304 stainless steel usually lasts between 25 and 50 years, depending on where it’s used and how it’s maintained. In kitchens and indoor spaces, it can serve for decades without major issues. Outdoors, factors like humidity, salt, and pollution shorten its lifespan, but with basic cleaning and inspections, it still outperforms most metals. That’s why it remains the top choice for cookware, cladding, and household products.

1. Typical Lifespan of 304 Stainless Steel

1.1 Average service life in general conditions

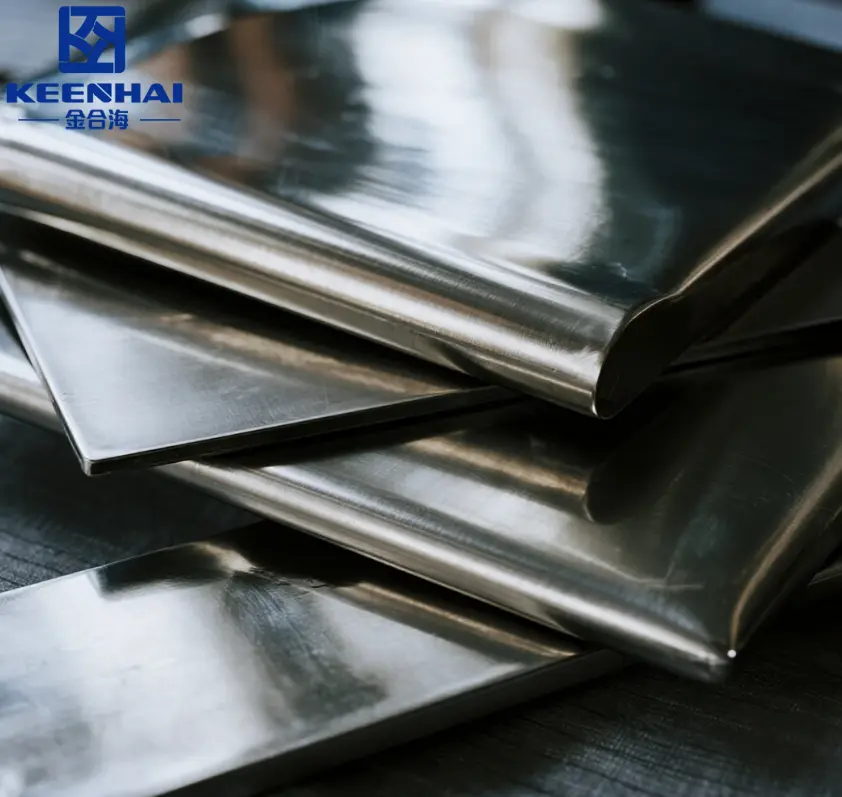

304 stainless steel has become the workhorse of modern architecture and engineering because of its remarkable balance between cost and durability. In standard environments, such as kitchens, hospitals, or indoor public spaces, a well-fabricated Stainless Steel Sheet can easily last 50–70 years without significant corrosion damage. This endurance comes from the chromium content (18–20%), which forms a protective oxide film on the surface. That film heals itself whenever scratched, preventing corrosion from advancing.

Researchers often reference ASTM exposure tests. In one study, polished 304 panels lost less than 0.01 mm thickness over 10 years in an urban environment. Such results prove why this grade dominates industries where long-term hygiene and aesthetics matter.

When evaluating its service life, three general patterns appear:

-

In low-contamination indoor areas, the steel often outlasts the building itself.

-

In semi-controlled zones like public transit stations, lifespan typically ranges from 40–50 years with periodic cleaning.

-

In moderately polluted outdoor air, panels remain structurally sound for 25–35 years, though cosmetic staining may appear earlier.

By following a straightforward cleaning routine — wiping surfaces every few months and avoiding harsh chemicals — users extend the natural life cycle without requiring replacements.

