Bidh stàilinn gun smal le còmhdach PVD a’ lìbhrigeadh strì an aghaidh sgrìoban 6-10× agus dìon nas fheàrr bho chreimeadh.Bidh stàilinn gun smal le còmhdach PVD a’ lìbhrigeadh strì an aghaidh sgrìoban 6-10× agus dìon nas fheàrr bho chreimeadh.

An Saidheans air Cùl Còmhdach PVD

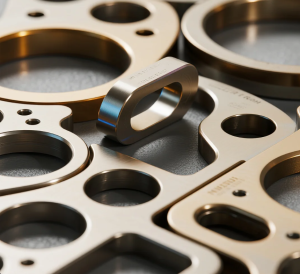

Sealladh farsaing air a’ phròiseas còmhdach PVD

’S e pròiseas adhartach a th’ ann am pròiseas Tasgadh Ceò Corporra (PVD) a thathas a’ cleachdadh gus stàilinn gun smal a leasachadh, a’ tabhann leasachaidhean mòra ann an seasmhachd, strì an aghaidh creimeadh, agus tarraingeachd bòidhcheadBidh e a’ tòiseachadh le bhith a’ falmhachadh stuth cruaidh taobh a-staigh seòmar falamh, an uairsin a’ dlùthadh a’ cheò air an t-substrate stàilinn gun smal, a’ cruthachadh sreath uachdar seasmhach, cruaidh agus ceangailte gu teann.

Am prìomh fheart ann an soirbheachas an Pròiseas còmhdach PVD ’S e an àrainneachd fo smachd taobh a-staigh seòmar falamh. Tha am pròiseas a’ gabhail àite fo cuideam ìosal, mar as trice eadar 10^-3 gu 10^-5 torr, a leigeas leis an stuth air a ghalachadh siubhal agus socrachadh gu cothromach air uachdar an stàilinn gun smal. Tha an ìre àrd de chruinneas san àrainneachd seo a’ dèanamh cinnteach gu bheil Tha còmhdach PVD ceangailte gu teann chun uachdar aig ìre atamach, a’ toirt seachad barrachd strì an aghaidh caitheamh, creimeadh, agus sgrìoban.

Seo geàrr-chunntas air na prìomh cheumannan a tha an sàs ann Stàilinn gun staoin le còmhdach PVD:

-

Suidheachadh Seòmar FalamhTha an stàilinn gun smal air a chur taobh a-staigh seòmar falamh far a bheil cuideam an adhair air a lùghdachadh gus dèanamh cinnteach gum faod an stuth a tha air a ghalachadh siubhal gu saor agus gu cothromach. Tha an àrainneachd falamh seo deatamach airson na toraidhean còmhdachaidh as fheàrr fhaighinn.

-

Falmhachadh StuthanA stuth targaid (leithid titanium no sirconium) air a theasachadh gu teòthachd àrd, gu tric nas àirde na 2000°C, ag adhbhrachadh gun tèid e a ghalachadh. Tha an stuth seo an uair sin air a stiùireadh air uachdar an stàilinn gun smal.

-

Tasgadh CòmhdachBidh na mìrean smùidichte a’ socrachadh air an t-substrate stàilinn gun smal, far am bi iad a’ ceangal aig ìre atamach, a’ cruthachadh còmhdach tana ach gu math seasmhach.

-

Fuarachadh agus cruadhachadhÀs dèidh a’ phròiseis tasgaidh, bidh an seòmar air fhuarachadh mean air mhean. Bidh am pròiseas fuarachaidh seo a’ cruadhachadh a’ chòtaidh, a’ dèanamh cinnteach gu bheil e ceangailte gu daingeann ris an stàilinn gun smal.

Càileachd a’ chòmhdaich Tha buaidh mhòr aig purrachd nan stuthan a thathar a’ cleachdadh agus an smachd mionaideach air teòthachd, cuideam agus ùine tasgaidh air seo. Chan e a-mhàin gun leasaich còmhdach PVD àrd-inbhe feartan an uachdair ach cuideachd gun àrdaich e fad-beatha iomlan an stàilinn gun smal, ga dhèanamh freagarrach airson tagraidhean dùbhlanach.

