Choosing a dependable manufacturer matters. pvdstainlesssteel provides custom stainless steel elevator doors with flexible design options, robust construction, and professional technical support to ensure safe, smooth operation.

1. Key Criteria for Choosing a Reliable Manufacturer

1.1 Material Quality and Finish Options

Material quality is the foundation of a reliable custom elevator door. Stainless steel remains the most widely used option due to its durability, corrosion resistance, and low maintenance. Type 304 stainless steel works well for most commercial and residential applications, while type 316 is preferred for high-humidity or coastal environments due to its enhanced corrosion resistance. For example, a beachfront luxury hotel in Miami installed stainless steel elevator doors to withstand the salty, humid air while maintaining a polished appearance.

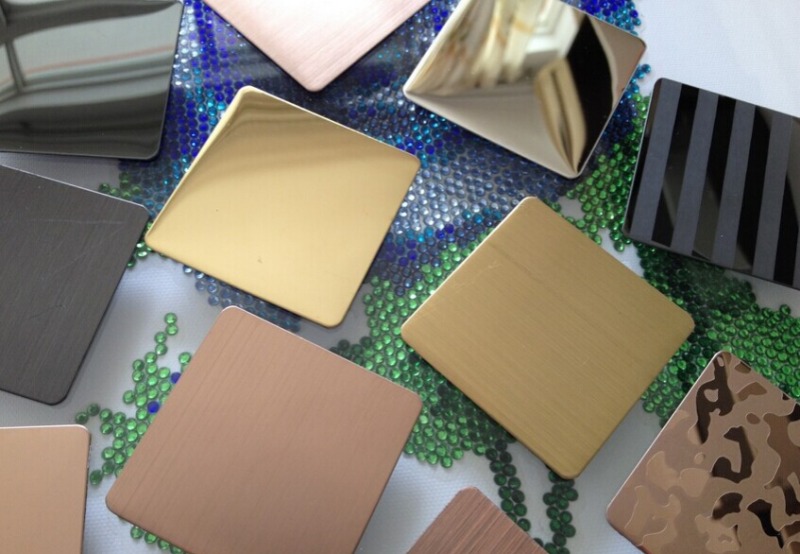

Finish options are equally important for aesthetics and durability. Brushed, mirror, or PVD-coated finishes not only enhance the visual appeal but also help protect surfaces from scratches and fingerprints. In a recent high-rise in Dubai, brushed stainless steel was chosen for service elevators, while lobby doors received a custom PVD gold finish to complement the interior design. Selecting a manufacturer that offers multiple material grades and finishes ensures the doors meet both functional and design expectations.

1.2 Engineering and Customization Capabilities

Customization capabilities are key when evaluating manufacturers. A reliable supplier should accommodate non-standard dimensions, intricate panel designs, and integrated elements like glass inserts or ventilation grilles. Modern manufacturers use CAD modeling and CNC fabrication to deliver precise cuts and consistent quality across all units.

Steps to assess customization capability:

-

Provide detailed architectural drawings and preferred material specifications.

-

Verify if the manufacturer can translate designs into production-ready CAD files.

-

Evaluate their ability to handle multiple custom requests simultaneously without affecting lead times.

-

Check whether the manufacturer offers mock-ups or prototypes for review before mass production.

Residential elevator doors often require specific adjustments for space constraints and quieter operation. Experienced manufacturers can provide residential elevator doors that fit compact shafts while maintaining a polished, durable finish. For instance, a high-end apartment complex in Singapore successfully installed custom stainless steel residential doors with subtle glass panels, ensuring both function and elegance.

1.3 Compliance with Manufacturing Standards

Reliability also depends on adherence to international manufacturing standards. Top manufacturers follow ISO certifications, fire ratings, and mechanical testing protocols to guarantee that doors perform safely and consistently. Compliance includes resistance to impact, wear, and environmental factors like moisture or heat.

