When choosing stainless steel elevator door panels, consider both material and finish. PVDStainlessSteel offers high-quality elevator panels in 304 and 316 grades, with durable brushed, mirror, or PVD-coated finishes. Their custom solutions ensure a perfect fit, long-lasting durability, and sleek design for commercial or residential buildings, making them a reliable choice for any project.

1.Material Types and Grades

1.1 Common Stainless Steel Grades (304 vs 316)

When selecting stainless steel elevator doors, understanding the material grade is crucial. The two most common grades are 304 en 316 stainless steel. Grade 304 is widely used for general applications, offering excellent corrosion resistance and affordability. On the other hand, 316 RVS contains molybdenum, which significantly improves resistance to harsh environments such as coastal or chemical-heavy areas.

For example, in a high-rise condominium in Miami, our premium stainless elevator panels made with 316 stainless steel were chosen specifically to resist saltwater corrosion while maintaining a polished look that complements the modern lobby design.

Here’s a quick comparison of the key differences:

| Eigenskip | 304 Stainless Steel | 316 RVS |

|---|---|---|

| Corrosie Resistance | High (general environments) | Very High (saltwater & harsh chemicals) |

| Strength | Strong | Slightly stronger |

| Kosten | Moderate | Higher |

| Common Use | Indoor, moderate traffic | Outdoor, coastal, high-humidity |

1.2 Differences in Durability and Corrosion Resistance

Durability is not just about how thick the metal is. It also involves resistance to scratches, dents, and environmental wear. For elevators in commercial buildings, traffic can be intense, with doors opening hundreds of times per day. Using our stainless steel solutions ensures that panels remain pristine even in busy environments.

In office towers in New York City, we installed high-traffic elevator doors in 304 stainless steel. Despite daily use, the panels maintained their structural integrity and visual appeal for years, demonstrating that proper grade selection is essential for long-term durability.

1.3 Surface Finish Options (Brushed, Mirror, Hairline)

The finish of stainless steel elevator doors impacts both aesthetics and maintenance. Common finishes include:

-

Brushed Finish – Offers a matte look with fine lines, concealing minor scratches and fingerprints. Ideal for lobbies where a subtle, modern look is preferred.

-

Mirror Finish – Highly reflective and sleek, perfect for luxury buildings. However, it requires more frequent cleaning to maintain its shine.

-

Hairline Finish – Similar to brushed but with longer, linear patterns, giving a sophisticated, contemporary feel.

In a boutique hotel in Los Angeles, our high-quality stainless steel doors with hairline finish were installed in all guest elevators. The finish not only enhanced the modern interior design but also reduced the visible wear from constant use.

When selecting the finish, consider both the building’s design and the maintenance level your team can commit to. A well-chosen finish ensures that the stainless steel elevator doors look fresh and premium, even in high-traffic areas.

2.Design and Aesthetic Considerations

2.1 Panel Style and Patterns

When choosing elevator door panels, the style and pattern can define the building’s first impression. Stainless steel doors can be sleek and minimalist, feature geometric patterns, or incorporate artistic etchings.

For instance, in a contemporary office building in Chicago, our high-quality stainless steel doors featured a subtle linear pattern that complemented the glass and steel lobby. The panels not only enhanced the modern aesthetic but also hid fingerprints and minor scratches effectively.

Common panel options include:

-

Flat Panels – Smooth, reflective surfaces suitable for minimalist designs.

-

Textured Panels – Brushed, patterned, or embossed finishes that add depth.

-

Custom Etched Designs – Logos, abstract patterns, or architectural motifs tailored for branding or unique interiors.