Buannachdan còmhdach PVD air stàilinn gun smal

Tha an còmhdach PVD a’ toirt seachad stàilinn gun smal feartan air leth nach urrainn dha còtaichean traidiseanta a bhith co-ionnan riutha idir. Seo coimeas eadar prìomh fheartan eadar Còmhdach PVD agus dòighean còmhdaich cumanta eile:

| Property | Còmhdach PVD | Electroplating | Còmhdach Pùdar |

|---|---|---|---|

| Cruas | 2000-3000 each-chumhachd | 300-500 each-chumhachd | 400-800 each-chumhachd |

| Frith-aghaidh creimeadh | Sàr-mhath | Meadhanach | Math |

| Temperature Resistance | Suas ri 500°C | Suas gu 150°C | Suas gu 250°C |

| Neart Greamachaidh | Glè Àrd | Meadhanach | Math |

| Seasmhachd | Glè Àrd | Meadhanach | High |

| Cosgais | $2-$6 gach m² | $1-$3 gach m² | $0.5-$2 gach m² |

PVD coatings gu math nas fheàrr na dòighean traidiseanta ann an cruas, strì an aghaidh teòthachd, agus dìon creimeadhLe cruas de 2000-3000 each-chumhachd, PVD coatings uachdaran a chruthachadh a tha air leth dìonach an aghaidh sgrìoban agus caitheamh, gan dèanamh freagarrach airson tagraidhean a dh’ fheumas seasmhachd fad-ùine.

Còmhdach PVD airson stàilinn gun smal a’ leasachadh gu mòr an aghaidh creimeadh agus dìon bho sgrìoban. Tha am pròiseas seo foirfe airson elevator door panels, stàilinn gun smal ailtireachd, agus aplacaidean eile le trafaic àrd.

Tha an strì an aghaidh creimeadh Tha stàilinn gun smal còmhdaichte le PVD cuideachd air leth math, oir tha e a’ dìon an aghaidh àrainneachdan cruaidh, a’ gabhail a-steach nochdadh do salainn, aigéid, agus suidheachaidhean sìde anabarrach. Stàilinn gun smal còmhdaichte le PVD Tha co-phàirtean gu sònraichte buannachdail ann an gnìomhachasan leithid aerospace, càraichean, agus innealan meidigeach, far a bheil seasmhachd agus coltas an dà chuid deatamach.

Prìomh Bhuannachdan Còmhdach PVD

-

Seasmhachd Caitheamh LeasaichteFaodaidh còmhdach PVD leasachadh mòr a dhèanamh air strì an aghaidh caitheamh, a’ dèanamh stàilinn gun smal nas comasaiche seasamh an aghaidh suathadh agus sgrìobadh cunbhalach. Tha an fheart seo gu sònraichte cudromach ann an tagraidhean àrd-chaitheamh, leithid pàirtean innealan neo innealan.

-

Tarraingeachd bòidhchead nas fheàrrEu-coltach ri còtaichean traidiseanta, faodaidh PVD raon de rudan a chur ris dathan agus crìochnachaidhean gu stàilinn gun smal, leithid òr, umha, no eadhon dubh. Tha seo ga dhèanamh Stàilinn gun smal còmhdaichte le PVD mòr-chòrdte ann an gnìomhachasan mar bathar sòghail, seudaireachd, agus dealbhadh ailtireil.

-

Seasmhachd Àrainneachdail nas FheàrrBidh an còmhdach cuideachd a’ leasachadh gu mòr an strì an stuth an aghaidh factaran àrainneachdail, a’ gabhail a-steach teas, taiseachd, agus rèididheachd UV, a nì cinnteach gum fuirich càileachd agus coltas bòidhchead an stuth slàn eadhon an dèidh dha a bhith fosgailte do chumhachan dùbhlanach airson ùine mhòr.

-

Fad-beatha nas fhaide agus èifeachdas cosgais: PVD coatings leudaich fad-beatha phàirtean stàilinn gun smal le bhith gan dìon bho caitheamh agus creimeadh, a’ lughdachadh chosgaisean ath-chur mu dheireadh. Sgrùdaidhean seall sin Toraidhean còmhdaichte le PVD mu dheireadh suas ri 10 tursan nas fhaide na toraidhean stàilinn gun smal gun làimhseachadh, a’ lughdachadh an iomlan cosgais seilbh.

