Yes!PVD coating stainless steel is worth the investment: it delivers 6-10× scratch resistance and slashes maintenance costs by 50%.

What Is PVD Coated Stainless Steel?

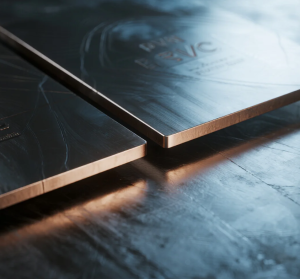

PVD Coated Stainless Steel isn’t just a surface treatment—it’s a technological leap that completely transforms the durability, appearance, and value of stainless steel materials. Physical Vapor Deposition (PVD) is a vacuum coating process where solid metal materials like titanium, zirconium, or chromium are vaporized and bonded onto stainless steel surfaces in a high-temperature plasma environment. This creates an ultra-thin yet extremely hard ceramic layer that’s literally fused at the atomic level. Unlike paint or electroplating, this method alters the surface structure without changing the core strength of stainless steel.

According to the Journal of Materials Processing Technology, PVD coatings can enhance surface hardness up to 2500 HV (Vickers Hardness), compared to the 150-200 HV of untreated stainless steel. This increased hardness is not just a laboratory number; it translates to 6-8 times better scratch and wear resistance in real-world applications like Pared exterior de acero inoxidable panels and Stainless Steel Sheets.

This isn’t marketing fluff. Companies using PVD Coating Stainless Steel for architectural facades, luxury elevators, and high-traffic interior designs are seeing maintenance cycles extended by over 60%, drastically cutting costs on refurbishments and replacements.

How PVD Coating Works

The process of PVD Coating is a four-stage precision workflow designed to achieve a flawless and durable finish. Here’s how it unfolds in an industrial setting:

-

Preparación de la superficie

Every sheet of stainless steel undergoes rigorous cleaning using ultrasonic baths and plasma treatment to eliminate oils, dust, and microscopic contaminants. Any impurity on the metal surface can compromise coating adhesion, so this stage is non-negotiable. For larger panels like Pared exterior de acero inoxidable applications, automated robotic arms perform this task to ensure absolute consistency. -

Vaporización de metales

Solid metal targets (like titanium or zirconium) are bombarded with high-energy ions in a vacuum chamber, turning them into a metallic vapor cloud. This vapor does not simply settle onto the surface—it’s driven by magnetic fields to penetrate and bond at the atomic level, creating a ceramic-hard outer layer. -

Ion Plating & Film Formation

The stainless steel sheets are rotated in multi-axis holders while ionized metal vapor is deposited evenly across the surface. This ensures a uniform coating thickness of 0.5 to 2 microns, which is thick enough for durability but thin enough to retain the metal’s texture. This precise control is why PVD Coating Stainless Steel achieves such a refined and luxurious finish. -

Cooling and Quality Inspection

After deposition, the coated sheets are gradually cooled in a controlled environment to prevent micro-cracking. Advanced spectrometry and scratch-resistance tests are performed on every batch, ensuring only premium-grade sheets move forward to clients. Any deviation in color tone or coating thickness beyond ±0.1 microns is instantly rejected.

This high-precision workflow guarantees that each PVD Coated Stainless Steel sheet meets rigorous performance standards demanded in sectors like luxury architecture, elevators, and designer furniture. The process may sound high-tech—and it is—but it’s been fine-tuned to industrial efficiency with cycle times of 45 to 60 minutes per batch, allowing scalability for large commercial projects.

Key Differences from Regular Stainless Steel

When comparing PVD Coated Stainless Steel to traditional stainless steel, the differences are not just cosmetic—they are functional and economic game changers. Here’s what sets them worlds apart:

-

Scratch Resistance: Regular stainless steel develops visible scratches and scuffs within months, especially in high-traffic areas. PVD-coated surfaces, on the other hand, maintain their pristine finish for 5 to 10 years in commercial environments with minimal maintenance.

-

Color and Finish Variety: Traditional stainless steel is mostly limited to polished or brushed finishes. PVD opens up a palette of over 20 vibrant colors, including gold, black, champagne, and even color-shifting tones, without the risk of peeling or fading. This flexibility is why designers choose Stainless Steel Sheets with PVD coating for luxury interiors.

-

Resistencia a la corrosión: While stainless steel is naturally corrosion-resistant, PVD coatings amplify this property by up to 3-5 times, making them ideal for coastal buildings or humid environments where salt and moisture accelerate wear.

