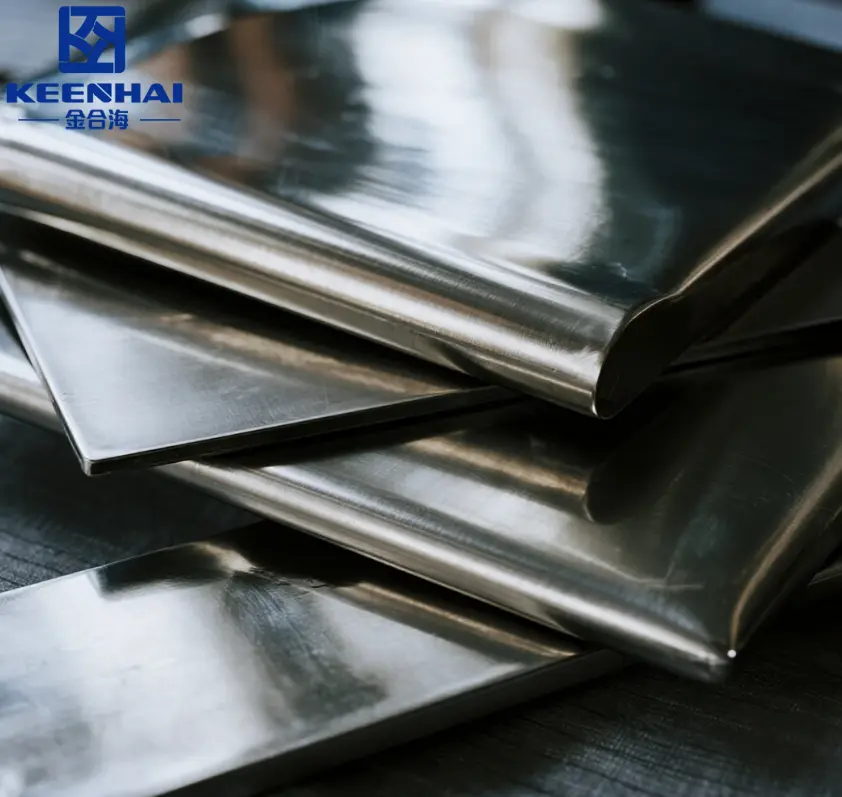

Ang usa ka PVD nga stainless steel sheet kay stainless steel nga adunay sapaw nga manipis, durable nga metal-nitride o metal-carbide layer nga gipadapat sa Physical Vapor Deposition, nga naghatag niini nga adunahan, dugay nga kolor ug labaw nga scratch ug corrosion resistance.

Kahulugan ug Kinauyokan nga mga Feature sa PVD Stainless Steel Sheets

Unsa ang Kahulogan sa "PVD" sa Stainless Steel?

PVD, mubo alang sa Pisikal nga Pagdeposito sa Singaw, usa ka proseso sa vacuum coating diin ang nipis nga mga pelikula sa materyal anaa pisikal nga gibutang sa usa ka stainless steel sheet ibabaw pinaagi sa vaporization. Dili sama sa tradisyonal nga pagpintal o electroplating, ang PVD nagbag-o sa solidong metal ngadto sa alisngaw ug dayon balik sa solidong porma sa sheet, nga naghimo sa usa ka labi ka lig-on ug pangdekorasyon nga pagkahuman. Kini nga advanced nga teknolohiya nagresulta sa usa ka layer sa ibabaw nga dili lamang nindot tan-awon apan usab labaw kaayo sa scratch resistance, corrosion resistance, ug color consistency.

A PVD stainless steel sheet sa pagkatinuod usa ka taas nga grado stainless steel sheet nga nakaagi niining proseso sa pagdeposito sa alisngaw, nga naghatag niini og mas maayo nga paghuman nga makasundog sa dagway sa bulawan, bronse, itom, rosas nga bulawan, o naandang mga kolor. Ang katig-a sa nawong human sa PVD coating kasagaran moabot sa 2500-3000 HV (Vickers Hardness), nga mao ang kamahinungdanon mas lisud kon itandi sa non-coated stainless steel, nga aberids sa palibot 200 HV.