1.2 Performance in indoor vs. outdoor applications

The performance gap between indoor and outdoor installations deserves close attention. Indoors, 304 maintains its polish for decades because conditions are stable: controlled temperature, lower humidity, and absence of chloride-rich contaminants. Outdoor performance varies more dramatically depending on exposure.

A field survey in Europe tracked 304 stainless over 25 years:

-

Indoor elevator panels remained mirror-bright with minimal polishing.

-

Outdoor handrails near traffic-heavy roads developed visible tea-staining within 5–7 years.

-

Coastal samples exposed to salt spray showed pitting within 2–3 years if not cleaned.

These results highlight why outdoor projects require additional protection strategies. To preserve quality:

-

Choose finishes like brushed or electro-polished surfaces, which reduce dirt retention.

-

Schedule routine rinsing in chloride-heavy environments such as coastal towns.

-

Consider upgrading to more resistant Stainless Steel Products if salt exposure cannot be avoided.

The contrast between indoor and outdoor applications underscores the importance of context. While the alloy can last over half a century indoors, outdoor installations demand extra care to maintain appearance and prevent oxidation.

2. Environmental Factors Affecting Durability

2.1 Influence of Humidity and Oxygen

The service life of Stainless Steel Sheet largely depends on its exposure to moisture and oxygen. In dry indoor conditions, 304 stainless steel can maintain integrity for more than 60 years, while in damp and poorly ventilated rooms corrosion accelerates. The protective chromium oxide film requires oxygen to regenerate, and in environments where oxygen circulation is restricted, such as water tanks or tight crevices, the steel loses its self-healing ability. According to studies, when relative humidity exceeds 85%, the rate of surface tarnish rises by nearly 40%.

2.2 Chloride Exposure and Pitting Risks

Chloride ions remain the single greatest environmental threat to 304 stainless. In coastal cities, salty air penetrates the passive film, causing localized pits that expand over time. Engineers classify this as pitting corrosion, which progresses faster than uniform rusting. A controlled test showed that stainless exposed to 0.5% NaCl solution developed visible pits within weeks, whereas steel without chloride contact maintained surface integrity for months. For marine railings and seaside installations, many fabricators recommend upgrading to 316 stainless, which contains molybdenum for extra defense against chloride attack.

| Environment | Chloride Level (ppm) | Typical 304 Lifespan | Notes |

|---|---|---|---|

| Indoor, dry air | <10 | 60–70 years | Passive layer remains stable |

| Coastal urban areas | 100–200 | 20–30 years | Pitting risk increases |

| Marine splash zones | 300–500 | 10–20 years | Rapid corrosion without molybdenum |

| Industrial chemical sites | 500+ | <10 years | Requires duplex or 316 |

2.3 Industrial Pollution and Acidic Atmospheres

Pollution plays another major role in the lifespan of stainless steel. Sulfur dioxide, nitrogen oxides, and acid rain particles all destabilize the passive layer. In metropolitan zones with high corrosie indexes, 304 stainless often shows discoloration within five years if not regularly cleaned. Factories that release acidic fumes shorten the life expectancy even further. That is why architects frequently specify Stainless Steel Products with special finishes or coatings in polluted cities. These surface treatments, often applied by manufacturers such as pvd stainless steel, increase durability by forming an additional barrier that slows chemical attack.

2.4 High Temperature and Combined Stress Factors

Temperature amplifies every corrosive mechanism. At levels above 400°C, the chromium oxide film thickens unevenly and loses protective efficiency. Meanwhile, at sub-zero temperatures, condensation cycles create a thin water film on the metal that accelerates rusting when oxygen and contaminants are present. Engineers often point out that inox rust occurs faster under alternating heat and moisture because thermal expansion cracks the protective layer. To counteract these risks, maintenance teams adopt a simple three-step protocol:

-

Wash exposed stainless with mild detergent at least twice yearly.

-

Rinse thoroughly with clean water to remove chloride residue.

