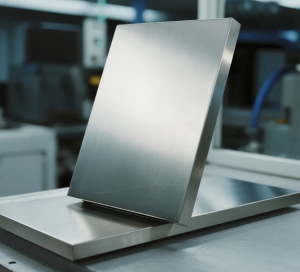

Panel z nerezové oceli vs. hliník: Který panel dominuje v odolnosti? Ponořte se do dokonalého souboje – podívejte se, jak si vedou v reálném používání, od koroze až po dlouhodobé opotřebení.

Co odlišuje nerezovou ocel a hliník

rudní rozdíly mezi nerezovou ocelí a hliníkem

Nerezová ocel a hliník vynikají jako dva nejpoužívanější kovy ve výrobě, ale jejich vnitřní vlastnosti vytvářejí zřetelné výhody v trvanlivosti. Pochopení těchto rozdílů je klíčem k výběru správného materiálu pro vysoce výkonné aplikace, jako jsou poštovní schránky, průmyslové panely a zakázkové komponenty.

Chemické složení

Nerezová ocel je slitina složená převážně ze železa, chromu (alespoň 10,5%) a často niklu, manganu nebo molybdenu. Toto složení tvoří pasivní vrstvu oxid chromu vrstvu na povrchu, která odolává korozi. Hliník je naproti tomu čistý kov (se stopovými prvky), který přirozeně tvoří tenkou Aluminvůlnápad vrstva, která nabízí vlastní formu ochrany.

Fyzikální vlastnosti

|

Property

|

Nerez

|

Aluminum

|

|

Hustota

|

Vyšší (7,9 g/cm³)

|

Nižší (2,7 g/cm³)

|

|

Strength

|

Vyšší pevnost v tahu, ideální pro vysoké zatížení

|

Nižší pevnost v tahu, lepší pro lehké konstrukce

|

|

Tepelná odolnost

|

Odolává vyšším teplotám (až 870 °C)

|

Ztrácí pevnost při vysokých teplotách (nad 200 °C)

|

|

Kujnost

|

Méně tvárný, vyžaduje větší sílu k tvarování

|

Vysoce tvárný, snadno se tvaruje do složitých vzorů

|

Odolnost proti korozi

Díky obsahu chromu je nerezová ocel vysoce odolná vůči rzi a korozi, a to i ve vlhkém nebo chemicky vystaveném prostředí. Tato odolnost je zvýšena u produktů, jako je PVD nerezová ocel, kde fyzikální napařování (PVD) přidává další ochrannou vrstvu. Vrstva oxidu hliníku poskytuje dobrou odolnost proti korozi za mírných podmínek, ale může se degradovat v kyselém nebo alkalickém prostředí bez dalších povlaků.

Dlouhodobá trvanlivost

Nerezová ocel si zachovává strukturální integritu po celá desetiletí, takže je vhodná pro venkovní nebo často používané výrobky, jako jsou poštovní schránky, které jsou neustále vystaveny povětrnostním vlivům. Hliník je sice odolný, ale při intenzivním používání nebo extrémních podmínkách může vykazovat známky opotřebení rychleji, což vyžaduje častější údržbu nebo výměnu.

PVD povlak: odolná hrana PVD nerezové oceli

Jak PVD povlak zvyšuje trvanlivost nerezové oceli

PVD (fyzikální depozice z plynné fáze) mění vlastnosti nerezové oceli, díky čemuž je PVD nerezová ocel vynikající volbou pro odolné aplikace. Tento pokročilý proces vytváří vazbu mezi povlakem a základním kovem, která překonává tradiční lakování nebo pokovování a přímo řeší klíčové problémy s trvanlivostí.

Věda, která stojí za PVD povlakováním

PVD funguje na principu odpařování pevných materiálů (jako je titan nebo chrom) ve vakuové komoře a jejich nanášení na povrch nerezové oceli jako tenká, rovnoměrná vrstva. Na rozdíl od povlaků na bázi kapalin se tato metoda vyhýbá pórům nebo nerovnostem a zajišťuje plné pokrytí. Výsledkem je povlak, který splývá s ocelí na molekulární úrovni a je odolný vůči odlupování, loupání nebo opotřebení. Tato technika je v souladu s moderními... surfacjedenineering principy, upřednostňující dlouhodobou adhezi.

Klíčové výhody pro odolnost

- Zvýšená odolnost proti koroziPVD vrstva působí jako bariéra proti vlhkosti, soli a chemikáliím – běžným hrozbám pro trvanlivost kovu. V kombinaci s přírodní vrstvou oxidu chromu z nerezové oceli vytváří dvojitý obranný systém, ideální pro venkovní poštovní schránky nebo pobřežní aplikace.