Pangunang Kinaiya nga Naglainlain sa mga PVD Sheet gikan sa Regular nga Stainless Steel

Kung itandi ang a PVD coated stainless steel sheet sa usa ka regular nga stainless steel sheet, daghang lahi nga mga kalainan ang makita dayon sa pasundayag ug hitsura.

| Feature | PVD Stainless Steel Sheet | Regular nga Stainless Steel Sheet |

|---|---|---|

| Katig-a sa nawong | 2500-3000 HP | 180-220 HV |

| Corrosion Resistance | Maayo kaayo (Salt Spray> 72 ka oras) | Kasarangan (Salt Spray ~24 ka oras) |

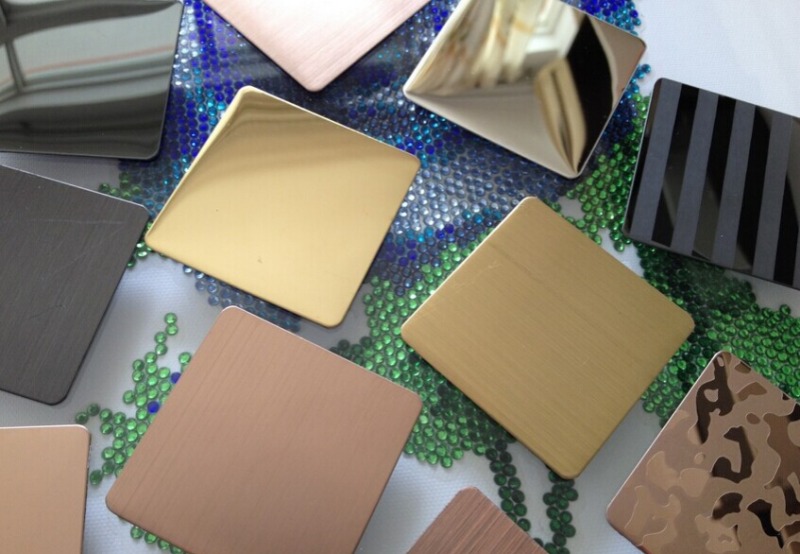

| Mga Opsyon sa Kolor | Lapad nga range (Gold, Black, Rose Gold, etc.) | Limitado (Natural nga Kolor nga Asero) |

| Scratch Resistance | Very High | Moderate |

| Panagsama sa nawong | Sama sa salamin nga katukma | Mahimong adunay makita nga mga pagkadili hingpit |

| Maintenance Frequency | Ubos | Medium |

| Gasto kada metro kwadrado | $50 – $120 | $20 – $40 |

Usa sa labing bililhon nga mga bentaha sa PVD stainless steel sheets mao ang ilang abilidad sa pagpadayon sa tin-aw, uniporme nga kolor bisan sa gawas nga palibot, diin ang UV radiation ug humidity kasagarang makadaot sa tradisyonal nga mga coating. Gipakita kana sa mga pagtuon Ang paghuman sa PVD nagpabiling sobra sa 90% sa ilang orihinal nga kahayag human sa lima ka tuig nga pagkaladlad sa gawas, samtang ang gipintalan o electroplated nga mga ibabaw mawad-an hangtod sa 40% sulod sa duha ka tuig.

Dugang sa durability, PVD stainless steel sheets tanyag a maluho nga paghuman nga nagpauswag sa mga aesthetics sa arkitektura, nga naghimo kanila nga usa ka nag-unang kapilian alang sa mga aplikasyon sama sa mga panel sa elevator, lobby sa hotel, ug mga muwebles nga tigdesinyo. Ang salamin finish nga nakab-ot pinaagi sa PVD mao ang biswal nga walay depekto, nga naghatag sa usa ka giladmon ug kadato nga dili makab-ot sa standard nga stainless steel.

Dugang pa, ang Ang epekto sa kalikopan sa PVD coating labi ka ubos itandi sa chemical plating, tungod kay dili kini makagama ug peligrosong basura. Ang proseso naggamit lamang sa 20%-30% sa enerhiya nga gigamit sa tradisyonal nga mga pamaagi sa electroplating, nga naghimo niini nga pareho. eco-friendly ug cost-effective sa dinagkong produksyon.