2.2 Color and Coating Choices

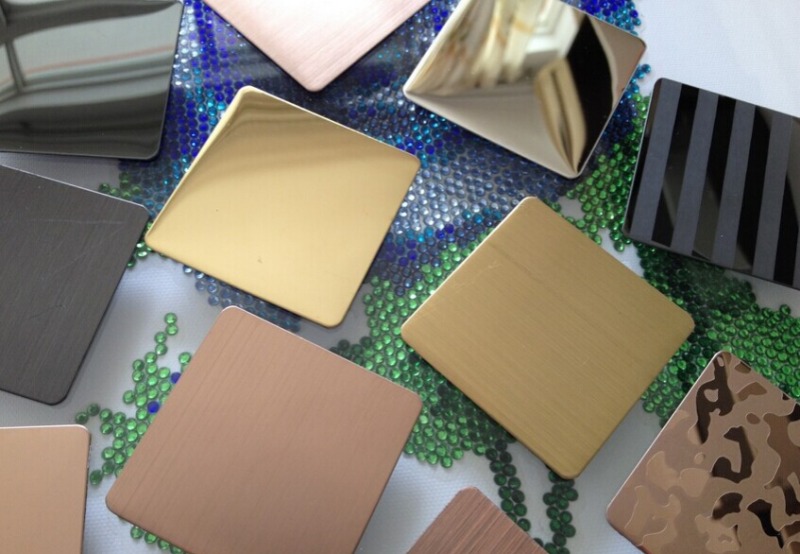

While stainless steel naturally comes in a silver tone, various coatings and color treatments allow for a broader design palette. PVD (Physical Vapor Deposition) coatings, for example, can produce gold, bronze, or black finishes while maintaining the metal’s durability.

Here’s a comparison of common stainless steel finishes:

| Finish Type | Appearance | Duorsumens | Ideal Use |

|---|---|---|---|

| Geborsteld | Matte lines, subtle reflection | High, hides scratches | Office and commercial buildings |

| Mirror | High-gloss reflective | Moderate, shows fingerprints | Luxury hotels or high-end condos |

| PVD Color Coating | Gold, Bronze, Black | Very high, corrosion-resistant | Custom designs, branded interiors |

In a high-end residential project in San Francisco, our premium stainless panels were coated in a dark bronze PVD finish. The result was an elevator lobby that felt both luxurious and contemporary, while the coating resisted wear from heavy daily use.

2.3 Matching Elevator Interiors

A crucial factor often overlooked is how elevator doors integrate with the rest of the interior. Materials like glass, wood veneer, or stone accents can be complemented by the right stainless steel finish.

Steps to achieve harmony:

-

Assess Lobby Materials – Identify predominant textures and colors.

-

Choose Complementary Panel Finish – Match or contrast wisely for a balanced look.

-

Consider Hardware and Trim – Handles, frames, and control panels should align with door aesthetics.

In a boutique hotel in Los Angeles, our elevator door panels in brushed stainless steel paired perfectly with walnut veneer walls and polished stone floors, creating a cohesive design that impressed both guests and staff.

Dimensions and Fit

3.1 Standard vs Custom Sizes

Choosing the correct size for stainless steel elevator doors is crucial for both functionality and aesthetics. Standard sizes are convenient because they fit most commercial elevator shafts and reduce lead time, but they can be limiting for unique building designs. Custom sizes, on the other hand, allow full flexibility, ensuring a perfect fit for non-standard elevators or historic buildings with irregular dimensions.

For example, in a boutique hotel in Boston, the elevator shafts were slightly narrower than modern standards. Our team designed custom stainless steel elevator panels that matched the exact dimensions while maintaining consistent panel thickness and alignment with the lobby walls. This avoided costly retrofitting or interior modifications and created a seamless, professional finish.

Steps to determine the right size:

-

Measure the height and width of the elevator shaft precisely at multiple points.

-

Identify any structural irregularities, such as slanted walls or protruding trim.

-

Decide whether a standard panel can accommodate these variations or if a custom panel is necessary.