Some projects may also require acoustic testing or vibration resistance, particularly in hospitals or high-speed elevator installations. A notable case in London involved installing stainless steel elevator doors that passed strict acoustic tests for a mixed-use tower, ensuring a quieter experience for occupants.

| Compliance Factor | Requirement Level | Practical Impact |

|---|---|---|

| ISO Certification | Mandatory for top suppliers | Ensures quality control and repeatable production |

| Fire Rating | Taas | Protects passengers in emergencies |

| Mechanical & Impact Testing | Taas | Doors withstand thousands of cycles without failure |

| Environmental Resistance | Moderate | Handles humidity, coastal salt air, or temperature swings |

Selecting a manufacturer that prioritizes material quality, customization, and compliance ensures long-lasting, functional, and visually appealing elevator doors. For clients seeking a reliable partner with comprehensive services, pvdstainlesssteel offers a proven track record in delivering custom elevator solutions across commercial and residential projects.

2. Types of Custom Elevator Doors Offered

2.1 Stainless Steel Elevator Doors

Stainless steel elevator doors dominate the commercial market because of their combination of strength, durability, and low maintenance. High-quality 304 stainless steel provides excellent resistance to corrosion and wear, while type 316 is often used in coastal regions or high-humidity environments. Standard commercial doors typically measure 42–48 inches in width and 84–96 inches in height, though custom dimensions are widely available.

Finish options range from brushed and mirror to PVD-coated colors like gold, bronze, or black. The choice affects both aesthetics and surface maintenance. Brushed finishes reduce visible fingerprints, while mirror finishes create a more open and modern look in lobbies. The material thickness usually ranges from 1.2–2.0 mm, balancing durability and weight. Doors with heavier gauge stainless steel tend to have longer lifespans, often exceeding 20 years with proper maintenance.

Power and speed parameters are crucial for high-traffic areas. Commercial stainless steel doors usually operate at 1.0–1.5 meters per second, with motor power between 0.75–1.5 kW depending on size and weight. Maintenance frequency varies by usage; elevators in office towers may require inspection every 6 months, while residential settings can extend to 12 months.

2.2 Residential Elevator Doors

Residential elevator doors focus on space efficiency, noise reduction, and aesthetics. Typical widths range from 28–36 inches, and heights are often 78–84 inches to fit compact home shafts. Materials can include 304 stainless steel, wood accents, or glass panels combined with steel frames. This flexibility allows homeowners to match doors to interior décor while maintaining durability.

Design considerations for residential doors include quieter operation, often achieved with motors under 0.5 kW and reduced door speed of 0.6–0.8 meters per second. Safety sensors prevent accidents, and soft-close mechanisms reduce noise. Lifespan expectations are around 15–20 years for well-maintained stainless steel doors.

Cost factors vary with customization:

-

Standard residential stainless steel doors: $3,500–$5,500 per unit.

-

Doors with decorative finishes, glass inserts, or wood panels: $6,000–$10,000 per unit.

-

Additional motor upgrades or soft-close systems may add $500–$1,200.

Residential elevator doors provide both functionality and design flexibility, making them suitable for high-end homes, boutique hotels, or private office installations.

2.3 Commercial and Industrial Elevator Doors

Commercial and industrial elevator doors prioritize durability, speed, and resistance to heavy usage. They often measure 48–54 inches in width and 84–96 inches in height, with steel thickness of 1.5–2.5 mm for long-term performance. Industrial doors may include reinforced panels, fire-rated materials, or impact-resistant coatings to withstand heavy traffic or equipment movement.