Para sa mga nangita ug kombinasyon sa visual excellence ug long-term performance, a PVD stainless steel sheet dili hitupngan sa merkado. Samtang ang gasto sa pag-una mahimong mas taas, ang pagkunhod sa pagmentinar, mas taas nga kinabuhi, ug labaw nga visual appeal paghatag og usa ka maayo kaayo nga pagbalik sa pamuhunan, ilabi na sa high-end nga arkitektura ug komersyal nga mga proyekto.

Ang pagsabut niini nga mga kinauyokan nga mga kinaiya hinungdanon kung magdesisyon kung mopili ba sa usa ka PVD stainless steel sheet labaw sa standard nga stainless steel, ilabi na sa mga proyekto diin ang aesthetics ug durability dili ma-negotiable.

Giunsa Pag-apply ang PVD Coating sa mga Stainless Steel Sheet

Overview sa Proseso sa Physical Vapor Deposition (PVD).

Ang Physical Vapor Deposition (PVD) Ang proseso nagbag-o sa usa ka patag stainless steel sheet ngadto sa usa ka premium, kolor nga nawong pinaagi sa pagdeposito sa nipis nga mga layer sa metal sa usa ka vacuum nga palibot. Ang proseso mahitabo sa sulod sa usa ka silyado nga lawak diin ang presyur moubos sa palibot 10^-5 hangtod 10^-7 Torr, paghimo sa usa ka hapit-hingpit nga vacuum. Kining ubos nga presyur nga palibot nagwagtang sa mga kontaminante ug nagtugot sa mga alisngaw nga mga atomo nga makabiyahe nga gawasnon ug mopahimutang sa ibabaw sa stainless steel sheet.

Ania kung giunsa ang PVD coating kasagarang gibuklad sa praktikal nga mga lakang:

-

Ang stainless steel sheet moagi sa bug-os nga pagpanglimpyo aron matangtang ang mga lana, hugaw, ug mga hugaw nga makaapekto sa coating adhesion.

-

Ang sheet gibutang sa sulod sa vacuum chamber, ug ang atmospera gibakwit.

-

Ang mga target nga materyales sama sa titanium, zirconium, o chromium gipainit ug gipaalisngaw gamit high-powered electron beams o magnetron sputtering, nga nagmugna og metal nga alisngaw nga panganod.

-

Kini nga alisngaw mo-condensate sa atomo pinaagi sa atom ngadto sa ibabaw sa sheet, nga nagporma sa usa ka ultra-nipis, kaayo uniporme nga metallic coating.

-

Ang mga parameter sa proseso sama sa temperatura (kasagaran 300–500°C), deposition rate (mga 10-20 nanometer kada minuto), ug ang presyur sa lawak tukma nga kontrolado aron maseguro ang labing maayo nga kalidad sa coating.

Ang tibuok PVD cycle alang sa usa ka batch mahimong molungtad bisan asa gikan 30 minutos ngadto sa 2 ka oras, depende sa gibag-on sa coating ug sa matang sa finish nga gitinguha. Ang proseso nagpatunghag mga sapaw gikan sa 0.1 hangtod 10 microns ang gibag-on, igo nga gibag-on aron mapalambo ang kalig-on nga dili ikompromiso ang pagka-flexible o gibug-aton sa PVD stainless steel sheet.

Mga Materyal ug Teknik nga Gigamit sa PVD Coating para sa Sheet

Ang pagpili sa husto nga coating nga materyal adunay hinungdanon nga papel sa pagtino sa katapusan nga hitsura ug pasundayag sa PVD stainless steel sheet. Ang kasagarang mga materyales naglakip sa:

-

Titanium Nitride (TiN): Nagtanyag usa ka mahayag nga kolor nga bulawan, talagsaon nga katig-a hangtod sa 2500 HP, ug maayo kaayo nga pagsukol sa kaagnasan.

-

Zirconium Nitride (ZrN): Naghimo usa ka mainit nga bulawan o bronse nga kolor, nga adunay taas nga pagsukol sa pagsul-ob ug kalig-on sa kemikal.