-

Dry the surface to stop water spots from creating localized corrosion cells.

These proactive measures extend the lifespan of stainless installations, especially in harsh climates where heat, humidity, and pollution converge.

3. Maintenance and Care Practices

3.1 Regular cleaning methods to prevent corrosion

Stainless steel doesn’t need complicated maintenance, but it does need consistent attention if you want it to last decades. For example, a Stainless Steel Sheet installed in a busy kitchen looks brand new for years if it gets wiped down regularly. The reason is simple: dirt and contaminants trap moisture, and moisture drives corrosie.

The easiest way to prevent this is to clean on a schedule. Here’s a practical routine most facilities follow:

-

Daily wipe-downs with warm water and a soft microfiber cloth. This removes grease, fingerprints, and dust before they settle in.

-

Weekly cleaning with a mild soap or neutral detergent. The key is to rinse thoroughly so no residue sticks around.

-

Monthly inspection for water spots, especially if the steel is exposed to hard water. If spots appear, use a mix of vinegar and water (50/50) to dissolve the minerals.

-

For areas exposed to outdoor conditions, rinsing with fresh water every two weeks helps wash away salts and pollutants before they cause trouble.

Never let residue sit for too long. Even stainless grades can show tea-staining if you leave chloride-rich grime untouched. A few minutes of routine care saves years of life on the surface.

3.2 Avoiding harsh chemicals and abrasives

One of the biggest mistakes people make is treating stainless steel like regular metal. They grab steel wool or chlorine-based cleaners, thinking it will make things “extra clean,” but in reality, they’re just damaging the protective film. The chromium oxide layer that guards the surface is thin and self-healing, but it can’t recover if you gouge it with abrasives.

There are a few clear rules everyone should follow:

-

Skip bleach, hydrochloric acid, or chlorine cleaners. These break down the oxide layer and accelerate pitting.

-

Avoid abrasive pads or powders. Even tiny scratches create rough spots where contaminants stick, which increases oxidation.

-

Use soft cloths or sponges. If you need extra strength, go for non-abrasive nylon pads instead.

-

Always clean in the direction of the polish lines. Rubbing across the grain makes scratches stand out.

Tests show that surfaces exposed to chlorine-based cleaners corrode up to 3 times faster compared to those maintained with neutral solutions. For sensitive environments like hospitals, many professionals rely on ethanol or isopropyl alcohol as disinfectants — they sanitize without harming the surface.

If you’re choosing materials for heavy-use zones, high-performance Stainless Steel Products from reliable suppliers hold up much better, but even the best grade needs proper care.

3.3 Recommended inspection and upkeep cycles

Maintenance isn’t just about wiping down surfaces; inspections matter just as much. Even the most resilient steel can show early warning signs if exposed to the wrong environment. The key is catching issues before they spread.

Here’s a practical upkeep cycle used by many commercial property managers:

-

Quarterly inspections — Walk through and look for tea-staining, tiny rust spots, or discoloration, especially on exterior railings and panels.

-

Biannual deep cleaning — Every six months, use a neutral cleaner followed by a protective coating or polish. This adds another barrier against pollutants.

-

Annual assessment — For outdoor structures, check weld seams, joints, and hidden corners. These are the most vulnerable areas because moisture tends to sit longer.

-

Immediate action — If you spot a rust spot, clean it right away with a non-abrasive cleaner. Small spots are easy to fix, but ignored ones spread fast.

A good example comes from coastal buildings. Engineers discovered that railings cleaned every two weeks and inspected quarterly lasted twice as long compared to those left untouched for months. That’s the difference between replacing panels after 15 years versus enjoying them for 30.

4. Applications and Expected Lifespan in Different Settings

4.1 Kitchenware and household items

Stainless steel has become a kitchen favorite because it resists stains, smells, and bacteria. Think of cookware, cutlery, and sinks — these are places where heat, moisture, and food acids constantly collide. A well-made Stainless Steel Sheet pressed into a sink can last over 30 years if you follow simple care habits.

