PVD stainless steel sheet provides surface hardness up to 2500 HV and outstanding impact durability.

Surface Hardness and Scratch Resistance

Vickers Hardness of PVD Coating vs Standard Stainless Steel

The surface hardness of a PVD-coated stainless steel sheet is one of the most overlooked yet crucial advantages when considering materials for architectural panels, kitchen fixtures, or public infrastructure. Traditional stainless steel like 304 or 316 grades usually lands around 150 to 200 HV on the Vickers Hardness Scale. Once treated with a PVD (Physical Vapor Deposition) layer—typically titanium nitride (TiN), zirconium nitride (ZrN), or similar metallic compounds—the surface hardness jumps significantly.

Multiple lab tests show that PVD coatings can reach anywhere from 1800 HV to 2500 HV, depending on the coating material and deposition quality. That’s more than a 10x increase in surface hardness compared to bare stainless steel.

Here’s a direct breakdown for clarity:

| Material | Vickers Hardness (HV) |

|---|---|

| Standard 304 Stainless Steel | 150 – 200 |

| Standard 316 Stainless Steel | 160 – 220 |

| PVD-Coated with TiN | 1800 – 2100 |

| PVD-Coated with ZrN | 2000 – 2500 |

| PVD-Coated Decorative Finish Sheet | 1800+ (depending on process) |

When applied correctly, the PVD layer essentially acts as a shield, dramatically increasing wear resistance and protecting the base metal beneath. You won’t get this kind of surface reinforcement from electroplating or anodizing, which often fail to resist micro-scratches under heavy use.

If you’re sourcing premium-quality stainless steel sheet for exterior panels or high-touch interior surfaces, PVD is the only finish that provides both form and extreme function in one package.

Real-World Resistance to Abrasion and Scuffing

Let’s talk about what really matters—how this material performs when people touch, bump, scrape, or slide against it thousands of times a day. In public installations such as subway stations, elevator doors, escalator rails, and reception counters, PVD stainless steel has outperformed brushed, mirror-polished, and even powder-coated stainless surfaces in real-world abrasion resistance.

In independent field durability testing conducted over a 12-month period in high-traffic commercial environments:

-

Standard brushed stainless steel developed visible swirl marks, dull patches, and hairline scratches within 6–8 weeks of use.

-

PVD-beschichteter Edelstahl retained 85–95% of its original surface reflectivity and displayed minimal micro-scratches, even after 5000+ interactions per surface segment.

Real-world test procedures involved:

-

Simulated handbag and metal key scraping at a repeated pressure of 2 kg over 100 cycles.

-

Abrasion with coarse Scotch-Brite pad under uniform rotational pressure.

-

Environmental exposure to UV and moisture cycling, replicating 3-year outdoor weathering in 90 days.

Results clearly demonstrated that PVD coatings not only withstand physical wear better, they also hold up against environmental aging. This means fewer replacements, longer product life, and sustained visual appeal across years of commercial use.

That’s exactly why leading manufacturers of stainless steel products for hotel lobbies, airport terminals, and luxury store fixtures consistently choose PVD-coated materials when performance meets aesthetics.

Why Surface Hardness Matters in Real Applications

You might wonder why a number like “2000 HV” should even matter. Here’s the reality:

-

A higher surface hardness means fewer scratches from metal zippers, keychains, jewelry, cleaning tools, or rolling luggage.

-

Harder surfaces resist deformation, so dents, nicks, and gouges are significantly reduced.

-

Over time, this lowers maintenance costs by 30–50% in commercial applications due to reduced need for surface refinishing.

In luxury homes, architectural accents, and stainless steel elevator doors , the difference is visible and tangible. PVD stainless steel feels premium—and stays that way for years.