- Odolnost proti poškrábání a oděruPVD povlaky se řadí na přední místa Mach hArdness scpivo, často přesahující 8. Tato tvrdost zabraňuje poškození povrchu při každodenním používání, takže výrobky z nerezové oceli PVD vypadají jako nové i po letech manipulace.

- Zachování barevNa rozdíl od lakovaných povrchů, které pod vlivem UV záření blednou, si PVD povlaky zachovávají barevnou stálost. Díky tomu jsou ideální pro dekorativní prvky, kde je estetika stejně důležitá jako funkčnost, jako například pro panely poštovních schránek s vlastním vzorem.

- Teplotní toleranceNerezová ocel s PVD povlakem odolává extrémním teplotám bez degradace, což je klíčová vlastnost pro průmyslové prostředí nebo venkovní prostředí s náročnými povětrnostními výkyvy.

Proč vyniká nerezová ocel PVD

Integrací PVD povlaku do výroby spojují výrobky z nerezové oceli pvdstainlesssteel trvanlivost a všestrannost. Povlak doplňuje inherentní pevnost nerezové oceli a mění ji v materiál, který odolává jak času, tak i vlivům prostředí. Ať už se jedná o průmyslové panely s vysokou frekvencí provozu nebo dekorativní poštovní schránky, tato kombinace zajišťuje dlouhou životnost bez obětování flexibility designu.

Měřítka kvality: ISO9001, PPG, KYNAR500

Jak kritéria kvality zvyšují odolnost v každé fázi

Normy kvality, jako jsou ISO9001, PPG a KYNAR500, dělají více než jen stanovování standardů – zakotvují odolnost v každém aspektu výroby nerezové oceli. U nerezové oceli PVD tyto normy fungují jako zábradlí, které zajišťuje, že každý produkt, od suroviny až po hotový výrobek, splňuje přísná kritéria, která se přímo promítají do delší životnosti a lepšího výkonu.

ISO9001:2008 – Od surovin až po hotové výrobky

Norma ISO9001:2008 nařizuje přísnou sledovatelnost, což znamená, že technologie PVD Stainlesssteel sleduje každou šarži oceli od dodavatelů až po finální produkt. Uliceainless Stúhoř PanelTato sledovatelnost umožňuje rychlou identifikaci jakýchkoli nesrovnalostí materiálu, které by mohly snížit trvanlivost. Norma také vyžaduje pravidelné školení personálu, aby se zajistilo, že obsluha bude přesně zacházet se zařízením pro PVD povlakování – což je zásadní pro rovnoměrné nanášení vrstvy, které zabraňuje vzniku korozních ohnisek. Auditoři podle normy ISO 9001:2008 kontrolují nejen hotové výrobky, ale také skladovací podmínky a zajišťují, aby ocelové panely před povlakováním nerezavěly, což je detail, který zachovává jejich integritu.

PPG Coatings – Více než základní ochrana

Povlaky PPG procházejí přísnými testy, aby se zajistilo bezproblémové spojení s povrchem nerezové oceli PVD. Jejich složení obsahuje inhibitory koroze, které se aktivují při vystavení vlhkosti a vytvářejí aktivní ochranu proti korozi. Pro venkovní použití Skvrnaméně Ocel Podoknol V různých aplikacích zabraňují UV odolné přísady PPG křídování – běžnému problému, kdy se nátěry pod slunečním zářením rozpadají na prášek. Tato odolnost znamená, že panely si zachovávají svou ochrannou vrstvu i po letech přímého vystavení, což snižuje potřebu opětovného nátěru. PPG také nabízí zakázkové složení pro nerezovou ocel s PVD povrchovou úpravou, přizpůsobené specifickým prostředím, jako jsou průmyslové zóny s vysokou chemickou expozicí.

KYNAR500 – Inženýrství pro desetiletí používání

Pryskyřičná struktura PVDF materiálu KYNAR500 vytváří povlak, který se při teplotních výkyvech roztahuje a smršťuje spolu s nerezovou ocelí, čímž zabraňuje vzniku trhlin, které by mohly pronikat dovnitř vlhkostí. Tato flexibilita je zásadní pro... pvdstainlesssteel prprodukts v oblastech s extrémním chladem nebo horkem. Testy ukazují, že si povlaky KYNAR500 zachovávají více než 90% své barvy a lesku i po 20 letech venkovního vystavení, což výrazně překonává akrylové nebo epoxidové alternativy. U pobřežních projektů KYNAR500 odolává korozi v solné mlze, což je klíčová výhoda pro poštovní schránky z nerezové oceli PVD nebo panely v blízkosti oceánů, kde vzduch nasycený solí může degradovat nechráněný kov během měsíců.