-

Chromium Nitride (CrN): Naghatag usa ka silver-gray o gunmetal nga paghuman, gipaboran alang sa mga anti-corrosive nga kabtangan ug kalig-on niini.

-

Titanium Carbonitride (TiCN): Nailhan tungod sa usa ka asul-abohon nga kolor ug grabe nga katig-a, nga sagad gigamit diin ang pagsukol sa pagsul-ob kritikal.

Ang mga teknik sa paggamit niini nga mga materyal lain-laing nag-una sa taliwala sa pag-sputter sa magnetron ug electron beam evaporation. Ang Magnetron sputtering popular tungod sa abilidad niini sa pagprodyus og mga dasok, adherent nga mga pelikula nga adunay taas nga pagkaparehas sa mas ubos nga gasto ug konsumo sa kuryente kon itandi sa mga pamaagi sa electron beam.

| Patong nga Materyal | Tipikal nga Kolor | Katig-a (HV) | Corrosion Resistance | Kasagaran nga Gibag-on sa Coating (microns) | Epekto sa Gasto kada Sq. Meter (USD) |

|---|---|---|---|---|---|

| Titanium Nitride (TiN) | Mahayag nga Bulawan | 2500 | Taas | 2-5 | 70-110 |

| Zirconium Nitride (ZrN) | Mainit nga Bulawan/Bronze | 2300 | Very High | 1-4 | 65-100 |

| Chromium Nitride (CrN) | Pilak/Gunmetal | 2000 | Very High | 1-3 | 60-90 |

| Titanium Carbonitride (TiCN) | Asul-Abohon | 2800 | Taas | 1-5 | 80-120 |

Ang kaepektibo sa proseso sa PVD nagdepende pag-ayo sa gahum sa kagamitan ug kalidad sa vacuum. Pananglitan, ang magnetron sputtering system kasagarang naglihok sa 1-5 kW nga lebel sa kuryente, pagbalanse tali sa katulin sa deposition ug density sa pelikula. Ang konsumo sa enerhiya kada metro kwadrado kay palibot 3-7 kWh, nga mas ubos kay sa tradisyonal nga mga pamaagi sa electroplating.

Ang mga operator nag-fine-tune sa mga parameter sama sa gas composition (kasagaran argon ug nitrogen), substrate rotation speed (10-20 rpm), ug chamber temperature aron makagama og mga coating nga magkombinar sa color stability, mechanical strength, ug adhesion. Kini nga katukma nagsiguro uniporme nga mga sapaw nga walay pagkausab sa kolor o pagpanit, pagpalugway sa magamit nga kinabuhi sa PVD stainless steel sheet lapas pa 10 ka tuig ubos sa normal nga kahimtang sa kinaiyahan.

Ang proseso sa coating sa PVD mibiya sa stainless steel sheet nga adunay usa ka finish nga mosukol sa pagsul-ob, kaagnasan, ug pagkalawos, nga naghimo niini nga sulundon alang sa lisud nga mga aplikasyon. Gigamit usab niini ang mas gamay nga mga kemikal ug naghimo og gamay nga basura, nga nahiuyon sa mga modernong regulasyon sa kinaiyahan ug mga katuyoan sa pagpadayon.

Kini nga cutting-edge nga teknolohiya sa coating nagtugot sa mga tiggama sa paghalad sa customized nga mga paghuman sa kolor ug pagpalambo sa performance, nga naghimo sa PVD stainless steel sheet usa ka dili hitupngan nga solusyon alang sa high-end nga arkitektura ug industriyal nga gamit.

Unsaon Pagtimbang-timbang sa Kalidad sa PVD Colored Stainless Steel Sheets

Mga Pamaagi sa Pag-inspeksyon sa Biswal alang sa Pagkakonsistensya sa Kolor

Pag-evaluate sa color consistency sa a PVD stainless steel sheet magsugod sa usa ka detalyado nga biswal nga eksaminasyon ubos sa husto nga kahimtang sa suga. Ang pagkaparehas sa kolor nagpakita sa katukma sa proseso sa Physical Vapor Deposition ug direkta nga nakaimpluwensya sa aesthetic nga bili ug gitan-aw nga kalidad sa nahuman nga produkto.