Power ratings typically range from 1.5–3.0 kW, and speed is usually 1.2–1.8 meters per second to handle quick operations in busy buildings. Lifespan for industrial doors can exceed 25 years if maintained properly. Regular inspections and lubrication every 3–6 months ensure smooth operation, especially in factories or transport hubs.

| Feature | Residential Doors | Commercial/Industrial Doors | Notes |

|---|---|---|---|

| Width / Height | 28–36 in / 78–84 in | 48–54 in / 84–96 in | Custom sizes available |

| Material Thickness | 1.0–1.5 mm | 1.5–2.5 mm | Thicker steel increases durability |

| Motor Power | 0.3–0.5 kW | 1.5–3.0 kW | Determines door speed and load handling |

| Speed | 0.6–0.8 m/s | 1.2–1.8 m/s | Faster operation for high-traffic areas |

| Estimated Lifespan | 15–20 years | 20–25+ years | Depends on maintenance |

Some commercial projects integrate glass panels or stainless steel accents for aesthetic purposes, particularly in office lobbies or luxury retail centers. Durable stainless steel elevator doors withstand daily heavy use while maintaining a polished appearance. Industrial facilities often opt for fully reinforced steel doors with minimal decorative features to focus on performance and longevity.

3. Production and Lead Time Considerations

3.1 Standard vs. Custom Production Capacity

Production capacity is a key factor when selecting a reliable elevator door manufacturer. Standard doors, such as basic stainless steel panels, can usually be produced in batches of 50–100 units per week, depending on the factory size. Custom designs—like etched patterns, mixed materials, or non-standard dimensions—require more detailed planning and often reduce throughput to 10–20 units per week.

Manufacturers with automated production lines can maintain high efficiency even with complex orders. Steps to evaluate production capacity include:

-

Assess the number of doors the factory can produce per week for both standard and custom designs.

-

Verify if the manufacturer uses CAD/CAM systems to minimize human error during fabrication.

-

Check whether they maintain inventory for commonly used materials to avoid delays.

-

Determine if multiple production lines operate simultaneously for large-scale projects.

For example, a 40-floor residential tower in Singapore required 60 custom residential elevator doors with glass panels and brushed stainless steel finishes. Only a manufacturer with both CNC fabrication and assembly automation could deliver all units within eight weeks without compromising quality.

3.2 Order Lead Time and Delivery Reliability

Lead time is critical for project scheduling. Standard elevator doors typically have a production lead time of 2–4 weeks, while fully custom doors can take 6–12 weeks. Factors that influence lead time include material availability, design complexity, and order volume.

Delivery reliability also matters. Reliable manufacturers track orders and provide clients with estimated shipping dates, often including buffer time for inspection and adjustments. Some suppliers even offer express production options for urgent projects, usually at an additional 15–25% cost.

A practical comparison of lead times:

| Door Type | Average Lead Time | Notes |

|---|---|---|

| Standard Stainless Steel | 2–4 weeks | Minimal customization, often stocked materials |

| Custom Residential Doors | 6–8 weeks | Includes glass inserts, decorative finishes |

| Custom Commercial/Industrial | 8–12 weeks | Reinforced panels, non-standard dimensions, PVD finishes |

Manufacturers with integrated logistics can coordinate shipment and installation more effectively, reducing downtime for building projects. For instance, a Dubai mall project required 80 doors delivered in staggered shipments to align with elevator installation schedules, and only suppliers with precise lead time tracking met the deadline.

3.3 Factory Equipment and Automation

Advanced equipment and automation significantly affect both quality and speed. Reliable manufacturers employ CNC laser cutting, robotic welding, automated polishing, and robotic assembly lines. These systems ensure consistent panel dimensions, precise finishes, and reduced error rates compared to fully manual production.

Key factors to consider when evaluating factory automation:

-

Laser cutting precision (typically ±0.1 mm) for tight-fitting elevator doors.

-

Robotic welding consistency to prevent warping or misalignment.

-

Automated surface finishing for uniform brushed or PVD coatings.

-

Integrated inspection stations for measuring thickness, alignment, and finish quality.

Automated factories can produce more units with less labor, lowering production cost per unit while maintaining high quality. For example, a high-traffic office complex in London installed stainless steel elevator doors fabricated using robotic welding and automated polishing. Each door maintained uniform thickness of 1.5 mm and precise dimensions, ensuring smooth installation and long-term durability.

