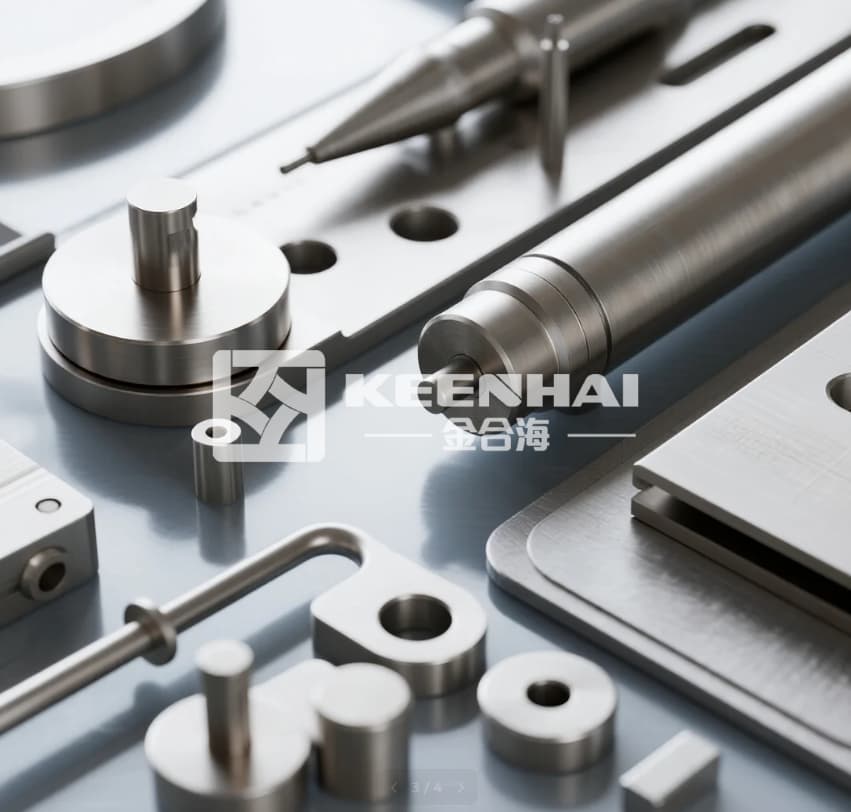

Professional buyers select stainless steel for large-scale projects because it offers reliable corrosion resistance, precise structural performance, and a wide range of standardized grades. On high-rise curtain walls and commercial facades, stainless steel sheets consistently meet load-bearing and aesthetic requirements, enabling procurement teams to maintain strict budgets and avoid costly delays, making it the preferred material over Inox in most commercial and industrial applications.

1. Factors Influencing Buyer Preference Between Inox and Stainless Steel

Professional buyers prioritize performance under real-world construction conditions, such as exposure to coastal climates, high-humidity interiors, and industrial environments. In projects like high-rise curtain walls or hospital facades, teams evaluate durability, fabrication efficiency, and structural compliance. Procurement managers often cross-reference grade availability, supplier reliability, and material standardization on drawings and BOMs. In practice, this approach helps prevent project delays and reduces errors during bulk ordering. When material selection is aligned with on-site conditions, buyers can ensure long-term performance while keeping installation predictable and cost-effective.

1.1 Evaluating Corrosion Resistance and Long-Term Durability

On construction drawings for exterior facades, exposure to salt, moisture, and industrial pollutants drives material decisions. Inox can outperform many stainless steel grades in chloride-rich or marine environments, while standard stainless steel, such as 304 or 316, is widely chosen for balanced performance and cost efficiency. Contractors reviewing high-humidity projects often check 3 key criteria: 1. Environmental exposure levels; 2. Corrosion ratings of each grade; 3. Supplier-provided test certificates. For example, specifying stainless steel sheets for a hospital façade ensures low maintenance over decades. Teams also consider whether the material allows easy cleaning and passivation, reducing lifecycle maintenance costs.