Girekomenda sa mga eksperto ang paghimo sa mga inspeksyon sa usa ka kontrolado nga palibot nga adunay natural nga kahayag sa adlaw o full-spectrum nga artipisyal nga kahayag sa 5000–6500 Kelvin para malikayan ang color distortion. Atol sa inspeksyon, pangitaa pag-ayo ang:

-

Ang pagkaparehas sa kolor sa tibuuk nga nawong, walay mga patsa, mga streak, o mga spots nga nagpakita sa dili patas nga coating.

-

Ang lebel sa gloss ug reflectivity, nga kinahanglan magpabilin nga makanunayon; Ang mga pag-usab-usab mahimong magsugyot sa dili maayo nga pagkontrol sa deposition.

-

Sakop sa kilid ug eskina, tungod kay ang dili kompleto nga coating sagad mahitabo sa mga ngilit, nga makapakunhod sa corrosion resistance ug durability.

-

Ang mga depekto sa nawong sama sa mga pinhole, bula, o mga garas nga nagpaubos sa kinatibuk-ang kalidad ug kalig-on.

Ang usa ka kalidad nga PVD finish kinahanglan ipakita ubos sa 3 Delta E (ΔE) nga kalainan sa kolor kung gisukod gamit ang spectrophotometer sa lainlaing mga punto sa sheet. Ang mga kantidad sa Delta E nag-ihap sa mga kalainan sa kolor nga gitan-aw sa tawo, nga adunay bisan unsang butang nga ubos sa 3 nga nagpakita nga halos dili makita nga mga kalainan. Kini nga sumbanan nagsiguro nga ang mga kustomer makadawat usa ka biswal nga wala’y sayup nga produkto nga sulundon alang sa mga aplikasyon sa arkitektura o pangdekorasyon.

Sa kasukwahi, ang mas barato o mas ubos nga kalidad nga mga coating sagad anaa Ang mga kantidad sa ΔE labaw sa 5, nagsenyas sa dili managsama nga kolor nga mahimong paspas nga madaot ubos sa mga stress sa kinaiyahan.

Pag-verify sa Gibag-on sa Coating ug Adhesion Standards

Ang gibag-on ug adhesion nagrepresentar sa duha sa labing kritikal nga mga parametro aron mahibal-an ang functional longevity sa a PVD stainless steel sheet. Ang patong nga nipis kaayo peligroso nga dali nga masul-ob, samtang ang sobra nga gibag-on mahimong hinungdan sa pagliki o pagpanit.

Ang pagsulay sa gibag-on sa coating kasagaran naglakip dili makadaut nga mga teknik sa pagsukod sama sa magnetic induction o eddy current gauge. Ang mga sumbanan sa industriya nagreseta sa gibag-on tali sa taliwala 1 hangtod 5 microns alang sa pangdekorasyon nga mga aplikasyon ug hangtod sa 10 microns alang sa bug-at nga katungdanan nga paggamit. Ang makanunayon nga gibag-on sa tibuuk nga sheet hinungdanon, nga adunay madawat nga pagbag-o nga sagad gitipigan sa sulod ± 0.2 microns.

Ang kalig-on sa adhesion nagtino kung unsa ka maayo ang PVD coating bond sa ilawom nga bahin sa metal. Usa ka kaylap nga gidawat nga pagsulay mao ang cross-cut adhesion test (ISO 2409), diin ang usa ka pattern sa lattice giputol sa coating, ug ang adhesive tape gipadapat ug gikuha aron masusi kung ang mga flakes o chips natangtang. Grade 0 hangtod 1 sa kini nga sukod nagpasabut nga gamay hangtod wala’y pagkawala sa coating, usa ka sukaranan alang sa mga premium nga kalidad nga mga sheet.

Ang ubang mga advanced nga pamaagi naglakip sa:

-

Pull-off nga pagsulay, pagsukod sa puwersa nga gikinahanglan sa pagtangtang sa taklap.