For clients, understanding production and lead time considerations allows better project planning, accurate budgeting, and reduces the risk of delays. Manufacturers with modern equipment, sufficient production capacity, and reliable lead times help avoid expensive last-minute adjustments or rushed installations, directly addressing one of the most common pain points in construction projects.

4. Installation and Technical Support

4.1 On-Site Installation Services

On-site installation is the most critical step to ensure elevator doors operate smoothly and safely. Reliable manufacturers provide trained technicians who follow a step-by-step workflow:

-

Pre-Installation Inspection: Check the elevator shaft dimensions, wall alignment, and floor levels. Verify that electrical and mechanical systems are ready for door installation.

-

Unpacking and Material Check: Confirm all panels, frames, and hardware are included and undamaged. For stainless steel doors, check for scratches or dents before mounting.

-

Frame Alignment: Install the door frame using leveling tools and anchors. Precision is essential—misalignment by even 2 mm can affect door operation.

-

Door Panel Mounting: Attach the panels to the frame, ensuring smooth sliding or folding. For heavy stainless steel panels (typically 1.5–2.0 mm thick), mechanical assistance or lifting equipment is recommended.

-

Motor and Control Setup: Connect the door motor, sensors, and control panel. Test opening/closing speed (commonly 0.6–1.5 meters per second depending on type) and adjust force to meet building regulations.

-

Safety Verification: Check sensors, emergency stop functions, and soft-close mechanisms. Confirm smooth operation under load conditions.

-

Final Finish Check: Inspect surface finish, alignment, and aesthetic details. Ensure the polished or PVD coating is uniform without marks.

Manufacturers often include a checklist for installation teams to ensure nothing is overlooked, reducing callbacks and warranty claims. High-end projects, like a luxury residential tower in Singapore, required precise alignment of glass-inset stainless steel elevator doors, which technicians accomplished using laser-guided measuring tools.

4.2 Post-Installation Maintenance

Proper maintenance extends the lifespan of elevator doors and prevents operational issues. A typical maintenance schedule includes:

-

Monthly Visual Inspection: Look for scratches, misalignment, and wear on rollers or hinges.

-

Quarterly Lubrication: Apply appropriate lubricant to moving parts such as tracks, rollers, and motor components. Stainless steel parts resist corrosion, but lubrication ensures quieter operation.

-

Biannual Functional Test: Check sensor responsiveness, motor performance, and door speed. Adjust settings if the door opens or closes too fast or slow.

-

Annual Professional Inspection: Have certified technicians inspect electrical connections, check torque on screws/anchors, and test emergency features.

Cost-effective maintenance plans may include replacement of high-wear components like rollers or motor brushes. For residential doors, soft-close and noise reduction systems often need calibration every 12–18 months.

4.3 Troubleshooting and Spare Parts Availability

Rapid troubleshooting prevents downtime and ensures safety. Common elevator door issues include misalignment, sensor malfunction, motor noise, or panel scratches. Steps for troubleshooting:

-

Identify the issue type (mechanical, electrical, or surface).

-

For mechanical problems, check alignment, rollers, and hinges. Adjust with precision tools.

-

For electrical problems, inspect wiring, control panel settings, and sensor calibration.

-

Replace worn components immediately to avoid further damage.

Availability of spare parts is crucial. Reliable manufacturers maintain stocks of:

| Component | Typical Lifespan | Replacement Frequency | Notes |

|---|---|---|---|

| Rollers & Tracks | 3–5 years | As needed | Affects smooth sliding |

| Door Motors | 10–15 years | Rare, mostly under warranty | Ensure motor power matches door size |

| Sensors & Control Panels | 5–10 years | As needed | Prevents misfires and safety issues |

| Stainless Steel Panels | 20+ years | Rare | Check finish for scratches during operation |

Manufacturers often provide training or manuals for on-site maintenance, helping facility managers handle minor issues independently. For example, a commercial building in Dubai avoided extended elevator downtime by having replacement rollers and motors on hand, reducing repair time to under 24 hours.

See how we deliver reliable, code-compliant lifts—browse our elevator door solutions with PVD finish and global warranty.