304 stainless steel remains cost-effective for interiors, decorative panels, and low-exposure areas. Stainless steel exterior wall panels in 316 maintain uniform color, resist rust, and survive extreme weather conditions. Choosing the correct grade allows architects to balance upfront cost, longevity, and aesthetic performance, ensuring buildings stay visually appealing for years without frequent repairs.

1. Material Composition and Corrosion Resistance

1.1 Chemical Differences Between 304 and 316 Stainless Steel

When architects choose between 304 and 316 stainless steel, understanding their chemical composition is the first step. 304 neoksidebla ŝtalo contains roughly 18% chromium and 8% nickel, giving it solid corrosion resistance for most indoor applications. In contrast, 316 neoksidebla ŝtalo adds 2-3% molybdenum, which significantly improves its ability to withstand harsh environments, especially areas exposed to saltwater or chemical pollutants.

This difference means that for exterior cladding or coastal façades, 316 often outperforms 304 in long-term durability. For example, in high-rise buildings near the ocean, 316 stainless steel sheets resist pitting and rust far better than 304, making them a preferred choice for exterior panels or structural elements.

| Property | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Kromo (Cr) | 18% | 16–18% |

| Nikelo (Ni) | 8–10% | 10–14% |

| Molibdeno (Mo) | 0% | 2–3% |

| Corrosion Resistance | Good (indoors, mild conditions) | Excellent (coastal, harsh environments) |

| Tensile Strength | ~505 MPa | ~515 MPa |

| Formability | Easy to form | Slightly harder due to higher strength |

| Best Applications | Interior panels, railings, decorative elements | Exterior façades, balcony railings, coastal structures |

1.2 Corrosion Resistance in Humid and Coastal Environments

When you’re designing structures in humid or coastal regions, corrosion resistance becomes critical. 304 neoksidebla ŝtalo can handle indoor humidity and occasional rain exposure, but over time, it may start to show signs of staining or surface wear. On the other hand, 316 neoksidebla ŝtalo maintains its appearance and integrity even under constant exposure to salt-laden air.

For practical applications, think about using Stain Steel Sheets for decorative features or panels where both aesthetics and long-term resistance matter. 316’s molybdenum content creates a protective barrier that reduces corrosion and keeps surfaces looking polished for years.

1.3 Resistance to Staining and Oxidation

Another factor is how these metals handle staining and oxidation. 304 neoksidebla ŝtalo resists most staining but can discolor in harsh outdoor conditions, especially if maintenance is inconsistent. 316 neoksidebla ŝtalo, however, shows far better resistance to rust spots and oxidation, making it ideal for high-profile architectural surfaces like exterior wall panels or metal cladding facades.

For instance, modern office buildings often use stainless steel exterior wall panels for a sleek, reflective finish that withstands rain, humidity, and industrial pollutants. Choosing 316 in these scenarios reduces maintenance frequency and keeps the building looking sharp over time.

2. Mechanical Properties and Strength

2.1 Tensile Strength and Hardness Comparison

When it comes to architectural applications, understanding tensile strength and hardness is crucial. 304 neoksidebla ŝtalo offers good strength for most indoor or lightly exposed structures, making it ideal for railings, staircases, and interior panels. 316 neoksidebla ŝtalo, however, provides higher tensile strength, which makes it perfect for coastal balconies, exterior cladding, or large façade panels that need to withstand wind loads and structural stress.

For example, in a seaside hotel renovation, designers chose Neoksidebla Ŝtalo Metala Plato for balcony railings and support beams. This choice ensured that even during heavy storms, the material maintained its integrity without warping or cracking. Strength and durability like this allow architects to design more ambitious, open-concept exteriors without compromising safety or aesthetics.

2.2 Flexibility and Formability for Architectural Applications

Another critical factor is how easily the metal can be shaped into complex designs. 304 neoksidebla ŝtalo bends and forms relatively easily, so it works well for intricate interior panels or decorative railings. 316 neoksidebla ŝtalo can also be formed but requires slightly more effort due to its higher strength.

Here’s a practical workflow architects and fabricators follow:

-

Measure and plan the panel layout carefully, considering bends, joints, and anchor points.

-

Cut the metal plates to size, ensuring edges are smooth to prevent future corrosion.

-

Bend or roll the sheets using hydraulic presses or brake machines. For exterior façades, slight overbending helps compensate for thermal expansion.

-

Inspect each piece for scratches, dents, or uneven surfaces before installation.

In a recent commercial office project, Metala Neoksidebla Ŝtalo Folio panels were custom-rolled to create a curved façade. The result was a modern, flowing exterior that reflected sunlight beautifully, while 316 stainless steel’s durability ensured the curves remained flawless over time.