Carson a thaghas tu sinn airson stàilinn gun smal le còmhdach PVD?

Aig PVD Stainless Steel, tha sinn a’ tabhann seirbheisean còmhdach PVD den ìre as àirde a leasaicheas seasmhachd, bòidhchead agus coileanadh do thoraidhean stàilinn gun smal. Seo beagan adhbharan carson a bu chòir dhut earbsa a chur annainn le na feumalachdan còmhdach PVD agad:

-

Saothrachadh ProifeiseantaLe 15 innealan ann an obrachadh agus comas de 14,000 meatair ceàrnagach gach latha, bidh sinn a’ dèanamh cinnteach gu bheil na h-òrdughan agad air an crìochnachadh Ann an àm agus le mionaideachd.

-

Meudan Òrdugh as ìsle sùbailteMa tha an sònrachadh a dh’ fheumas tu againn ann an stoc, is urrainn dhuinn meud òrdugh sam bith a choileanadh - mòr no beag.

-

Smachd Càileachd TeannTha na còtaichean againn a rèir nan riatanasan ISO 9001:2008, and we utilize the best materials, including PPG agus KYNAR500 coatings.

-

Reliable Shipping Partners: We offer competitive shipping rates through our trusted partners, ensuring your products reach you promptly and safely.

-

Seirbheisean OEM: We offer a wide range of decorative patterns and can process according to your specific designs. Let us know your requirements and we’ll make it happen.

By choosing PVD Stainless Steel for your PVD coating needs, you are investing in products that offer superior performance, durability, and aesthetic appeal, ensuring long-lasting satisfaction.

Types of PVD Coating and Their Durability

Physical Vapor Deposition (PVD) Variants

Physical Vapor Deposition (PVD) is a versatile coating process used to improve the properties of materials like stainless steel. It involves vaporizing a solid material in a vacuum and allowing it to condense onto the target substrate. The main types of PVD coatings include Cathodic Arc Deposition (CAD), Magnetron Sputtering, Evaporation Deposition, agus Ion Plating, each offering distinct advantages in terms of durability, appearance, and application.

-

Cathodic Arc Deposition (CAD): This is one of the most widely used PVD processes. During CAD, a high voltage is applied to a metal target, causing it to ionize and form a vapor, which is then deposited onto the stainless steel surface. This process produces coatings that are extremely hard agus highly resistant to wear and corrosion. Typically, CAD coatings are used in high-stress applications, such as cutting tools neo aerospace components. Hardness values for CAD coatings can range between 2200 to 3000 HV (Vickers hardness), making them suitable for extreme environments.

-

Magnetron Sputtering: This process involves applying a magnetic field to accelerate ions towards a target, causing the target material to sputter and form a vapor that deposits on the surface. Magnetron sputtering is known for its uniform coating agus excellent control over thickness. Coatings produced by this method have moderate hardness, typically around 1000 to 2000 HV. These coatings are well-suited for decorative applications agus electronic components, as they provide an attractive finish along with solid durability.

-

Evaporation Deposition: This method involves heating a solid metal source until it evaporates, and then allowing the vapor to condense on the substrate. The key benefit of evaporation deposition is its ability to coat large areas uniformly, making it suitable for thin coatings. The hardness of these coatings is generally lower than other methods, typically ranging from 500 to 1000 HV. This makes it less ideal for high-wear applications but useful for protective layers in electronics agus optical coatings.

-

Ion Plating: Ion plating uses an ionized vapor to deposit a thin, hard layer onto the target material. The coating produced by ion plating is characterized by its high adhesion strength agus superior resistance to corrosion. Ion plating is often used in aerospace agus càraichean applications due to its high hardness (typically 2000 to 2500 HV) and thermal resistance. It can also produce coatings in various colors, making it popular for decorative finishes.

How Different Types Impact Durability

The durability of PVD coatings can vary significantly depending on the type of PVD process and the stuth used. Each variant affects the adhesion strength, wear resistance, agus strì an aghaidh creimeadh of the final product, which ultimately impacts how long the coating will last in real-world applications.