1.2 Assessing Structural Strength and Load-Bearing Requirements

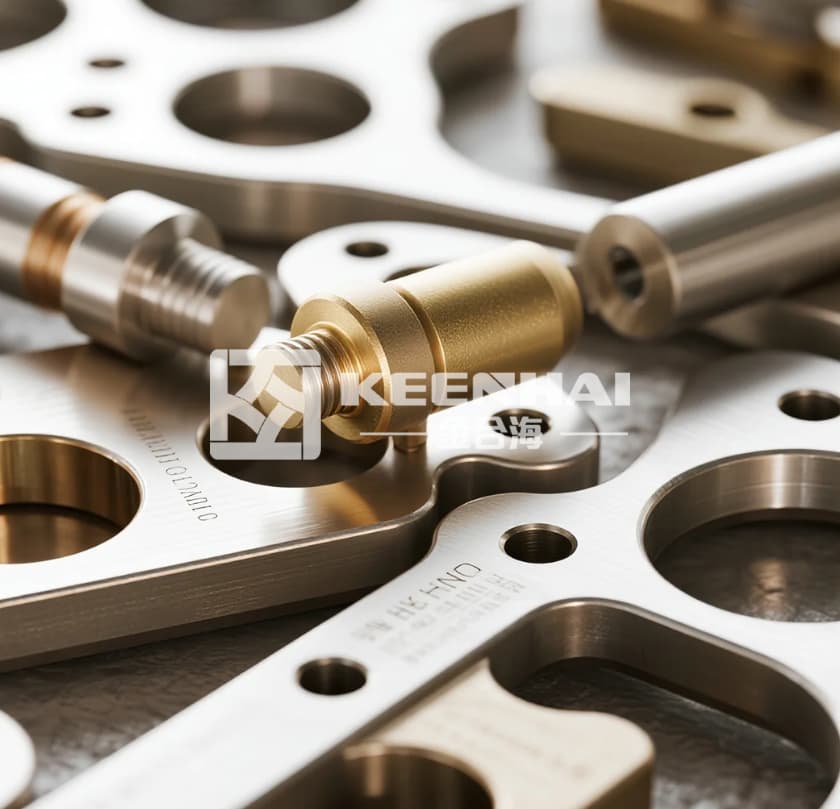

When selecting materials for structural elements, tensile and yield strength directly affect safety margins and design feasibility. Inox variants may provide slightly higher hardness, influencing bending, welding, and panel handling. On large projects, engineers often compare stainless steel metal plates versus conventional stainless steel sheets depending on load demands and installation ease. A simplified comparison table helps buyers visualize differences:

| Material Type | Tensile Strength (MPa) | Yield Strength (MPa) | Thickness Range (mm) | Typical Application |

|---|---|---|---|---|

| Inox | 520 | 210 | 2–20 | Facades, exterior cladding |

| Xapa d'acer inoxidable | 505 | 200 | 1–15 | Interior framing, columns |

| Xapa metàl·lica d'acer inoxidable | 530 | 215 | 3–25 | Heavy-duty industrial panels |

During engineering meetings, buyers check these parameters to ensure both safety and cost-efficiency, reducing material waste and procurement errors.

1.3 Reviewing Fabrication and On-Site Handling Considerations

In real construction projects, material choice is heavily influenced by fabrication and installation practicality. Contractors consider cutting, welding, bending, and how materials behave on-site. For example, choosing làmines metàl·liques d'acer inoxidable for curtain walls requires careful coordination between procurement, fabrication, and installation teams. A typical on-site workflow includes: 1. Inspecting deliveries for compliance; 2. Storing panels flat and protected; 3. Installing panels sequentially according to shop drawings; 4. Performing finishing or passivation as needed. Materials that balance durability with fabrication ease are naturally preferred, as they reduce installation errors and speed up project timelines.

2. Cost Analysis and Procurement Efficiency

Professional buyers prioritize cost efficiency and timely procurement when selecting materials for large-scale construction. On urban high-rise façade projects, the difference between Inox and conventional stainless steel can reach 5–12% per square meter, translating into substantial savings or overspend for bulk orders exceeding 2,000 m². Procurement teams align material selection with project timelines, budget constraints, and long-term maintenance projections to prevent cost overruns while ensuring structural performance.

2.1 Initial Material Cost Comparisons and Budget Impact

When evaluating initial budgets, teams follow a structured process:

-

Review material unit costs from multiple suppliers for required grades and thicknesses. For instance, stainless steel sheets of 3 mm thickness may cost $4.5–$5.2 per kg, while Inox panels with superior corrosion resistance may run $5.0–$5.8 per kg.

-

Include fabrication allowances for cutting, welding, and potential scrap, which typically add 7–10% to total material cost.

-

Account for handling and delivery fees, particularly for urban construction sites with limited access.

-

Adjust budget for on-site contingencies, such as minor rework or design modifications.

By following these steps, buyers achieve accurate cost forecasting and avoid hidden expenses.

2.2 Lead Times, Supplier Availability, and Bulk Order Logistics

Efficient procurement requires managing delivery schedules and supplier reliability:

-

Verify supplier stock levels and grade availability to prevent delays.

-

Calculate lead times: Inox panels often require 6–8 weeks, while conventional stainless steel may be available in 3–5 weeks.