2.3 Impact of Temperature on Structural Integrity

Temperature fluctuations also affect stainless steel performance. 304 neoksidebla ŝtalo handles indoor temperatures and mild seasonal changes well, but extreme heat or cold can reduce its hardness slightly. 316 neoksidebla ŝtalo resists thermal expansion and contraction better, which is critical for exterior walls or rooftop structures exposed to sun, wind, and occasional frost.

For instance, a rooftop pergola in a coastal city used 316 stainless steel sheets for the structural frame. Even after summer heat and winter chills, the pergola maintained straight lines and smooth joints without any visible warping. Choosing the right stainless steel type here directly reduces long-term maintenance and replacement costs.

3. Cost and Long-Term Value

3.1 Initial Material and Fabrication Costs

When planning an architectural project, cost is always a factor. 304 neoksidebla ŝtalo is generally more affordable upfront than 316, making it a common choice for interior railings, staircases, or decorative panels where extreme corrosion resistance isn’t critical. 316 neoksidebla ŝtalo costs more, but its longdaŭra daŭripovo often justifies the higher price, especially for exterior applications.

| Karakterizaĵo | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Initial Material Cost | Lower | Higher |

| Fabrication Difficulty | Easier to form and weld | Slightly harder to form due to higher strength |

| Maintenance Frequency | Moderate, more cleaning needed outdoors | Low, highly corrosion-resistant |

| Expected Lifespan (Outdoor) | 5–10 years in harsh environments | 15–20+ years |

| ROI Consideration | Lower upfront, higher maintenance | Higher upfront, long-term savings |

For example, a luxury beachfront restaurant invested in Metala Neoksidebla Ŝtalo Folio for the exterior cladding. While the initial cost was higher than using 304, the owner avoided future repainting, replacement, and rust repair expenses, which would have added up over the next 10–15 years. Spending a little more upfront can save significant maintenance costs later.

3.2 Maintenance and Replacement Expenses

Maintenance is where the difference between 304 and 316 becomes clear. 304 neoksidebla ŝtalo may require regular cleaning, polishing, and occasional touch-ups if exposed to coastal or industrial environments. 316 neoksidebla ŝtalo requires far less attention due to its molybdenum-enhanced corrosion resistance.

Here’s a simple maintenance workflow for exterior panels:

-

Inspect surfaces quarterly for stains, dirt, or oxidation spots.

-

Rinse with fresh water to remove salt or pollutants.

-

Polish lightly using a soft cloth and non-abrasive cleaner if minor stains appear.

-

Check joints and fasteners annually, tightening or replacing as needed.

A recent commercial building used Neoksidebla Ŝtalo Ekstera Muro panels. Even after two years in a coastal environment, the walls remained spotless, and maintenance required only occasional rinsing. This reliability is a huge advantage for property owners and facilities managers.

3.3 ROI Considerations for Architectural Projects

When evaluating return on investment (ROI), it’s essential to look beyond initial costs. 316 neoksidebla ŝtalo often provides better ROI for high-exposure applications because it maintains aesthetics, reduces maintenance frequency, and extends lifespan.

Consider this scenario:

-

A high-rise apartment complex installed 316 panels on the balconies and façade.

-

Over 10 years, the building avoided repainting or panel replacement, which would have cost thousands if 304 had been used.

-

Tenants appreciated the clean, modern look maintained over time, which enhanced property value and occupancy rates.

Investing in the right stainless steel type upfront not only protects the building structure but also enhances long-term economic value.

4. Aesthetic Appearance and Finish Options

4.1 Surface Finishes and Visual Appeal

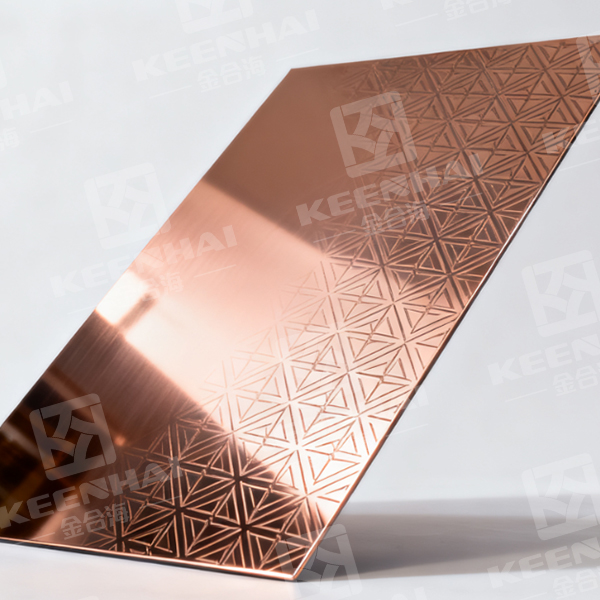

In architecture, how stainless steel looks is just as important as how it performs. 304 neoksidebla ŝtalo often features polished, brushed, or matte finishes that work beautifully for interior walls, railings, and decorative elements. 316 neoksidebla ŝtalo offers the same finish options but maintains its shine and color longer when exposed to harsh outdoor conditions.

