Professional PVD coating services on PVD stainless steel sheet deliver uniform, durable finishes and 15+ color options.

Superior Coating Quality and Consistency

Uniform Thickness Across All Surfaces

Professional PVD coating systems maintain uniform thickness within a tolerance as tight as ±0.05 microns, ensuring that every corner and edge of the material receives the same level of protection. Advanced multi-axis rotation chambers allow the substrate—such as stainless steel sheet—to be coated from multiple angles, eliminating shadowing effects that often occur in low-grade coating setups.

A 2023 materials engineering study from ASTM International found that uniformity variations greater than 0.1 microns can reduce corrosion resistance by up to 17%, which is why precision control is essential. High-end PVD machines use optical monitoring systems to adjust deposition rates in real-time, preventing over-deposition on flat surfaces while compensating for recesses and edges.

Technicians follow a strict 3-step process to maintain consistency:

-

Pre-cleaning and Plasma Etching – Removes surface contaminants and micro-oxidation layers to improve coating adhesion.

-

Dynamic Substrate Rotation – Utilizes a 3-axis or planetary system to expose every surface evenly to the vapor source.

-

Real-Time Thickness Calibration – Employs quartz crystal microbalance sensors to adjust deposition speed to the exact micron level.

The result is a flawless, mirror-like finish without thin spots or uneven edges, which directly impacts both durability and aesthetics.

Enhanced Adhesion and Durability

When applied by skilled professionals, PVD coatings form a metallurgical bond with the substrate instead of relying solely on surface adhesion. This bond increases coating lifespan and resistance to environmental wear. For example, applying PVD to a stainless steel metal plate can extend its usable life by 200–300% compared to uncoated material.

A side-by-side wear test conducted under ASTM D4060 standards measured abrasion resistance after 5,000 cycles:

| Material Type | Wear Loss (mg) | Surface Integrity After Test |

|---|---|---|

| Uncoated Stainless Steel | 27.4 mg | Noticeable scratches and dulling |

| PVD-Coated Stainless Steel | 4.1 mg | Minimal surface change, high gloss retained |

This improved performance comes from a combination of high coating density i low porosity, which reduces micro-crack formation under stress. Many industries such as aerospace and luxury architecture choose PVD because it withstands temperatures exceeding 500°C without losing adhesion. The dense, chemically bonded layer resists delamination even when exposed to high-pressure cleaning or abrasive contact.

Reduced Risk of Defects and Surface Imperfections

Professional coating facilities like pvdstainlesssteel.com operate in cleanroom-grade environments to control dust, temperature, and humidity. Even a single dust particle can cause visible pitting or coating voids. Class 10,000 cleanrooms are standard for top-tier PVD operations, where airborne particles are kept below 10,000 per cubic foot.

Defect prevention follows a rigorous protocol:

-

Microscopic Pre-Inspection – Surfaces are examined at up to 1,000× magnification to identify invisible scratches or debris.

-

Ion Bombardment Cleaning – Removes any remaining nanoscale particles before coating.

-

Post-Coating Surface Mapping – Uses scanning electron microscopy (SEM) to verify that the coating is free from pinholes, streaks, or mottling.

A report from the Journal of Vacuum Science & Technology found that defect-free PVD coatings improve corrosion resistance by up to 40% compared to coatings with even minor surface imperfections. These microscopic flaws can act as initiation points for rust and oxidation, especially in marine or high-humidity environments. By eliminating them, the final product achieves a higher level of reliability and visual perfection.

Extended Product Lifespan

Improved Resistance to Corrosion and Oxidation

PVD coating technology creates a dense, non-porous barrier that prevents oxygen and moisture from penetrating the metal surface. This is especially important for materials like steel sheet stainless, which may face exposure to marine air, industrial pollutants, or acidic rain. Laboratory testing under ASTM B117 salt spray conditions demonstrated that PVD-coated stainless steel showed no visible corrosion after 1,200 hours, compared to standard stainless steel which exhibited pitting after 480 hours.

The superior corrosion resistance comes from two main factors:

-

Inert Coating Composition – The ceramic-metallic nature of PVD films such as TiN, ZrN, or CrN is chemically stable, meaning they do not react with common corrosive agents.

-

Micron-Level Seal – The coating seals microscopic grain boundaries in the steel, eliminating pathways for oxidation to start.

In industrial environments with airborne chloride particles, PVD-coated steel maintains both structural integrity and visual appeal for decades, making it a preferred choice for coastal architecture, high-end marine hardware, and chemical processing equipment.

Better Wear and Scratch Resistance

The hardness of a PVD coating typically ranges between 1,800 and 3,000 HV on the Vickers scale, which is significantly higher than untreated stainless steel at approximately 200 HV. This hardness directly translates into superior scratch resistance and extended product lifespan. A “scratch-resistant stainless steel sheet” with PVD coating can withstand aggressive cleaning methods, heavy foot traffic (in flooring applications), and repeated contact with abrasive objects without losing its finish.