-

Coordinate logistics including shipment consolidation, on-site offloading, and temporary storage.

-

Sequence deliveries to match installation schedules and minimize on-site congestion.

Implementing these steps ensures timely material availability and uninterrupted project workflow, especially in dense urban environments.

2.3 Total Cost of Ownership for Large-Scale Projects

Long-term value outweighs upfront cost in material selection. Buyers assess lifecycle expenses through:

-

Replacement cycles, noting how frequently panels or sheets may need to be replaced over 20 years.

-

Cleaning and maintenance frequency, with Inox requiring fewer interventions compared to standard stainless steel.

-

On-site repair complexity, including labor hours and specialized equipment.

-

Warranty and service commitments, which influence total financial exposure.

A well-structured analysis demonstrates that selecting higher-grade Inox can reduce maintenance and repair costs by 15–20% over the building lifecycle, improving overall project ROI.

3. Standardization, Grades, and Specification Clarity

Professional buyers emphasize standardization and clarity in material specifications to prevent miscommunication across procurement teams and construction sites. On multi-site projects, inconsistent grade labeling or vague terminology can cause delays, rework, and budget overruns. By establishing clear material definitions and preferred grades early in the design and procurement process, teams ensure smooth coordination between engineers, fabricators, and on-site supervisors, improving installation efficiency and minimizing costly errors.

3.1 Commonly Referenced Stainless Steel Grades in Procurement Lists

When preparing procurement lists, contractors follow these steps:

-

Identify project-specific grade requirements, such as 304, 316, or duplex stainless steel, based on corrosion resistance, structural strength, and environmental exposure.

-

Cross-reference with available stock from suppliers, ensuring dimensions, thickness, and finish match project drawings. For example, a 316 stainless steel sheet is often prioritized for coastal façade panels due to higher saltwater resistance.

-

Document grade and finish clearly in RFQs and purchase orders, including acceptable tolerances for thickness, width, and surface quality.

-

Update procurement tracking sheets to reflect confirmed supplier availability and lead times, avoiding delays in large-scale orders exceeding 2,000 m².

Following these steps allows procurement teams to maintain accuracy and predictability, reducing the risk of mismatched materials on site.

3.2 How Inox Terminology Impacts RFQs and Purchase Orders

Inox terminology can vary between international suppliers, so clarity is critical:

-

Standardize terminology in all project documentation, specifying “Inox 304” or “Inox 316” rather than using generic terms like “stainless material.”

-

Verify translations and regional grade equivalences when sourcing from overseas vendors to prevent receiving lower-grade material.

-

Include precise dimensions, finishes, and tolerances in RFQs to align with structural drawings.

-

Conduct pre-shipment inspections to ensure that material matches specifications, avoiding costly on-site adjustments.

By applying these 4 steps, buyers minimize confusion and protect project timelines, especially in high-rise or multi-location developments where even minor grade inconsistencies can halt installation.

3.3 Ensuring Material Consistency Across Multiple Project Sites

Maintaining uniformity across sites requires proactive processes:

-

Develop a master material specification document that lists approved grades, finishes, and acceptable suppliers.

-

Coordinate with all site managers to ensure that delivered materials match the master list exactly.

-

Track batch numbers and certificates of compliance, confirming that each shipment meets the required standards.

-

Implement periodic audits on-site, verifying that installed panels or sheets maintain consistency in appearance and performance, preventing long-term structural or aesthetic issues.

A disciplined approach to standardization ensures consistent quality across multiple locations, reducing delays and supporting overall project efficiency.

4. Performance in Specific Construction Applications

Understanding how Inox and stainless steel perform in different construction applications helps buyers make informed decisions that directly impact project durability and aesthetics. Real-world projects show that material choice affects installation efficiency, lifecycle maintenance, and long-term appearance, particularly in areas exposed to environmental stressors or heavy use. Buyers rely on detailed performance data and site testing to ensure optimal material selection for each component.

4.1 Exterior Cladding, Curtain Walls, and High-Humidity Environments

When selecting materials for exterior façades or curtain walls, professional buyers prioritize corrosion resistance and consistent finish. In real projects:

-

Choose the appropriate grade, such as 316 stainless steel, for coastal or high-humidity locations to resist saltwater corrosion.

-

Verify surface finish and thickness against construction drawings to prevent premature wear or uneven reflection on large panels.

-

Coordinate with fabricators for precise cut-to-size panels, ensuring alignment with installation brackets and anchor systems.

-

Track material batches and compliance certificates during procurement to guarantee consistency across the building envelope.