Synergie mezi benchmarky – ekosystém trvanlivosti

Norma ISO 9001:2008 zajišťuje správnou aplikaci povlaků PPG a KYNAR500 s dokumentovanými postupy pro kontrolu tloušťky a testy adheze. Povlaky PPG připravují povrch nerezové oceli, díky čemuž KYNAR500 lépe přilne – což je dvojnásobná výhoda v boji proti korozi. Tato kritéria společně vytvářejí systém, kde výrobky z nerezové oceli PVD splňují nejen individuální metriky trvanlivosti, ale vynikají i v reálných podmínkách. Tento ekosystém je důvodem, proč architekti a výrobci důvěřují nerezové oceli PVD v projektech, kde dlouhá životnost není jen vlastností, ale požadavkem.

Trvanlivost v reálném světě: Poštovní schránky pro průmysl

Trvanlivost testovaná v různých prostředích

Nerezová ocel a hliník prokazují svou odolnost v řadě reálných scénářů, z nichž každý má jedinečné stresory, které oddělují materiály s krátkou životností od materiálů s dlouhou životností. Od obytných chodníků až po tovární haly se jejich výkonnostní rozdíly projeví každodenním opotřebením a neočekávanými výzvami.

Poštovní schránky: Pevnost v ročních obdobích i sabotážích

A Poštovní schránka z nerezové oceli Nerezová ocel z PVD čelí více než jen dešti a sněhu. V pobřežních městech denně bičují poštovní schránky větry zatížené solí – vrstva oxidu chromu z nerezové oceli tuto korozi bojuje, zatímco hliníkové poštovní schránky často do roka vytvoří důlkový povrch. V městských oblastech vandalismus testuje pevnost: nerezová ocel odolává promáčklinám od baseballových pálek nebo nárazům kopů, čímž udržuje poštovní schránku funkční. Majitelé domů v severních oblastech si všímají další výhody: nerezová ocel odolává opakovaným cyklům mrazu a tání bez praskání, na rozdíl od hliníku, který se může po 3–4 krutých zimách rozpadat ve svarových bodech. A Socasess Steel Poštovní schránkavůl z nerezové oceli s PVD povrchovou úpravou obvykle vydrží v těchto podmínkách více než 25 let, zatímco hliníkové modely v průměru vydrží 8–12 let, než je nutné je vyměnit.

Průmyslové aplikace: Odolnost proti neustálému zatěžování

Továrny, které běží nepřetržitě, vystavují kovové panely neúnavné zátěži. Panely z nerezové oceli v automobilových závodech odolávají každodennímu kontaktu s mastnými stroji a zachovávají si svůj povrch i po opakovaném otírání průmyslovými čisticími prostředky. Hliníkové panely ve stejném prostředí často během několika měsíců zmatní nebo se na nich objeví skvrny, což vyžaduje opětovné leštění. V chemických závodech nerezová ocel odolává rozlitým kyselinám a zásadám a zachovává si tak strukturální integritu. Hliník, pokud je vystaven těmto látkám, může při okamžitém vyčištění prokorodovat během několika týdnů. Pracovníci v balírnách preferují pracovní povrchy z nerezové oceli – odolávají poškrábání od ostrých nástrojů a zabraňují bakteriím, aby se ukrývaly v drážkách, což je problém, který trápí hliníkové povrchy v oblastech bezpečných pro potraviny.

Doprava a infrastruktura: Trvanlivost v pohybu a v čase

Systémy veřejné dopravy se spoléhají na materiály, které zvládají neustálý pohyb. Nerezová madla ve vozech metra vykazují po letech používání minimální opotřebení, zatímco hliníková zábradlí se stávají viditelnými škrábanci a promáčklinami, které zhoršují přilnavost. Mosty v zasněžených oblastech vyprávějí podobný příběh: nerezové spojovací prvky odolávají korozi způsobené posypovou solí a udržují konstrukční prvky v bezpečí, zatímco hliníkové spojovací prvky se často zadírají nebo zlomí, což vyžaduje nákladné opravy. Letiště používají nerezovou ocel v prostorách pro výdej zavazadel – její odolnost vůči promáčknutím od těžkých zavazadel překonává hliník, který se snadno promáčkne a vyžaduje častou výměnu panelů.

Zemědělské prostředí: Boj proti vlhkosti a chemikáliím

Mléčné farmy představují jedinečnou výzvu: vysokou vlhkost a pravidelné vystavení mléčným kyselinám. Nerezové nádrže na mléko zůstávají hladké a čisté, což zabraňuje růstu bakterií, zatímco hliníkové nádrže vytvářejí drsné skvrny, které zachycují zbytky, což vyžaduje každodenní drhnutí. Prostory pro skladování hnojiv testují odolnost proti korozi – nerezové nádoby odolávají sloučeninám bohatým na dusík, zatímco hliníkové nádoby se během 2–3 let prodírají, což vede k nákladným netěsnostem. Zemědělci také upozorňují na výhodu nerezové oceli při čištění: mytí tlakovou vodou nepoškozuje její povrch, na rozdíl od hliníku, který se může pod silným proudem vody deformovat.