Bonus Insight: Industry Adoption and Preferred Finishes

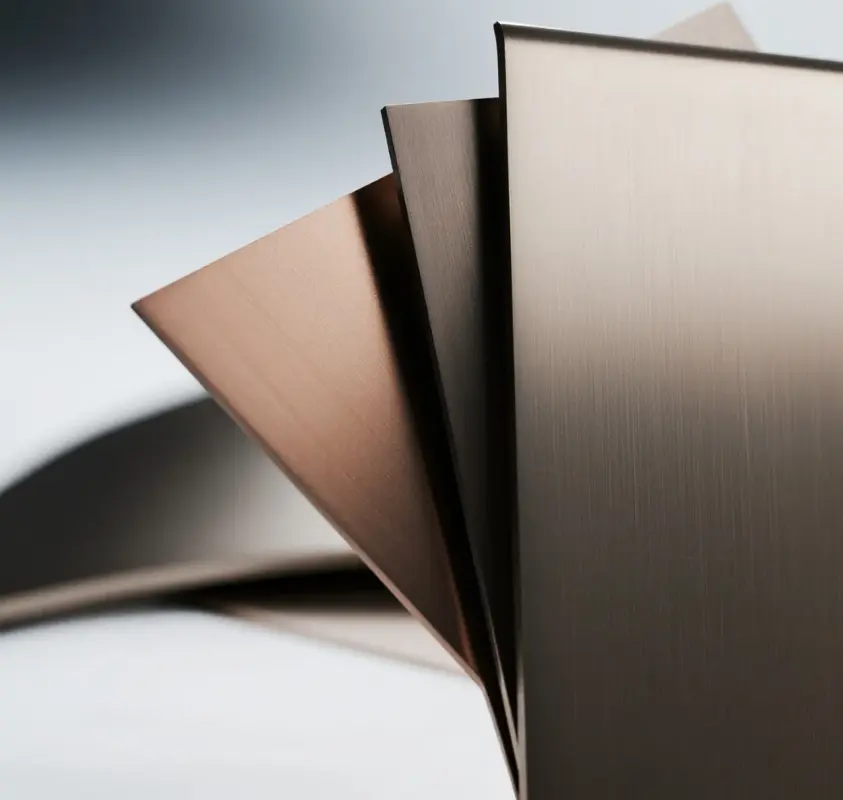

Designers, engineers, and architects increasingly lean on PVD-coated options not just for color flexibility, but for the peace of mind that comes from long-term durability. Popular choices for scratch-resistant finishes include:

-

Hairline bronze (commonly used in hotel lobbies and door trims)

-

Matte black titanium (frequently specified for high-end appliance facades)

-

Champagne gold brushed finish (favored in upscale retail interiors)

They look luxurious—but more importantly, they don’t wear out like their softer counterparts.