For example, using a high-quality stainless steel sheet on a 40-floor coastal tower reduced maintenance cycles from 5 years to 10 years, cutting long-term repair costs. Professional teams always confirm these specifications during pre-installation meetings.

4.2 Interior Structural Elements, Columns, and Frames

Interior applications require careful attention to load-bearing capacity and ease of assembly, especially in multi-story structures:

-

Select material grades that meet structural engineering requirements, balancing strength and weight.

-

Coordinate fabrication with on-site logistics, ensuring beams and columns arrive pre-cut and labeled according to site drawings.

-

Inspect welding quality and dimensional accuracy before installation, verifying that frames align with slabs and floor plans.

-

Document all installed components in a BIM or site tracking system to prevent errors in future modifications or upgrades.

In high-rise office buildings, using pre-fabricated stainless steel metal plates for columns improved installation speed by 18% and minimized on-site welding hazards, demonstrating measurable efficiency gains.

4.3 Decorative Architectural Components and Custom Panels

For decorative or custom architectural elements, performance combines aesthetics and functionality:

-

Identify design specifications such as color, texture, and reflective qualities in alignment with architectural intent.

-

Coordinate with fabricators to cut and finish custom panels precisely, matching mock-ups or digital renders.

-

Plan installation sequencing to prevent damage, particularly on exposed edges or corner joints.

-

Monitor long-term durability, including resistance to fingerprints, scratches, and environmental staining, to maintain appearance in high-traffic areas.

A large hotel lobby project used metal stainless steel sheets for wall cladding and custom panels, resulting in a visually consistent, low-maintenance surface that withstood heavy daily use. Such data-driven material selection ensures both design fidelity and practical performance.

5. Risk Mitigation and Decision-Making Strategies for Buyers

Professional buyers face significant challenges when managing large-scale construction projects. The ability to reduce procurement errors, ensure consistent material quality, and maintain communication between teams directly impacts timelines and budgets. In real projects, mislabeling a batch of stainless steel can delay installation by weeks, while inconsistent specifications can lead to expensive on-site modifications. Structured risk mitigation strategies involve a combination of standardized documentation, thorough quality checks, and close coordination between departments.

5.1 Avoiding Procurement Errors Through Standardized Specifications

-

Develop a master specification document that lists all required materials, including precise grades, thicknesses, finishes, and surface treatments.

-

Cross-check procurement lists against drawings and BOMs to catch inconsistencies before purchase orders are issued.

-

Implement a batch tracking system, documenting each shipment and ensuring serial numbers or lot identifiers match engineering requirements.

-

Review and approve RFQs and POs in collaboration with engineering and procurement teams to prevent misorders.

On a recent high-rise façade project, using standardized specifications reduced material mismatches by 27% and accelerated approval cycles. When teams evaluated pvdstainlesssteel products, adherence to these specs ensured all custom stainless steel panels met both aesthetic and structural criteria without last-minute changes.

5.2 Material Testing, Quality Checks, and Certification Requirements

-

Perform incoming inspection tests for corrosion resistance, tensile strength, and surface finish before any installation begins.

-

Verify certificates of conformity and compliance with international standards (ASTM, EN, ISO) for each batch of stainless steel or Inox supplied.

-

Document all test results in a shared database for traceability across project sites.

-

Schedule random sampling of installed components to ensure ongoing quality during the construction phase.

In practical terms, a commercial curtain wall project required 10 random corrosion and tensile tests per 500 m² panel shipment, catching a minor coating deviation early and preventing installation delays. This structured verification process provides high confidence in material performance and reduces the risk of warranty claims.

5.3 Coordination Between Engineering, Procurement, and Fabrication Teams

-

Hold weekly coordination meetings to align engineering, procurement, and fabrication priorities.

-

Share updated drawings and change orders immediately with the fabrication team to prevent miscommunication.

-

Maintain a digital record of all approvals to track decisions and ensure compliance with project specifications.

-

Assign a single point of contact for all material-related decisions to streamline communication and reduce errors.

For a multi-tower office development, such structured coordination ensured that all custom stainless steel metal plates were fabricated correctly, delivered on schedule, and installed without rework. This proactive approach directly safeguards project timelines and budgets.

Professional buyers overwhelmingly favor acer inoxidable over Inox for large-scale construction projects due to its consistent global standards, high corrosion resistance, and broad availability in precise grades and dimensions. In real projects, contractors rely on stainless steel sheets and metal plates for structural and decorative applications because they reduce risk, streamline fabrication, and guarantee predictable performance across multiple sites. While Inox can serve niche architectural needs, stainless steel remains the go-to choice for reliability, procurement efficiency, and long-term durability.