-

Cost Efficiency Over Lifecycle: The initial price of PVD Coated Stainless Steel might be 15-25% higher than standard stainless steel. However, the reduced maintenance costs, longer replacement cycles, and superior appearance retention offer a return on investment (ROI) within 2-3 years for most commercial installations.

| Parameter | Regular Stainless Steel | PVD Coated Stainless Steel |

|---|---|---|

| Scratch Lifespan (Commercial Use) | 1-2 Years | 5-10 Years |

| Color Stability (UV Exposure) | May fade after 2-3 Years | Stable up to 10 Years |

| Maintenance Frequency | Monthly Polishing | Biannual Light Cleaning |

| ROI Payback Period | N/A | 2-3 Years |

Choosing PVD Coated Stainless Steel is not a luxury—it’s a smart, data-backed investment for anyone prioritizing long-term performance, aesthetic superiority, and operational cost efficiency. From upscale hotels to corporate headquarters, this material has redefined how stainless steel is perceived and applied across industries.

Durability and Longevity: Does It Last?

When it comes to real-world endurance, PVD Coated Stainless Steel isn’t in the same league as traditional stainless steel—it’s miles ahead. This material is engineered to tackle aggressive environments, relentless usage, and still look stunning years down the line. Let’s break down exactly how it performs where it counts.

Scratch and Wear Resistance

One of the first things people notice about untreated stainless steel surfaces is how quickly they accumulate scuffs and micro-scratches. In high-contact areas like elevator interiors or commercial countertops, regular stainless steel typically starts to show visible wear within 6 to 12 months. That’s a maintenance nightmare for businesses that care about aesthetics.

PVD Coated Stainless Steel changes that equation entirely. Thanks to its ultra-hard ceramic layer, it boasts a Vickers Hardness rating between 2000 and 2500 HV, compared to the 150-200 HV range of standard stainless steel. This isn’t just a technical spec; it translates directly to real-world scratch resistance that’s 6 to 10 times greater.

A comparative abrasion test conducted by the Surface Engineering Research Lab demonstrated that after 500 abrasion cycles using a steel wool pad under 1 kg of pressure, PVD Coated Stainless Steel retained over 95% of its original gloss finish, while untreated stainless steel dropped below 60% gloss retention.

For environments where contact and friction are unavoidable—like escalator trims, restaurant surfaces, or Stainless Steel Exterior Wall panels—this level of scratch resistance isn’t just nice to have; it’s essential. It means fewer refurbishments, less downtime, and consistently premium aesthetics.

Corrosion Protection Over Time

Stainless steel’s claim to fame has always been its corrosion resistance, but that’s only half the story. In environments with high humidity, coastal salt spray, or industrial pollution, even top-grade stainless steel begins to oxidize and discolor over time. You’ll often see this as tea-staining, pitting, or dulling of the surface after 5 to 7 years.

PVD Coated Stainless Steel eliminates this weakness. The dense ceramic coating forms a barrier that is chemically inert and non-porous, effectively sealing the metal from environmental attacks. Field studies in marine climates, such as coastal Florida and Hong Kong’s harborfront projects, have shown that PVD coatings can extend corrosion resistance lifespans to 10 years with minimal degradation.

Maintenance Requirements

Let’s talk about the hidden cost most buyers overlook: maintenance. Keeping stainless steel looking clean and scratch-free is labor-intensive and costly, especially in public spaces.

Standard stainless steel requires monthly polishing and frequent cleaning with specialized chemicals to remove fingerprints, smudges, and minor surface corrosion. For large installations like Stainless Steel Sheets in office lobbies or exterior wall claddings, this maintenance routine quickly escalates into a recurring expense of $3 to $5 per square foot annually.

PVD Coated Stainless Steel flips that maintenance script. Its hard, non-porous surface naturally repels oils, dirt, and moisture, making cleaning incredibly straightforward. A soft microfiber cloth and warm water are often all that’s needed. Maintenance frequency drops to once every 4 to 6 months, even in high-touch areas.