The durability depends on three things:

-

Heat cycles — Pots and pans heat up and cool down daily. Good-quality 304 stainless handles this without warping, unlike cheaper alloys.

-

Cleaning routine — Most households scrub pans aggressively, but using nylon pads instead of steel wool makes a big difference. Scratches shorten the shine and open the door to tea-staining.

-

Exposure to acids — Tomato sauce, vinegar, and lemon juice are acidic. If you let them sit too long, they dull the surface. Quick rinsing avoids that.

Studies from food-grade equipment labs show stainless cutlery often remains functional for 25+ years, while sinks and countertops often last 40–50 years with proper cleaning. Many professionals point out that stainless doesn’t just resist damage; it also looks modern even after decades, which is why it dominates kitchenware.

4.2 Architectural and structural uses

In construction, stainless steel isn’t just about looks — it’s about endurance. Skyscrapers, bridges, and modern facades use it to fight off weather, pollution, and temperature swings. For instance, architectural panels made from Stainless Steel Products easily outlast painted metals, which need recoating every 10 years.

Different structural roles affect lifespan:

-

Indoor cladding in airports and shopping centers can stay flawless for 60+ years, because it never faces rain or salt.

-

Exterior facades in urban areas usually last 30–40 years before showing minor discoloration, especially near traffic pollution.

-

Bridges and public sculptures built with high-chromium stainless still look sharp after 70 years, with minimal maintenance.

A famous example is the Chrysler Building’s stainless steel crown in New York. Installed in 1930, it still shines after nearly a century, proving how well the alloy holds up in architecture.

The secret is consistent upkeep: wash with fresh water a few times per year and inspect welds. Compared to carbon steel structures, which often need repainting and anti-rust treatments every decade, stainless offers a far lower lifetime cost.

4.3 Marine and industrial environments

Saltwater, humidity, and heavy chemicals are the toughest challenges for stainless steel. In these environments, 304 stainless still performs well, but engineers often prefer 316 stainless because its molybdenum content boosts resistance to chloride attack. However, in less aggressive zones like interior ship cabins, 304 can last 20–25 years without issue.

In marine engineering, where decks, railings, and fittings face direct spray, maintenance makes the difference:

-

Rinse with fresh water weekly to wash away salt deposits.

-

Inspect every three months for tiny pitting spots.

-

Apply protective coatings once or twice a year.

For industrial uses — think food processing plants, breweries, or chemical factories — stainless steel is chosen because it resists cleaning agents and high heat. Equipment made from 304 can last 25–35 years, and sometimes longer, depending on exposure. Researchers from the European Stainless Steel Development Association note that even in highly acidic processing lines, proper cleaning extends service life by at least 10 years.

Expected Lifespan of 304 Stainless Steel in Different Applications

| Application Setting | Typical Lifespan (Years) | Key Maintenance Needs |

|---|---|---|

| Kitchenware (pots, cutlery, sinks) | 25–50 | Regular cleaning, avoid harsh abrasives |

| Indoor architectural cladding | 60+ | Occasional dusting and water rinsing |

| Outdoor facades (urban) | 30–40 | Fresh water rinses, pollution cleaning |

| Public sculptures / bridges | 70+ | Annual inspections, weld checks |

| Marine interiors (cabins, fittings) | 20–25 | Freshwater rinsing, quarterly checks |

| Industrial plants (food, chemical) | 25–35 | Cleaning after chemical exposure |

Brands like pvdstainlesssteel supply custom stainless solutions for both marine and industrial clients, emphasizing inspection schedules because no metal, not even stainless, can fully ignore marine_engineering stress or industrial-scale chemical exposure.

For more detailed insights on the lifespan and maintenance of PVD coated stainless steel, visit our comprehensive guide: What is a PVD stainless steel sheet?