-

Pagsulay sa pagsukol sa scratch, pag-ihap sa pagsukol sa coating sa deformation ubos sa kusog, kasagaran sobra 3000 HV katig-a.

| Parameter | Tipikal nga Range | Sumbanan/Paagi sa Industriya | Kahinungdanon |

|---|---|---|---|

| Gibag-on sa coating | 1-5 microns (dekorasyon) / hangtod sa 10 microns (bug-at nga katungdanan) | Magnetic induction / Eddy nga kasamtangan | Makaapektar sa durability ug finish |

| Pagkaparehas sa gibag-on | ± 0.2 microns | Gisukod sa daghang mga punto sa ibabaw | Gipugngan ang mga huyang nga lugar |

| Grado sa Adhesion | 0-1 (ISO 2409 scale) | Pagsulay sa cross-cut adhesion | Gisiguro ang taas nga kinabuhi sa coating |

| Katig-a | 2500-3000 HP | Pagsulay sa micro-scratch | Pagbatok sa pagsul-ob ug mga garas |

Ang kalig-on sa coating direkta nga nakaapekto sa gasto sa pagmentinar ug gitas-on sa kinabuhi. Taas nga kalidad PVD stainless steel sheets kasagaran manghambog sa mga kinabuhi sa pag-alagad sa unahan 10 years nga walay mahinungdanon nga pagkadaut sa integridad sa coating o pagkamatinud-anon sa kolor, nga naghimo kanila nga usa ka cost-effective nga solusyon sa kadugayan bisan pa sa mas taas nga presyo sa unahan.

Sa katapusan, ang mga pumapalit kinahanglan kanunay nga mangayo mga taho sa pagsulay o sertipikasyon gikan sa mga supplier nga nagpamatuod niini nga mga parameter aron malikayan ang mga substandard nga mga produkto nga mahimong mosangput sa mahal nga mga kapuli o kadaot sa reputasyon sa ilang mga proyekto.

Mga Online nga Platform ug Marketplaces alang sa Kasaligang mga Pagpamalit

Girekomenda nga mga Platform sa E-commerce alang sa mga Mamalitay sa Industriya

Alang sa mga pumapalit sa industriya nga nangita alang sa taas nga kalidad PVD stainless steel sheet. Daghang mga platform sa B2B ang mitumaw isip mga lider sa industriya pinaagi sa pagtanyag sa mga napamatud-an nga mga supplier, detalyado nga mga detalye sa produkto, ug mga kapilian sa pagpadala sa kalibutan.

Lakip sa mga top platform mao ang Alibaba, Made-in-China, ug Mga Tinubdan sa Kalibutan. Kini nga mga plataporma nag-host sa libu-libo nga mga listahan sa produkto nga stainless steel, lakip ang PVD coated sheets, nga adunay mga kapilian gikan sa gagmay nga mga order sa batch hangtod sa daghang gidaghanon sa industriya. Ang Alibaba nag-inusara nga mga bahin sa ibabaw 5,000 ka stainless steel sheet suppliers, daghan nga nag-espesyalisar sa PVD finishes.

Ang panguna nga mga bentaha sa kini nga mga platform naglakip sa:

-

Sistema sa Pagpamatuod sa Supplier: Kadaghanan sa mga inila nga mga merkado nagpatuman sa daghang lebel nga pag-verify, lakip ang mga pag-audit sa pabrika ug mga pagsusi sa kalidad sa produkto, nga nagpakunhod sa peligro sa pagpanglimbong.

-

Detalyadong Katalogo sa Produkto: Ang mga lista kanunay adunay komprehensibo nga teknikal nga datos sama sa gibag-on sa coating, katig-a, mga rating sa resistensya sa kaagnasan, ug magamit nga mga kapilian sa kolor.

-

Mga Review ug Rating sa Customer: Ang mga pumapalit mahimong magtimbang-timbang sa kasaligan sa supplier base sa feedback ug kasaysayan sa transaksyon.

-

Flexible nga Pagbayad ug Mga Termino sa Pagpadala: Gisuportahan sa mga plataporma ang lainlaing mga pamaagi sa pagbayad, nga adunay mga kapilian alang sa kasiguruhan sa pamatigayon ug mga serbisyo sa escrow, pagsiguro nga luwas ang mga transaksyon.