3.2 Thickness and Weight Considerations

The thickness of stainless steel panels affects both durability and operation. Thicker panels resist dents, scratches, and long-term wear, but they are heavier, which can influence the elevator’s mechanical performance. Lighter panels reduce strain on the door operators and can improve energy efficiency, but may be less resistant to high traffic impacts.

| Parameter | Typical Range | Benefits | Considerations |

|---|---|---|---|

| Panel Thickness | 1.0–2.0 mm | Higher durability, better impact resistance | Heavier, may need stronger door mechanisms |

| Panel Weight | 50–90 kg per panel | Solid feel, premium appearance | Installation requires reinforced supports |

| Door Operator Compatibility | N/A | Ensures smooth opening/closing | Must match panel weight with elevator motor capacity |

In a corporate office building in New York, we installed 1.5 mm thick premium stainless panels for a high-traffic elevator. The panels provided excellent durability without overloading the door motors, resulting in smooth, long-lasting operation even with hundreds of daily cycles.

3.3 Compatibility with Existing Elevator Doors

When upgrading or replacing elevator doors, compatibility is a major concern. Doors must align perfectly with existing frames, guides, and locking mechanisms. Misalignment can cause operational issues, increased wear, or safety risks.

Practical steps to ensure compatibility:

-

Inspect the existing door frame, tracks, and guide rails for dimensions and wear.

-

Confirm that the new stainless steel panels match the original opening width and height with minimal tolerance adjustments.

-

Verify that the locking mechanism and door sensors align correctly with the new panels.

-

Conduct a test installation before final delivery to ensure seamless operation.

In a high-rise residential project in Chicago, our high-quality elevator door panels were installed on an older elevator system. By carefully measuring and fabricating the panels to match the existing frames, the installation team avoided any structural modifications, saving the client both time and cost while delivering a modern, durable finish.

Maintenance and Longevity

4.1 Cleaning Requirements

Proper cleaning is essential to maintain the appearance and performance of stainless steel elevator doors. Unlike painted or laminated doors, stainless steel is resistant to stains and corrosion, but regular maintenance prevents fingerprints, smudges, and environmental grime from building up.

Best practices include:

-

Use a soft microfiber cloth or sponge with mild soap and warm water. Avoid abrasive pads or harsh chemicals that can scratch the surface.

-

For tougher stains or fingerprints, a specialized stainless steel cleaner can be applied, followed by wiping in the direction of the grain to maintain the finish.

-

High-traffic areas, like office buildings or hotels, may require daily wiping, while lower-traffic locations can follow a weekly routine.

In a luxury office complex in San Francisco, our PVDStainlessSteel products were installed in all elevators. The property management team found that following a simple cleaning schedule preserved the doors’ mirror finish for years without needing replacement or refinishing.

4.2 Resistance to Scratches and Wear

Durability goes beyond thickness—it’s about resisting everyday wear from people, luggage, and carts. Brushed and hairline finishes are particularly effective at concealing minor scratches, while mirror finishes may require more frequent upkeep.

A practical way to evaluate resistance:

-

Brushed Finish: Minimizes visible scratches; ideal for office and commercial use.

-

Mirror Finish: Highly reflective but prone to showing marks; suited for luxury or low-traffic settings.

-

PVD-Coated Panels: Extremely resistant to wear, corrosion, and fading, maintaining both color and texture over time.

In a busy convention center in Chicago, our high-traffic premium stainless panels were installed. Despite thousands of daily entries, the panels showed minimal wear after several years, proving that investing in the right grade and finish pays off in longevity.

4.3 Long-Term Cost vs Quality

When choosing elevator panels, initial cost is only part of the picture. Higher-quality stainless steel elevator doors may cost more upfront but can significantly reduce maintenance, repairs, and replacement expenses over time.

Considerations for long-term value:

-

Material Grade: 316 stainless steel offers superior corrosion resistance, especially in coastal or humid environments, extending service life.

-

Finish Type: Durable finishes like brushed or PVD coatings minimize visible wear, reducing cleaning and refinishing costs.

-

Installation Quality: Proper fitting and alignment prevent operational strain, avoiding costly adjustments.

A commercial complex in Miami chose 316 stainless steel with a brushed finish from our high-quality stainless steel doors. While the upfront cost was higher than standard 304 panels, the long-term savings in maintenance and replacements made it a smarter investment, especially given the heavy daily usage.

Shortlist ready? Compare sizes, colors & hardware options in our stainless steel elevator door panels catalog and request a free quote today.