Mořské prostředí: Boj se slanou vodou a vlhkostí

Součásti lodí a kování doků čelí neúnavnému vystavení slané vodě. Nerezové úchyty a zábradlí na lodích odolávají korozi i po letech v oceánu, zatímco hliníkové rychle korodují, stávají se křehkými a nebezpečnými. Chodníky v přístavech vyrobené z nerezové ocelové mřížky zůstávají protiskluzové, protože jejich povrch se nerozkládá na práškové zbytky – hliníková mřížka často vyžaduje každoroční ošetření, aby se tomuto poškození zabránilo. Rybáři dávají přednost nerezovým boxům na náčiní; odolávají vlhkému a slanému prostředí, aniž by se při zavírání rezavěly, což je běžný problém hliníkových boxů, které se po jediné sezóně zaseknou.

Přizpůsobení a dlouhotrvající výkon

Vyvážení mezi zakázkovým designem a odolností

Přizpůsobení nemusí obětovat dlouhou životnost – nerezová ocel, zejména s PVD povlakem, nabízí nekonečnou flexibilitu designu a zároveň si zachovává robustní výkon. Od jedinečných vzorů až po rozměry na míru, každý detail na míru může být v souladu s inherentní odolností materiálu, čímž vznikají produkty, které vypadají jedinečně a obstojí ve zkoušce času.

Vlastní rozměry: Bez kompromisů

Výrobci dokáží vyrobit panely a poštovní schránky z nerezové oceli na přesné rozměry, což zajišťuje perfektní přizpůsobení specifickým prostorům. Například komerční budova s nestandardními rozměry vstupu si může nechat vyrobit poštovní schránku z nerezové oceli na míru, která bezproblémově zapadne do architektury. Na rozdíl od hliníku, který se při řezání na neobvyklé rozměry může oslabit, si nerezová ocel zachovává svou pevnost i u složitých řezů nebo nepravidelných tvarů. To znamená, že nerezové komponenty na míru odolávají ohýbání nebo deformaci pod tlakem, ať už jsou součástí nástěnného panelu nebo volně stojící konstrukce.

Dekorativní vzory: Styl, který vydrží

Dekorativní vzory na míru, leptané nebo vyražené na nerezových površích, zvyšují vizuální atraktivitu, aniž by snižovaly odolnost. PVD povlak tyto vzory uzamyká a zabraňuje jejich vyblednutí nebo opotřebení. Například poštovní schránka s geometrickým designem na míru si zachová své ostré linie po mnoho let, a to i při každodenním používání. Hliník naopak často rychle ztrácí dekorativní detaily – leptání se může rozmazat korozí a malované vzory se odlupují, takže materiál je náchylný k dalšímu poškození. Díky zachování vzoru u nerezové oceli zůstávají zachovány jak estetika, tak i ochrana.

Kompatibilita s OEM: Přizpůsobeno potřebám průmyslu

Výrobci originálních zařízení (OEM) se při integraci se svými stroji spoléhají na zakázkové díly z nerezové oceli. Ať už se jedná o specializovaný držák pro průmyslové zařízení nebo panel na míru pro interiér vozidla, nerezová ocel se přizpůsobí přesným specifikacím. Její vysoká pevnost v tahu zajišťuje, že tyto zakázkové díly zvládnou provozní namáhání při zamýšleném použití, od vysokého zatížení až po neustálé vibrace. Hliník, i když je tvárný pro úpravy na míru, nemusí vydržet ve vysoce namáhaných aplikacích OEM, což vede k předčasnému selhání a nákladným výměnám.

Povrchové úpravy odolné vůči povětrnostním vlivům na zakázku

Na nerezovou ocel lze aplikovat zakázkové povrchové úpravy, od matných až po vysoce lesklé, aniž by se snížila její odolnost vůči povětrnostním vlivům. Například zakázková lesklá povrchová úprava venkovního panelu z nerezové oceli odpuzuje déšť a UV záření stejně účinně jako standardní povrchová úprava. PVD povlak tuto skutečnost umocňuje – dodává barevné odstíny nebo metalické odstíny, které odolávají blednutí i na přímém slunečním záření. To znamená, že zakázkové barvy na nerezové oceli si zachovávají svůj zářivý vzhled i v dešti, sněhu a intenzivním teple, čímž překonávají hliníkové alternativy, které se v drsném počasí často zbarvují nebo zmatní.