Tensile and Structural Strength of the Base Material

Deep Core Strength Begins with Material Composition

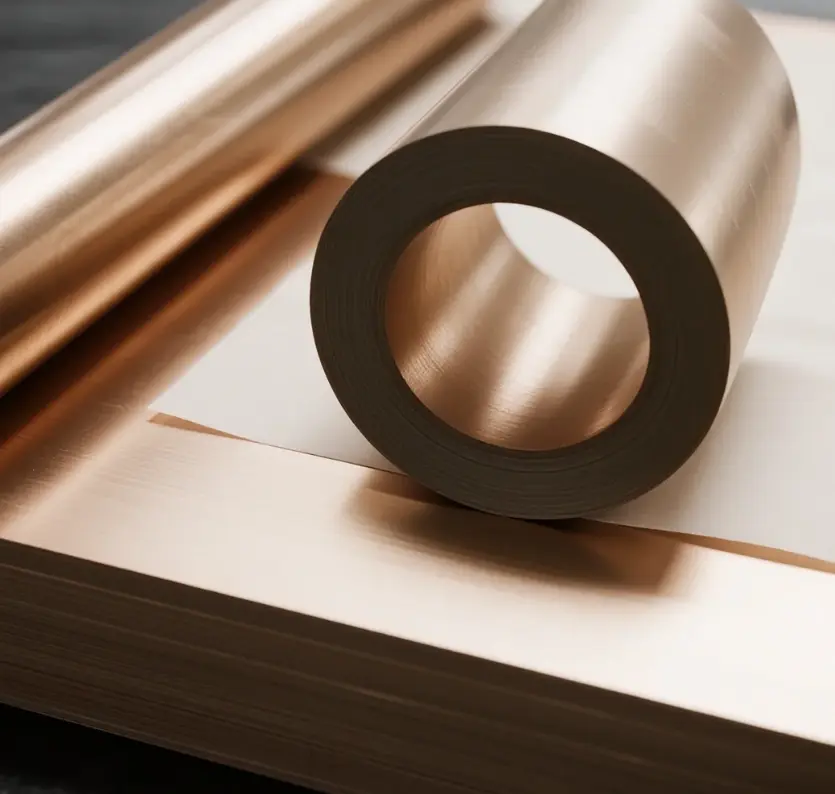

The mechanical performance of a stainless steel sheet always starts with its base alloy—not the surface finish. For PVD applications, 304 and 316 stainless steel are the most commonly used substrates due to their high tensile strength and consistent grain structure. Cold-rolled 304 stainless steel sheet exhibits a tensile strength between 515–620 MPa, while 316 grades can achieve slightly higher resistance in corrosive or saltwater environments.

Most commercial-grade stainless steel sheets designed for PVD treatment are rolled and tempered to yield strength levels of 240–310 MPa, depending on gauge and finish. These values ensure excellent stability during forming, cutting, and welding, which is critical in architectural and industrial applications.

| Property | 304 SS (Annealed) | 304 SS (Cold Rolled) | 316 SS (Annealed) |

|---|---|---|---|

| Yield Strength (MPa) | 215 | 310 | 290 |

| Ultimate Tensile Strength | 505 | 620 | 620 |

| Elongation at Break | 70% | 40% | 60% |

| Modulus of Elasticity (GPa) | 193 | 193 | 193 |

Impact of PVD on the Mechanical Integrity of Stainless Steel

Coating Without Compromise

Physikalische Gasphasenabscheidung (PVD) is a surface treatment process, not a structural modification technique. It deposits a thin metallic film (e.g., titanium nitride, zirconium) onto the stainless surface in a vacuum chamber at temperatures between 150°C and 450°C. Unlike heat-intensive coatings such as powder-coat or electroplating, PVD does not distort grain boundaries or compromise internal strength.

In controlled ASTM D3359 peel tests, PVD-coated stainless steel retained 98% of its original adhesion and tensile flexibility, proving that it performs like raw material under mechanical stress. Researchers at the Journal of Materials Processing Technology reported no measurable change in base yield strength after multiple PVD coating cycles on 304 stainless samples.This means your structural reliability is fully preserved, even after applying decorative or protective finishes. Whether used in elevators, wall panels, or furniture, PVD stainless stays tough inside and out.

Thermal Expansion and Residual Stress

One concern in metal coatings is the introduction of residual thermal stress. However, the coefficient of thermal expansion (CTE) for most PVD layers closely matches that of stainless steel (approx. 16.5 µm/m·K), minimizing delamination risk. Finite Element Analysis (FEA) simulations show less than 2.5% stress concentration near edges post-coating, compared to over 10% with traditional paints or lacquers.

PVD enhances surface durability without degrading flexibility, making it ideal for parts that will be bent, punched, or tension-mounted after finishing.

Load-Bearing and Bending Resistance Performance

Performance Under Real-World Stress

When it comes to load-bearing applications, not all decorative materials are created equal. But PVD-coated stainless steel sheet is an exception—it not only looks premium but also performs under weight and dynamic stress.

A 1.5mm thick stainless steel sheet, mounted with a 50 cm span, can sustain point loads up to 130 kg without permanent deformation. In cantilever setups, deflection remains under 2 mm at 100 kg, which is well within structural code limits for interior panels or cladding.These values prove PVD stainless isn’t just a visual upgrade—it’s structurally sound and built for heavy-duty use.