-

Cathodic Arc Deposition (CAD): CAD coatings are among the most durable and hard-wearing. Due to the high-energy environment in CAD, the resulting coatings are extremely resistant to scratches, wear, agus abrasion, making them perfect for high-performance environments like cutting tools, medical implants, agus aerospace parts. The coatings typically last up to 10 times longer than untreated stainless steel in abrasive conditions, as they form a dense, non-porous layer. This high hardness helps prevent the degradation of stainless steel surfaces in environments where other coatings may fail prematurely.

-

Magnetron Sputtering: Coatings produced by magnetron sputtering offer good durability for general applications but are not as hard as CAD coatings. They typically feature moderate hardness (1000-2000 HV) and perform well in light to moderate wear conditions, such as in electronics agus decorative finishes. Magnetron sputtered coatings provide high-quality finishes with excellent color retention and resistance to corrosion. However, compared to CAD coatings, they have a shorter lifespan in high-stress applications, such as automotive or industrial machinery.

-

Evaporation Deposition: Coatings formed through evaporation deposition offer the lowest hardness of all the PVD variants, ranging from 500 to 1000 HV. These coatings are ideal for thin, protective layers and are widely used in optical coatings agus electronics. While they do provide a level of corrosion resistance, their durability in wear-heavy environments is limited. Evaporated coatings will likely wear off faster than CAD or sputtered coatings, especially under high-friction neo abrasive conditions. However, for applications requiring fine coatings over large areas, such as decorative finishes neo reflective surfaces, evaporation deposition remains an excellent choice.

-

Ion Plating: Ion plated coatings offer a unique combination of high hardness and superior adhesion strength, making them ideal for aerospace agus automotive applications. The coating’s wear resistance agus strì an aghaidh creimeadh are significantly better than those produced by evaporation deposition and magnetron sputtering. Ion-plated surfaces also have a high thermal resistance, which makes them suitable for extreme temperatures. They can last for several years in high-temperature environments without significant degradation. The seasmhachd of ion-plated coatings is especially useful for parts exposed to heat cycling, friction, agus chemical exposure.

Here is a comparison of the durability factors across the different PVD variants:

| PVD Variant | Hardness (HV) | Wear Resistance | Frith-aghaidh creimeadh | Tagraidhean àbhaisteach |

|---|---|---|---|---|

| Cathodic Arc Deposition | 2200-3000 HV | Sàr-mhath | Sàr-mhath | Cutting tools, aerospace, medical implants |

| Magnetron Sputtering | 1000-2000 HV | Math | Math | Electronics, decorative coatings |

| Evaporation Deposition | 500-1000 HV | Meadhanach | Meadhanach | Optical coatings, decorative finishes |

| Ion Plating | 2000-2500 HV | Glè Àrd | Sàr-mhath | Aerospace, automotive, high-stress parts |

In terms of overall durability, Cathodic Arc Deposition (CAD) offers the highest resistance to both caitheamh agus creimeadh, making it suitable for heavy-duty industrial and mechanical applications. On the other hand, magnetron sputtering agus ion plating provide good durability but may not perform as well in extreme environments where abrasion agus high temperatures are prevalent. Evaporation deposition serves best for applications that require thin, uniform coatings, but it should not be relied upon in high-wear situations.

The choice of PVD variant largely depends on the specific needs of the application, a’ gabhail a-steach environmental exposure, performance requirements, agus cost considerations. Each method has its own set of trade-offs in terms of coating hardness, adhesion strength, agus cost, making it crucial to select the right variant based on the intended use.

The Role of Thickness in Durability

How Coating Thickness Affects Strength

Tha an thickness of a PVD coating plays a crucial role in determining the strength agus overall durability of the coated stainless steel. The thicker the coating, the more it can withstand environmental stress, wear, and corrosion. However, thicker coatings may not always equate to better performance, as there are limits to the benefits gained from increasing coating thickness.

-

Increased Thickness = Higher Hardness: As the thickness of the coating increases, its cruas generally improves, which makes the surface more resistant to scratching agus abrasion. For instance, a Còmhdach PVD with a thickness of 2-3 microns can have a Vickers hardness (HV) of around 1500-2000. Increasing the coating thickness to 5 microns or more may push the hardness up to 2200-3000 HV, providing a surface that can withstand much harsher wear conditions.