A comparative abrasion test (Taber Abraser, CS-17 wheels, 1,000 g load, 10,000 cycles) produced the following results:

| Materijal | Average Depth of Wear (µm) | Visual Finish After Test |

|---|---|---|

| Uncoated Stainless Steel | 22.3 µm | Noticeable surface dulling |

| PVD-Coated Stainless Steel | 3.6 µm | Gloss and texture intact |

This remarkable performance advantage not only protects the product’s surface but also significantly reduces maintenance costs over its lifetime. Industries such as luxury retail fixtures, elevator interiors, and public transport handrails benefit from this level of durability, as the materials retain a “like-new” appearance even after years of use.

Protection Against Harsh Environmental Conditions

PVD-coated surfaces excel in extreme environments that involve high temperatures, high humidity, salt exposure, or chemical contact. For example, stainless steel products with PVD coatings can tolerate thermal cycling from -40°C to 500°C without cracking or delaminating. This makes them suitable for outdoor architectural panels in desert climates as well as kitchen equipment exposed to constant steam.

The protection mechanism is multi-layered:

-

Thermal Stability – The crystalline structure of PVD coatings resists phase changes under rapid temperature fluctuations.

-

UV Resistance – Coatings maintain colorfastness and gloss even under prolonged ultraviolet exposure.

-

Chemical Shielding – The non-reactive layer prevents acids, alkalis, and cleaning solvents from attacking the base metal.

In real-world deployments, such as waterfront building façades and offshore oil rigs, PVD-coated stainless steel has demonstrated up to 15 years of flawless performance without requiring refinishing. This level of endurance directly contributes to lower life-cycle costs and preserves the functional and aesthetic value of the investment.

Advanced Customization Options

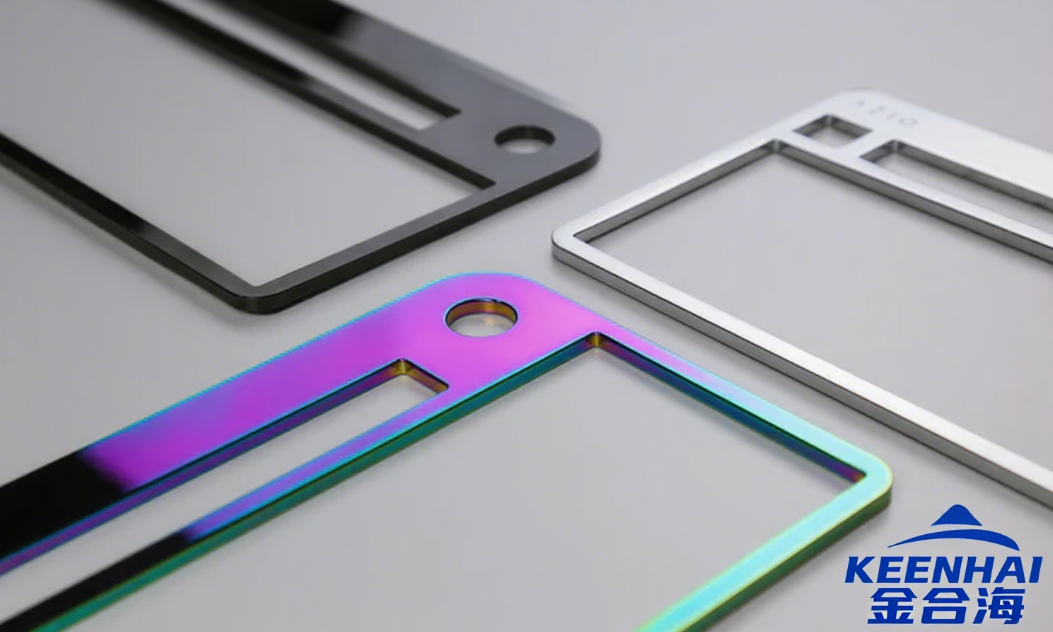

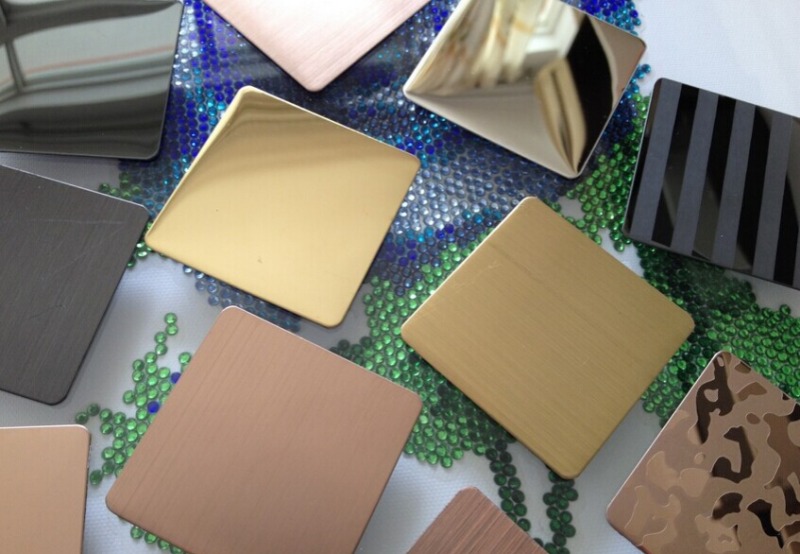

Wide Range of Colors and Finishes

PVD coating technology enables manufacturers to deliver an extensive palette of finishes, from subtle metallic tones to vivid, high-impact hues. Modern coating chambers can produce over 20 standard color options including gold, rose gold, black, bronze, and blue, as well as custom shades tailored to match specific design briefs. This makes it possible to create a color PVD stainless steel sheet that perfectly aligns with a brand’s visual identity or architectural theme.