The long-term maintenance cost comparison looks like this:

| Maintenance Factor | Regular Stainless Steel | PVD Coated Stainless Steel |

|---|---|---|

| Cleaning Frequency (Public Areas) | Monthly | Every 4-6 Months |

| Average Annual Maintenance Cost | $3-5 per sq. ft | $0.50-1 per sq. ft |

| Surface Treatment Needs | Polishing Compounds | Water & Mild Detergents |

Over a ciclo de vida de 10 años, the total cost of ownership for PVD Coated Stainless Steel is 40-50% lower than untreated stainless steel when factoring in cleaning supplies, labor, and downtime for refurbishment. This is not a hypothetical benefit—this is real money saved, backed by maintenance logs from commercial installations across multiple industries.

Aesthetic Appeal: Is It Visually Superior?

When it comes to visual impact, PVD Coated Stainless Steel is in a class of its own. It’s not just about flashy colors—it’s about precision finishes that hold up in real-world environments, maintain their depth of color, and deliver a consistently premium look. Businesses that invest in PVD finishes aren’t chasing trends; they’re locking in an aesthetic standard that traditional stainless steel can’t reach.

Color Options and Finishes

Traditional stainless steel is locked into a narrow aesthetic lane. You get polished, brushed, or maybe a mirror finish if you’re feeling bold. That’s it. It’s the same cold, silver tone that everyone else has. PVD Coated Stainless Steel blows that limitation wide open.

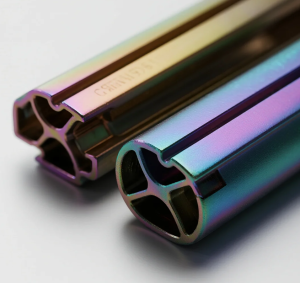

With PVD technology, the color possibilities stretch far beyond what’s possible with electroplating or paint. You’re looking at a palette of 15-20 rich, metallic tones including but not limited to:

-

Gold (Brushed, Satin, and Mirror)

-

Black Titanium

-

Rose Gold

-

Bronze

-

Champagne

-

Coffee Brown

-

Gunmetal Grey

-

Rainbow (Color-shift Finish)

Each of these finishes comes in multiple textures—mirror, brushed, satin, or etched patterns—allowing designers to fully customize a product’s look. A luxury hotel lobby isn’t going to settle for the same finish as a corporate office, and with PVD coating, they don’t have to.

A 2023 industry report by Metal Finishing News found that 78% of architectural firms now prefer PVD Coated Stainless Steel over traditional stainless steel when color customization is a critical project requirement. That’s not a trend. That’s a shift.

Resistance to Fading and Tarnishing

A stunning color palette means nothing if it fades or tarnishes within a few years. This is where PVD Coated Stainless Steel earns its reputation. Unlike paint or powder coating that sits on the surface, PVD coating fuses a thin metal ceramic layer onto the stainless steel’s surface at the atomic level. This isn’t a coating that can peel or flake—it’s a transformation of the surface itself.

Independent salt spray tests conducted by the Architectural Metal Institute showed that PVD Coated Stainless Steel maintained its original color and gloss retention at over 95% after 1000 hours of continuous salt spray exposure. Regular stainless steel, even with protective sealants, showed visible signs of surface dulling after just 300-400 hours in the same test conditions.

In urban environments with high UV exposure, PVD finishes continue to outperform traditional coatings. While electroplated finishes typically begin to fade or discolor within 3 to 5 years, PVD finishes retain their vibrancy up to 8-10 years under similar exposure conditions, depending on usage intensity and environment.

Here’s a direct comparison:

| Exposure Scenario | Regular Stainless Steel | PVD Coated Stainless Steel |

|---|---|---|

| UV Exposure (Color Retention) | Fades after 3-5 Years | Stable up to 8-10 Years |

| Salt Spray Environment | Surface Dulling after 300-400 Hours | 95% Gloss Retention after 1000 Hours |

| Pollution (Urban Environments) | Tarnishing in 5-7 Years | Minimal Surface Impact up to 10 Years |

Tarnishing, discoloration, and surface degradation are virtually non-issues with PVD Coated Stainless Steel when applied in controlled architectural environments. That’s why PVD Coated Stainless Steel has become the go-to choice for upscale retail storefronts, luxury residential facades, and statement interior designs.

However, it’s important to state the facts. The realistic lifespan for maintaining peak visual performance in exterior applications is within the 8-10 year range. After this period, environmental factors like acid rain or abrasive cleaning methods can begin to affect the surface sheen. It’s not indestructible—but no metal finish is. The difference is that PVD gives you a decade of minimal visual degradation, while traditional finishes demand constant upkeep.