-

Impact on Corrosion Resistance: Thicker coatings also tend to enhance the strì an aghaidh creimeadh of the substrate. This is because a thicker layer acts as a more effective barrier against corrosive elements like water, salts, and acids. For example, a 2-micron coating may offer good resistance, but a 5-micron neo 10-micron layer can provide more complete protection, especially in harsh, industrial environments where exposure to chemicals is frequent.

-

Reduced Adhesion at Extreme Thicknesses: While thicker coatings offer more protection, they can also pose a risk in terms of adhesion to the stainless steel substrate. As the coating grows thicker, there’s a higher possibility that the bond between the coating and the substrate will weaken, especially if the deposition process isn’t carefully controlled. Typically, coatings above 10 microns tend to show a slight reduction in adhesion strength, which can lead to premature coating failure if exposed to high mechanical stress.

In summary, PVD coating thickness is directly related to both the cruas agus strì of the coated surface. However, there are trade-offs between coating thickness and other factors like adhesion strength agus cost.

Optimal Thickness for Maximum Durability

Tha an optimal thickness for PVD coatings largely depends on the specific application and environment in which the coated stainless steel will be used. There is a balance between achieving maximum durability and avoiding unnecessary costs neo coating failure.

-

General Guidelines for Thickness:

-

Light to Moderate Wear: For applications like decorative finishes, electronics, agus innealan meidigeach, a coating thickness of 1-2 microns is often sufficient. At this thickness, the Còmhdach PVD provides a good combination of appearance agus protection, without excessive cost.

-

Heavy Wear and Corrosive Environments: For components subjected to high wear, abrasive conditions, or harsh chemicals, 3-5 microns is considered optimal. Coatings in this range provide the best balance of seasmhachd agus adhesion, ensuring the material lasts longer without becoming too brittle.

-

Extreme Conditions: For environments with extreme wear, such as cutting tools, aerospace, or high-performance automotive parts, coatings as thick as 10 microns may be necessary. These coatings provide maximum hardness agus strì an aghaidh creimeadh, but it’s crucial to ensure that the bonding process is controlled to prevent delamination.

-

-

Effect on Performance: Thickness directly impacts the performance characteristics of the coating. A thicker coating will generally increase the wear resistance agus strì an aghaidh creimeadh, but beyond a certain point, the performance improvement may plateau. For instance, increasing the thickness from 2 microns gu 5 microns might provide a noticeable improvement in durability, but increasing it to 10 microns may offer diminishing returns in some applications.

-

Cost vs. Benefit: It’s important to consider cost-effectiveness when choosing the thickness. Stàilinn gun staoin le còmhdach PVD is typically priced by the square meter, with thicker coatings costing more. The trade-off between the extra cost of thicker coatings and the additional durability they provide should be carefully considered based on the intended use. For instance, cutting tools used in heavy-duty applications may justify the extra cost of a 5-micron coating, whereas decorative components may only need a 2-micron coating to achieve sufficient performance.

Here’s a breakdown of the typical thickness ranges and their applications:

| Coating Thickness | Hardness (HV) | Frith-aghaidh creimeadh | Tagraidhean àbhaisteach |

|---|---|---|---|

| 1-2 microns | 1000-1500 HV | Meadhanach | Decorative finishes, electronics, innealan meidigeach |

| 3-5 microns | 1500-2500 HV | High | Aerospace, càraichean, industrial parts |

| 5-10 microns | 2500-3000 HV | Sàr-mhath | Cutting tools, high-stress machinery, high-performance automotive parts |

PVD coatings with a thickness between 3 to 5 microns are generally considered optimal for achieving a balance of durability, cost-effectiveness, agus performance. These coatings provide sufficient protection for most industrial, mechanical, and decorative applications without excessive thickness that could lead to unnecessary costs.

When deciding on the optimal thickness for a given application, you should consider environmental conditions, wear expectations, agus an required performance. For most general-purpose applications, a 3-5 micron PVD coating offers the best combination of durability, cost, and material performance.