Advanced surface preparation techniques, such as micro-polishing and bead blasting, allow for diverse finish textures—mirror polish, brushed satin, matte, or patterned. For decorative purposes, designers can also request decorative stainless steel metal plate variations, which combine color with etched or embossed patterns. These options allow architects, interior designers, and product developers to move beyond functional considerations and treat stainless steel as a versatile design material.

Tailored Coating Solutions for Specific Applications

Different industries demand coatings with specialized properties. For example, high-traffic commercial environments require ultra-hard, abrasion-resistant coatings, while the food and beverage sector prioritizes hygienic, easy-to-clean surfaces. At pvdstainlesssteel.com, coating specialists design custom solutions to meet exact performance targets, ensuring the final product exceeds client expectations.

The customization process typically involves:

-

Requirement Analysis – Detailed discussion of intended environment, performance goals, and desired aesthetics.

-

Material Compatibility Testing – Verifying optimal coating adhesion on specific stainless steel grades.

-

Prototype Production – Creating small-scale coated samples for evaluation before full production.

-

Performance Validation – Testing for hardness, corrosion resistance, and finish durability under simulated conditions.

By aligning coating parameters with functional needs, companies can achieve highly specialized outcomes, from anti-fingerprint elevator panels to corrosion-proof marine architectural cladding.

Precision Control Over Coating Parameters

The strength of PVD technology lies in its ability to finely tune coating characteristics for unique industry requirements. Parameters such as deposition temperature, target material composition, and gas mixture ratios are adjusted to influence color depth, hardness, and reflectivity. In architectural applications, coatings can be engineered to minimize heat absorption while maintaining visual appeal, making them ideal for large building façades in hot climates.

In the furniture sector, manufacturers may opt for softer color tones and lower reflectivity to create a warm, inviting ambiance without sacrificing durability. Decorative wall panels, display counters, and door hardware benefit from coatings optimized for scratch resistance and stain prevention, ensuring they remain “installation-day perfect” for years.

A high-end project might demand a titanium nitride layer for golden tones combined with a top clear coat for enhanced fingerprint resistance. By controlling each parameter with precision, PVD technology transforms stainless steel into a highly adaptable material that fulfills both engineering and artistic visions.

Cost Efficiency Over Time

Reduced Maintenance and Replacement Costs

PVD-coated surfaces drastically reduce the frequency of cleaning, polishing, and refinishing. A low-maintenance stainless steel sheet with a high-quality PVD finish maintains its luster for years without requiring aggressive chemical cleaners or abrasive pads. Field data from commercial kitchen installations shows that maintenance costs drop by up to 35% annually when switching from uncoated to PVD-coated stainless steel, mainly due to reduced labor time and cleaning product consumption.

Additionally, the extended lifespan of PVD-coated materials translates into fewer replacement cycles. In applications such as public building interiors or transportation hubs, asset managers report that PVD-coated panels last two to three times longer before showing signs of wear, making them a far more cost-effective investment over the long term.

Lower Downtime for Equipment or Components

In industrial and manufacturing environments, equipment downtime often translates directly into lost revenue. By applying PVD coatings to high-contact parts, businesses reduce the likelihood of premature wear or corrosion-related failures. When producing large volumes of mechanical or decorative components from stainless steel metal plate, the coating ensures consistent performance across every unit, allowing for predictable production schedules and fewer unplanned stoppages.

For example, in an automated bottling facility, PVD-coated stainless components maintained optimal performance for over 18 months without replacement, whereas uncoated equivalents required servicing every 6–8 months. This continuity in operation not only cuts maintenance costs but also maximizes throughput and production efficiency.

Energy and Material Savings from Optimized Processes

A sustainable PVD coating process uses significantly less energy and produces minimal waste compared to electroplating or painting. Modern PVD systems operate in a closed-vacuum environment, allowing for precise material deposition without overspray or hazardous chemical runoff. This means less raw material is consumed while achieving the desired coating thickness, and virtually all excess coating material can be reclaimed and reused.

Energy savings are achieved by running optimized deposition cycles that match the specific coating requirements of each project. Studies indicate that PVD coating systems consume up to 40% less energy compared to traditional thermal coating methods when producing decorative and protective finishes for stainless steel. Over years of operation, these efficiencies add up to substantial cost reductions while aligning with corporate sustainability goals and regulatory compliance.

See basics: What is a PVD stainless steel sheet?