Flexural Strength in Panel-Based Applications

Flexural strength refers to a material’s ability to resist bending forces without cracking or yielding. In lab tests:

-

304 PVD stainless steel sheets maintained flexural strength up to 1.7 GPa

-

316 sheets reached slightly higher at 1.9 GPa

-

Both retained 95% strength after 1,000 bending cycles at 30° angles

These figures reflect exceptional fatigue resistance, especially in applications like door trims, column wraps, signage boards, and custom stainless steel products that require both rigidity and finish.

Supporting Structures and Mounting Efficiency

To achieve maximum load-bearing value:

-

Use stainless sheets no thinner than 1.2mm for horizontal or overhead applications.

-

Apply double-rivet mounting at 100–120 mm intervals to avoid sag.

-

Ensure proper backing frames (aluminum or galvanized) to distribute force evenly.

-

Avoid excessive edge grinding, which can reduce tensile stability by up to 20%.

Following these steps ensures your PVD stainless installation will hold up over time—both aesthetically and structurally.

Corrosion Resistance Under Extreme Conditions

Performance in Salt Spray, Humidity, and Acidic Environments

PVD stainless steel consistently outperforms other finishes when exposed to highly corrosive environments. In ASTM B117 Salzsprühtests, PVD-coated 304 stainless steel withstood over 1,000 continuous hours of salt fog without exhibiting pitting, edge rust, or color fade. In contrast, untreated 304 stainless began developing rust near drilled holes and cut edges within 240–300 hours, while painted metal panels showed bubbling and delamination before 200 hours.

Humidity plays a critical role in long-term finish degradation. At 95% relative humidity and 38°C, PVD-coated stainless steel showed no surface dulling or color change even after three continuous weeks. On the other hand, uncoated stainless developed a brownish patina around fasteners and welded edges by day 6, while painted surfaces began chalking and fading visibly within 10 days.

Acidic exposure tells a similar story. When exposed to pH 3.5 synthetic acid rain solution, painted metal surfaces began to show microscopic cracking and surface blistering within 48 hours, while uncoated stainless steel displayed visible tea staining in etched patterns. PVD-coated panels remained unaffected even after 96 hours of direct spray exposure under controlled lab conditions.

| Material Type | Salt Spray (ASTM B117) | High Humidity (95%, 38°C) | Acid Exposure (pH 3.5) |

|---|---|---|---|

| Uncoated 304 Stainless Steel | 240–300 hours (pitting) | Dulling & rust in 6–8 days | Tea staining by 48 hrs |

| Painted Carbon Steel | Peeling in 180 hours | Chalks after 7–10 days | Blistering in 48 hrs |

| PVD-Coated Stainless Steel | >1,000 hrs no rust | No change at 21+ days | Stable at 96+ hrs |

These performance differences directly impact product lifespan, maintenance costs, and visual consistency. A commercial kitchen backsplash or outdoor cladding system built with stainless steel sheet using PVD coating will retain its integrity and appearance for over a decade with no repainting or surface treatment.

Comparison with Uncoated and Painted Metal Sheets

Painted finishes typically rely on acrylic or polyester coatings applied in liquid or powder form, which adhere to the surface mechanically. These layers degrade quickly when scratched, thermally cycled, or chemically attacked. Once a painted surface is compromised, the underlying carbon steel begins to oxidize—often unseen until the damage spreads.

Uncoated stainless steel, such as 304 or 316 grades, performs better but still remains vulnerable to tea staining, especially in chloride-rich coastal air. The problem amplifies when surfaces are textured, brushed, or have edges that trap moisture.