Environmental Resistance and PVD Coated Stainless Steel

Resistance to High Temperatures

One of the standout features of Stàilinn gun smal còmhdaichte le PVD is its exceptional resistance to high temperatures. PVD coatings, depending on the material used, can withstand temperatures that would degrade most untreated materials. This property makes Stàilinn gun smal còmhdaichte le PVD ideal for industries where components are subjected to extreme heat, such as aerospace, càraichean, agus industrial manufacturing.

-

Thermal Stability of PVD Coatings: PVD coatings are generally known to maintain their structural integrity up to temperatures of 500°C to 600°C. Some specific coatings, such as Titanium Nitride (TiN) neo Chromium Nitride (CrN), can even resist temperatures as high as 900°C without significant degradation of their properties. This is crucial for parts exposed to constant heat cycles, like engine components, turbine blades, or high-performance tools.

-

Thermal Expansion Compatibility: Stainless steel and its PVD coatings are well-matched in terms of thermal expansion. This ensures that as the temperature fluctuates, the coating expands and contracts in sync with the substrate. If the coating and the substrate expand at significantly different rates, the coating can crack or peel off, compromising its effectiveness. For Stàilinn gun smal còmhdaichte le PVD, this thermal compatibility ensures that the coating remains intact over long periods, even in environments with frequent temperature fluctuations.

-

Heat-Resistant Coating Thickness: The thickness of the PVD coating can influence its thermal resistance. For instance, thicker coatings (e.g., 5 microns or more) tend to perform better under high temperatures, as the added thickness helps dissipate heat and maintain the surface integrity. Thicker coatings also offer more substantial protection against thermal shock.

Tha an high-temperature resistance of Stàilinn gun smal còmhdaichte le PVD makes it an essential material in applications exposed to heat, ensuring components perform reliably without showing signs of wear or degradation.

Resistance to Chemical Exposure

Another key benefit of Stàilinn gun smal còmhdaichte le PVD is its ability to withstand chemical exposure without degrading. This quality is particularly important for industries that deal with corrosive environments, such as chemical processing, marine environments, agus food processing. PVD coatings provide a protective barrier that shields the underlying stainless steel from the damaging effects of harsh chemicals.

-

Corrosion Resistance from PVD Coatings: The PVD process imparts a dense, non-porous layer to stainless steel, significantly enhancing its ability to resist corrosive substances. Coatings like TiN agus CrN offer excellent resistance to acids, alkalis, agus chlorides, making them ideal for parts exposed to industrial chemicals neo saltwater environments.

-

Chemical Compatibility: PVD coatings offer superior resistance to chemical agents compared to traditional coatings like electroplating neo paint. PVD coatings are inert to most organic solvents, acids, agus alkalis, and will maintain their integrity even in the presence of highly corrosive substances. For example, TiN coatings are resistant to hydrochloric acid (HCl) agus sulfuric acid (H2SO4), while CrN coatings excel in resisting alkaline solutions.

-

Protective Barrier: The non-porous nature of PVD coatings means that they act as an effective barrier against the penetration of harmful chemicals. This is especially useful for parts that are in constant contact with aggressive substances like detergents, pesticides, or industrial cleaning agents. By preventing these substances from reaching the stainless steel surface, the PVD coating prolongs the lifespan of the component and ensures its long-term reliability.

-

Wear Resistance in Chemical Environments: PVD coatings don’t just resist chemicals, they also offer wear resistance, which is vital in harsh chemical environments where components may be subject to both abrasion agus chemical exposure. For instance, PVD-coated valves agus pumps used in chemical processing plants are protected against both abrasion from fluids agus corrosion from aggressive chemicals, ensuring that they perform for extended periods without failure.

Stàilinn gun smal còmhdaichte le PVD offers an excellent combination of chemical resistance, seasmhachd, agus thermal stability, making it a reliable choice for environments exposed to corrosive substances. The robust chemical resistance ensures that parts remain functional and aesthetically pleasing for much longer than untreated materials, even in harsh conditions.

For further information about Stàilinn gun staoin le còmhdach PVD, you can visit PVD Stainless Steel Products, where we provide high-quality, durable stainless steel solutions designed to withstand extreme environments and harsh chemical exposures.

Also see: What is a PVD stainless steel sheet?