Ang presyo sa kini nga mga plataporma mahimong magkalainlain base sa klase sa coating, gibag-on, mga sukat sa sheet, ug gidaghanon sa order. Pananglitan, a standard 304 stainless steel sheet nga adunay PVD coating mahimong gasto tali sa $70 ug $120 kada metro kwadrado, samtang ang mas taas nga grado nga mga haluang metal o espesyal nga mga kolor nagmando sa mga premium nga presyo.

Unsaon Paglikay sa Ubos nga Kalidad o Peke nga mga Produkto sa PVD Online

Ang pagpalit sa PVD stainless steel sheets online nagdala sa mga kinaiyanhon nga mga risgo nga may kalabutan sa pagkakasaligan sa produkto ug kalidad sa coating. Ang mga peke o substandard nga mga produkto kasagaran adunay dili maayo nga pagkaporma sa kolor, nipis nga mga coating, ug kakulang sa kalig-on, nga mosangpot sa ahat nga pagsul-ob ug mahal nga mga kapuli.

Ang mga pumapalit kinahanglan nga magpatuman sa daghang mga estratehiya aron malikayan kini nga mga lit-ag:

-

Paghangyo sa Detalyado nga Mga Sertipikasyon sa Produkto: Siguruha nga ang mga supplier naghatag mga dokumentasyon sama sa Sertipikasyon sa kalidad sa ISO 9001, paghubit sa proseso sa coating, ug mga report sa pagsulay sa ikatulo nga partido nga nagpamatuod sa gibag-on sa coating ug adhesion.

-

Pangayo ug Pisikal nga Sampol: Ang usa ka pisikal nga sample nagtugot sa biswal nga inspeksyon alang sa pagkaparehas sa kolor ug paghuman sa nawong, ingon man ang pagsulay sa laboratoryo alang sa mga parameter sa coating.

-

Timbang-timbanga ang Transparency sa Supplier: Ang tinuod nga mga suppliers dayag nga nagpaambit sa mga detalye sa paggama ug nagmintinar sa responsive nga mga channel sa komunikasyon.

-

I-verify ang mga Imahe ug Video sa Produkto: Susiha ang high-resolution nga media nga nagpakita sa coating uniformity ug edge coverage.

-

Cross-Check nga Presyo: Ubos kaayo nga mga presyo kon itandi sa mga aberids sa industriya (kasagaran ubos pa kay sa $50 kada metro kwadrado para sa dekalidad nga PVD sheets) kasagarang magsenyas sa ubos nga kalidad o imitasyon nga mga produkto.

-

Gamita ang Platform Trade Assurance: Pagpili alang sa mga merkado nga nagtanyag og panalipod sa pumapalit aron mamenosan ang mga risgo sa pagpanglimbong o pagkalangan sa pagpadala.

| Risk Factor | Timailhan sa Pulang Bandila | Girekomenda nga Aksyon |

|---|---|---|

| Kakulang sa Sertipikasyon | Ang supplier dili makahatag ug kalidad nga mga taho | Paghangyo ug mga sertipiko sa pagsulay sa ikatulo nga partido |

| Dili makanunayon nga Produkto Media | Ubos nga kalidad o stock nga mga imahe/video | Pangayo ug tinuod nga mga sample ug inspeksyon |

| Kadudahang Ubos nga Presyo | Presyo ubos sa $50 kada sqm alang sa PVD coated sheets | Itandi sa mga average sa merkado |

| Dili Maayo nga Komunikasyon | Nalangan o dili klaro nga mga tubag sa supplier | Pilia ang mga supplier nga adunay lig-on nga feedback |

Ang pasiuna nga paningkamot sa pag-verify sa kredibilidad sa supplier nagbayad pinaagi sa pagsiguro sa tinuod PVD stainless steel sheet mga produkto nga adunay matag-an nga pasundayag ug taas nga kinabuhi. Ang kasaligang sourcing makapamenos sa downtime, gasto sa pagmentinar, ug posibleng mga risgo sa reputasyon alang sa mga proyektong pang-industriya nga nanginahanglan og durable ug aesthetically refined nga mga materyales.

May kalabotan: Mga benepisyo sa pagpili sa PVD stainless steel sheet