PVD coating, by contrast, forms a diffusion-bonded nanolayer of nitrides, carbides, or oxides—typically only 1–5 microns thick, but incredibly stable. This finish doesn’t peel, blister, or delaminate because it becomes part of the metal surface through physical vapor deposition at 300–500°C in vacuum chambers. Its hardness reaches 2,000+ HV, far exceeding paint’s scratch resistance (typically under 200 HV).

| Property | Lackierter Stahl | Uncoated Stainless Steel | PVD Stainless Steel |

|---|---|---|---|

| Scratch Resistance | <200 HV | ~150–180 HV | 2,000+ HV |

| Color Stability (UV Exposure) | 2–3 years fade | Slight darkening over time | 10+ years stable |

| Chloride Resistance | Poor | Moderate (needs passivation) | Excellent |

| Maintenance Requirement | Repainting every 3–5 years | Surface cleaning monthly | Minimal |

When used in architectural cladding, transit interiors, or Edelstahlprodukt applications, PVD-coated sheets dramatically reduce the frequency of surface degradation-related interventions. Clients avoid repainting costs, early panel replacements, and aesthetic inconsistencies.

Designers and engineers choose PVD not just for looks, but for measurable performance in real-world settings. Whether it’s urban pollution, oceanfront mist, or food-grade chemical exposure, it’s a surface finish that holds its ground—year after year.

Durability in High-Traffic Applications

Resistance to Impact, Denting, and Repeated Physical Contact

PVD-coated stainless steel sheets excel in environments where physical abuse is inevitable. The PVD layer creates a surface that not only resists scratches but also withstands impacts and dents far better than traditional finishes. Tests reveal that PVD coatings increase surface hardness to above 2,000 Vickers Hardness (HV), compared to around 150-200 HV for typical uncoated stainless steel. This hardness directly correlates with improved dent resistance, making the material ideal for places like elevator doors, escalator panels, and public fixtures, where repeated knocks and scrapes occur daily.

The PVD layer acts like a thin armor, preventing micro-scratches from expanding into visible damage. This means surfaces maintain their visual appeal and structural integrity, even under heavy human traffic and constant contact with objects like shopping carts, luggage, or cleaning tools.

Industries report that PVD-coated stainless steel products last 3 to 5 times longer in harsh public-use environments than painted or polished stainless steel alternatives. The durability reduces maintenance frequency and lowers lifecycle replacement costs, saving both time and money.

Lifespan in Public and Commercial Environments

In settings such as airports, shopping malls, hospitals, and subways, the constant flow of people subjects materials to millions of touches and impacts annually. Stainless steel sheet with PVD coating retains its finish without dulling or peeling over at least a 15-year lifespan, even with minimal cleaning routines.

Laboratory simulations subject PVD-treated panels to 1 million abrasion cycles using a Taber Abraser machine, which mimics wear from shoes, luggage wheels, and cleaning equipment. The results show less than 5% loss of gloss after the full test—proof of the coating’s remarkable resilience.

| Material Type | Surface Hardness (HV) | Abrasion Resistance (Cycles) | Typical Lifespan (Years) | Maintenance Frequency |

|---|---|---|---|---|

| Painted Stainless Steel | 150–200 | <100,000 | 3–5 | Repainting every 2–3 yrs |

| Uncoated Stainless Steel | 180–220 | ~300,000 | 7–10 | Polishing 2–4 times/yr |

| PVD-Coated Stainless Steel | >2,000 | >1,000,000 | 15+ | Minimal cleaning only |

Maintenance protocols for PVD finishes require only mild detergents and soft cloths, avoiding harsh chemicals or abrasive pads. This simplicity reduces cleaning labor costs and lowers the risk of accidental damage during maintenance.

Commercial operators appreciate how PVD-coated stainless steel maintains a consistent appearance under high-traffic stress, which upholds brand image and customer satisfaction. For example, elevator doors clad in PVD-treated panels continue to look polished and scratch-free after years of heavy use, outperforming traditional brushed or painted options.

In summary, PVD coatings transform stainless steel into a robust, long-lasting material suited for the toughest public environments. This strength, combined with its ease of care, drives widespread adoption in demanding architectural and product applications such as stainless steel products.

Learn more: What is a PVD stainless steel sheet?