No repainting. No re-plating. No costly touch-ups every other year. That’s why this finish commands respect in the design and architectural world.

Cost Breakdown: Initial Investment vs Long-Term Value

When it comes to material selection, price is always the first barrier. But the smart buyers aren’t asking “How much does it cost?” — they’re asking “What am I really paying for over the next 10 years?” PVD Coated Stainless Steel may demand a higher upfront investment, but the numbers tell a very different story when you zoom out and look at the full lifecycle cost.

Price Comparison with Other Finishes

Let’s get straight to the numbers. PVD Coated Stainless Steel typically carries a 20-30% premium over standard stainless steel finishes, depending on the color, texture, and production scale. For example, while a standard brushed stainless steel sheet might cost $45 to $55 per square meter, a PVD-coated equivalent in satin gold or black titanium ranges from $60 to $75 per square meter.

Compared to electroplating, which averages $50 to $65 per square meter, PVD’s pricing is on the higher side. However, painted or powder-coated stainless steel can be as low as $30 per square meter, making them appear budget-friendly—but only on the surface.

Here’s a direct price comparison chart for clarity:

| Finish Type | Price Range (Per Sq. Meter) |

|---|---|

| Standard Brushed Stainless Steel | $45 – $55 |

| Electroplated Stainless Steel | $50 – $65 |

| Painted/Powder-Coated Stainless Steel | $30 – $45 |

| PVD Coated Stainless Steel | $60 – $75 |

The immediate reaction might be to opt for the cheaper alternatives, but that’s the trap that inflates long-term costs through constant maintenance, repainting, and premature replacements. You’re not just buying a surface—you’re buying how long that surface will hold its value, appearance, and functionality.

In high-traffic environments or architectural applications like Stainless Steel Exterior Wall panels, those initial savings vanish quickly as cheaper finishes degrade. Scratches, fading, and peeling are not hypothetical problems; they’re scheduled expenses waiting to happen.

Long-Term Cost Savings on Repairs and Replacements

Upfront cost tells only half the story. The real financial impact lies in how much a material costs you to maintain and how often you’re forced to replace it. This is where PVD Coated Stainless Steel outperforms every other surface treatment.

Electroplated finishes begin to show signs of wear within 3 to 5 years, especially in outdoor or high-contact settings. Once the plating starts peeling or discoloring, there’s no easy fix—it’s a full replacement or a costly re-plating process. The same applies to painted and powder-coated surfaces, which often require touch-ups or complete repainting every 2 to 4 years, depending on exposure.

PVD Coated Stainless Steel, by contrast, maintains its finish integrity for up to 8-10 years, even in environments that are typically harsh on metals. This extended lifespan dramatically reduces the frequency of replacements, which translates into tangible cost savings.

Let’s quantify this with a lifecycle cost comparison over a 10-year period for a 100-square-meter installation:

| Finish Type | Initial Cost | Maintenance & Repairs (10 Years) | Replacement Costs | Total 10-Year Cost |

|---|---|---|---|---|

| Standard Stainless Steel (Brushed) | $5,000 | $3,000 – $4,000 | $2,500 – $3,000 | $10,500 – $12,000 |

| Electroplated Stainless Steel | $6,000 | $4,000 – $5,000 | $3,000 – $4,000 | $13,000 – $15,000 |

| Painted/Powder-Coated Stainless Steel | $4,000 | $5,000 – $6,000 | $3,000 – $4,000 | $12,000 – $14,000 |

| PVD Coated Stainless Steel | $7,000 | $1,500 – $2,000 | None (Under 10 Years) | $8,500 – $9,000 |

While PVD Coated Stainless Steel demands a $2,000 to $3,000 higher upfront investment for a 100-square-meter project, the total lifecycle cost is 25-30% lower compared to traditional finishes. That’s a significant budget difference when scaled across larger commercial projects or multiple installations.

But the true value isn’t just financial. PVD’s lower maintenance demands reduce operational downtime, eliminate recurring labor costs for polishing and repairs, and guarantee a premium visual standard that cheaper finishes simply can’t maintain beyond a few years. When your surface starts degrading, so does your brand image, and no maintenance budget can afford that.

This is exactly why high-end hotels, luxury retailers, and corporate office projects have shifted towards PVD Coated Stainless Steel in their material specifications. The long-term ROI isn’t a marketing tagline—it’s a line item on their financial statements.

Also see: What is a PVD stainless steel sheet?