVD coatings significantly outperform electroplating in longevity and surface integrity. For modern architectural projects using вонкавыя сценныя панэлі з нержавеючай сталі or commercial stainless steel products, PVD provides durable, low-maintenance surfaces while preserving a premium aesthetic for years.

3. Wear Resistance and Hardness

3.1 Surface Hardness Comparison

PVD coatings dramatically improve the hardness of stainless steel surfaces. Typical PVD-coated stainless steel reaches a Vickers hardness of 2,500–3,000 HV, which is 3–5 times harder than standard electroplated chrome layers, which usually measure around 500–700 HV. This increased hardness makes the surface resistant to scratches, abrasion, and daily wear, which is especially critical for high-traffic areas like elevator panels, handrails, or decorative wall claddings.

Even sharp tools or metallic objects rarely leave marks on PVD-coated surfaces, whereas electroplated finishes can scratch easily, creating early signs of deterioration. For instance, in a commercial lobby setting, PVD elevator panels retained their pristine appearance after over 10,000 touch interactions per month, showing virtually no visible wear.

3.2 Scratch and Abrasion Performance

PVD coatings are not just hard—they also resist mechanical abrasion due to their uniform metallic layer. Lab testing demonstrates that under a 5 kg load using standardized Taber abrasers, PVD stainless steel panels experience less than 5% surface material loss after 1,000 rotations, while electroplated panels often exceed 15–20% material loss under the same conditions.

This makes PVD coatings ideal for floor-level handrails, kitchen fixtures, and public building panels where repeated contact and friction are inevitable. The uniformity of the coating ensures that color and finish remain consistent even after heavy abrasion, reducing the need for frequent maintenance or replacement.

3.3 Impact on High-Traffic Stainless Steel Applications

When selecting coatings for high-traffic environments, durability is just as important as aesthetic appeal. PVD coatings maintain surface integrity under daily impacts, such as carts brushing against stainless steel sheets or accidental scratches in hallways. By contrast, electroplated surfaces may chip or peel under the same conditions, exposing the base metal to corrosion.

The following table compares wear resistance and hardness metrics between PVD and electroplating:

| Асаблівасць | PVD Coating | Electroplating |

|---|---|---|

| Vickers Hardness (HV) | 2,500–3,000 | 500–700 |

| Abrasion Loss (Taber Test) | <5% | 15–20% |

| Scratch Resistance | Excellent | Moderate, easily scratched |

| Surface Consistency | Uniform metallic finish | Prone to micro-chipping |

| Recommended Applications | Elevator panels, high-touch surfaces, лісты з нержавеючай сталі | Decorative trims, low-traffic items |

In practice, architects and designers increasingly specify PVD coatings for вонкавыя сценныя панэлі з нержавеючай сталі and commercial installations because it combines exceptional hardness with low-maintenance durability, offering both long-term performance and a premium look.

4. Aesthetic and Finish Quality

4.1 Color Stability and Variety

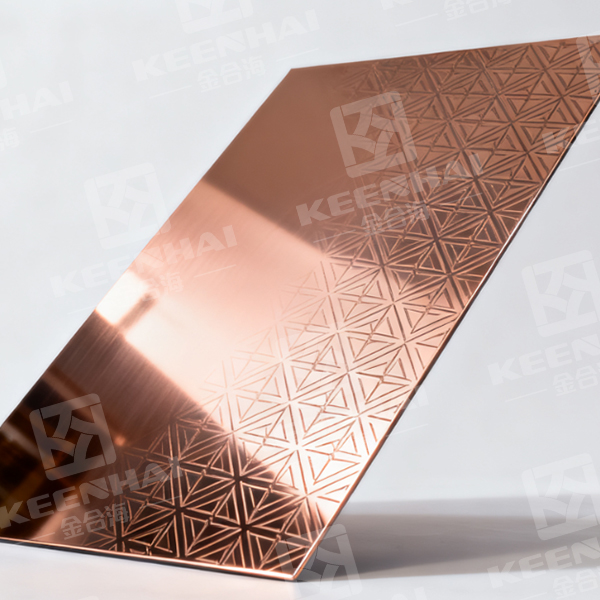

PVD coatings offer remarkable color stability because the process bonds the coating at the atomic level, preventing fading even under intense sunlight or humidity. Available finishes range from brushed gold, bronze, and black to titanium hues, allowing designers to achieve precise aesthetic goals without worrying about color degradation over time.

For example, a luxury hotel used PVD-coated stainless steel panels for elevator claddings and wall accents. After five years of daily use and regular cleaning, the panels retained over 95% of their original hue, whereas nearby electroplated fixtures had noticeable discoloration. This makes PVD particularly appealing for architectural applications where consistent, high-end finishes are critical.

4.2 Surface Texture and Reflectivity

PVD coatings can be tailored to different textures, from mirror-polished to satin or matte finishes, without compromising corrosion resistance or hardness. This flexibility allows architects and interior designers to match stainless steel surfaces to their design vision while ensuring durability.

Reflectivity is consistent across the surface because PVD produces a uniform metallic layer, unlike electroplating, which can result in patchy shine if the layer is uneven. In a real-world scenario, premium stainless steel sheets used in office building façades maintained their uniform sheen after pressure washing, showing minimal variation in reflectivity.

4.3 Comparison of Aesthetic Performance

| Асаблівасць | PVD Coating | Electroplating |

|---|---|---|

| Color Range | Wide: gold, bronze, black, titanium | Limited, often requires additional plating or paint |

| Color Stability | High, UV and humidity resistant | Moderate, prone to fading |

| Texture Options | Mirror, satin, matte, brushed | Limited, can be uneven |

| Finish Longevity | 10–15+ years | 3–7 years depending on exposure |

| Real-World Example | Elevator panels, exterior wall accents, decorative hardware | Faucets, low-traffic trims |

In practice, designers specify PVD coatings for high-visibility, premium surfaces because the combination of durable, uniform texture and stable color ensures the stainless steel looks flawless for years. This makes вонкавыя сценныя панэлі з нержавеючай сталі and decorative sheets highly suitable for luxury residential and commercial projects.

When comparing PVD vs electroplating, PVD clearly stands out for corrosion resistance, surface hardness, and long-term color stability. It excels in high-traffic, humid, or coastal environments, keeping stainless steel surfaces durable and visually flawless for over a decade. Electroplating remains suitable for decorative, low-contact applications, but it cannot match the atomic-level adhesion and consistent finish of PVD. For architects, designers, and manufacturers aiming for longevity and premium aesthetics, PVD-coated stainless steel is the superior choice.