| Finish Type | 304 Stainless Steel | 316 Stainless Steel | Notes |

|---|---|---|---|

| Polished | Shiny, may show water spots | Shiny, maintains luster outdoors | Best for interior or controlled environments |

| Brosita | Hides minor scratches | Hides scratches, resists stains | Ideal for exterior façades and high-contact surfaces |

| Matte / Satin | Soft, elegant look | Durable, resists oxidation | Good for decorative panels or exterior walls |

For instance, a boutique hotel in a coastal city installed Neoksidebla Ŝtalo Metala Plato panels on its lobby façade. The brushed finish reflected natural light softly, creating an inviting atmosphere while resisting fingerprints and minor scratches. Designers appreciated how the material stayed consistent even after years of heavy use.

4.2 Longevity of Polished and Brushed Surfaces

The choice between polished and brushed surfaces can impact long-term maintenance. Polished surfaces look striking but show water spots more easily, while brushed finishes hide minor scratches and stains better. Using 316 neoksidebla ŝtalo for exterior cladding ensures that these finishes remain uniform, even in coastal or high-pollution environments.

For example, a commercial office building used Metala Neoksidebla Ŝtalo Folio with a brushed finish for its exterior panels. Over three years, the façade remained visually consistent, needing only periodic rinsing to remove accumulated dust. This makes 316 stainless steel a smart choice for buildings aiming to maintain a premium look with minimal upkeep.

4.3 Color Consistency and Weathering Effects

Color consistency and weathering are key considerations for architects working on modern façades. 304 neoksidebla ŝtalo may gradually develop slight discoloration if exposed to harsh coastal conditions, while 316 neoksidebla ŝtalo retains its metallic luster over time.

A recent high-rise apartment used 316 stainless steel exterior panels to create a reflective façade. Even after two summers with strong sunlight and occasional storms, the color and shine stayed consistent. Choosing the right stainless steel type ensures that your building maintains a fresh, professional appearance for years.

5. Application Scenarios in Architecture

5.1 Exterior vs Interior Usage Suitability

When choosing between 304 and 316 stainless steel, the location of installation matters. 304 neoksidebla ŝtalo performs exceptionally well indoors—for railings, staircases, kitchen panels, or decorative interior walls. It resists everyday humidity and occasional cleaning chemicals, making it perfect for spaces with controlled conditions.

| Application | Recommended Stainless Steel | Notes |

|---|---|---|

| Interior Panels & Railings | 304 | Cost-effective, easy to form, suitable for low-exposure areas |

| Exterior Façades & Cladding | 316 | Superior corrosion resistance, retains appearance in coastal/high-pollution environments |

| Balconies & Structural Supports | 316 | Handles wind loads, high tensile strength, long-term durability |

| Decorative Elements | 304 or 316 | Depending on exposure and aesthetic requirements, 316 preferred outdoors |

316 neoksidebla ŝtalo shines outdoors, especially for façades, balcony railings, and exterior cladding where exposure to rain, wind, and pollutants is constant. In a seaside condominium project, architects installed Neoksidebla Ŝtalo Ekstera Muro panels along the building façade. Even after two years of salty air and heavy storms, the panels retained their smooth finish and metallic sheen, proving 316’s superior outdoor durability.

5.2 High-Exposure Environments like Coastal Areas

Coastal areas, industrial zones, or high-rise buildings face constant exposure to moisture, salt, and airborne pollutants. Using 316 neoksidebla ŝtalo in these environments minimizes staining, pitting, and long-term degradation.

For example, a waterfront hotel chose 316 stainless steel cladding for its balcony railings and rooftop pergolas. The design not only looked sleek and modern but also remained low-maintenance, allowing the property team to focus on guest experience instead of constant upkeep.

5.3 Structural vs Decorative Elements

Different parts of a building have different requirements:

-

Structural elements like beams, support frames, and high-load railings benefit from 316 neoksidebla ŝtalo due to its higher tensile strength and corrosion resistance.

-

Decorative panels and interior features often use 304 neoksidebla ŝtalo, which is easier to form and polish while remaining cost-effective.

By matching the stainless steel type to the application, architects optimize both cost and longevity. In projects where clients value premium quality and brand reliability, specifying stainless steel from reputable suppliers ensures confidence in material performance.

If you’re exploring stainless steel options for architectural use, the team at pvdstainlesssteel provides a range of high-quality sheets and panels suitable for both interior and exterior applications.