Choosing the best stainless steel elevator doors starts with selecting the right grade and finish. For busy hotel lobbies, 304 or 316 stainless steel panels with brushed or PVD coatings offer durability, corrosion resistance, and a sleek look that lasts even under high traffic.

1. Understanding Stainless Steel Grades

When choosing custom stainless steel elevator entrances for hotels, office towers, or residential complexes, the grade of stainless steel you select has a direct impact on durability, aesthetics, and cost. Architects often look at 304, 316, and 430 grades because each one serves a different purpose depending on location and traffic volume. In a luxury hotel lobby in Singapore, for example, designers opted for 316-grade doors because the property is close to the sea, where salt exposure would quickly damage a lower grade.

1.1 Common Grades for Elevator Doors (304, 316, 430)

-

304 Stainless Steel is by far the most common choice. It offers a balance of corrosion resistance, workability, and cost. Most high-traffic office buildings rely on 304-grade elevator doors because it can handle fingerprints and frequent cleaning without wearing down the finish.

-

316 Stainless Steel is the premium option, known for its high molybdenum content, which makes it resistant to chloride and salt exposure. Coastal hotels or resorts often specify 316-grade elevator panels to ensure the doors maintain their polished look for decades.

-

430 Stainless Steel is a ferritic grade and much more budget-friendly. It is often used in interior applications where humidity is controlled and corrosion exposure is minimal. For instance, some budget hotel chains use 430-grade panels in service elevators where cost matters more than long-term aesthetics.

| Grade | Key Properties | Typical Hotel Applications | Cost Level |

|---|---|---|---|

| 304 | Strong corrosion resistance, easy to maintain | Guest-facing elevators in lobbies and hallways | $$ |

| 316 | Excellent salt/chloride resistance, premium durability | Coastal resorts, seaside hotels, luxury spaces | $$$ |

| 430 | Budget-friendly, less corrosion resistance | Service elevators, back-of-house hotel use | $ |

1.2 Corrosion Resistance and Durability

The environment plays a huge role in deciding which grade fits best. In high-humidity or coastal areas, even daily cleaning may not prevent rust on 430-grade steel. On the other hand, 316-grade doors can withstand years of oceanfront exposure without showing pits or discoloration. One resort in Miami had previously used 304-grade doors in their beachfront wing but had to replace them after 8 years due to visible corrosion; switching to 316 solved the issue permanently.

In indoor hotel settings with controlled air conditioning, 304 performs exceptionally well. For elevators hidden in service corridors, where aesthetics matter less, 430 remains a practical and cost-effective choice.

1.3 Cost Implications of Each Grade

Price is always part of the equation. Stainless steel sheets used for elevator fabrication can vary significantly in cost depending on grade. While 316 can cost 20–30% more than 304, it often proves cheaper in the long run by reducing maintenance and replacement needs.

Here’s a practical example:

-

A hotel installs 430-grade panels in all guest elevators to save upfront costs.

-

Within 5 years, visible corrosion and dents appear, forcing them to replace panels prematurely.

-

If the same project had used 304 or 316 from the beginning, the lifecycle cost would have been much lower.

Hotels focused on brand image often see stainless steel doors as a one-time investment. By choosing the right grade upfront, they avoid downtime, guest complaints, and expensive replacements.

2. Design and Aesthetic Options

When selecting custom stainless steel elevator doors for hotels or office towers, design is just as critical as durability. Guests often interact with elevators multiple times a day, which makes their appearance a defining feature of the building’s style. Architects typically look beyond just functionality; they want finishes, patterns, and coatings that complement the overall interior concept.

2.1 Finishes: Polished, Brushed, and PVD Coating

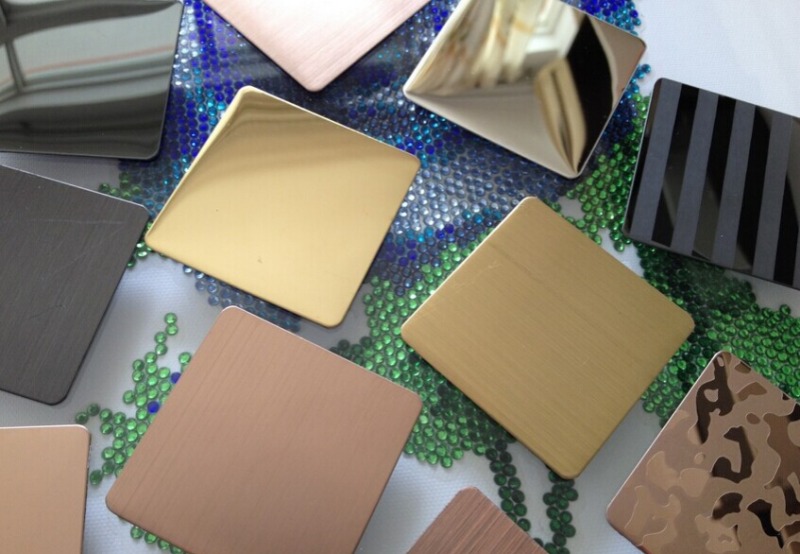

Polished stainless finishes create a mirror-like surface that amplifies light, perfect for luxury hotel lobbies with chandeliers and glass walls. Brushed finishes, on the other hand, minimize fingerprints and are ideal for high-traffic office spaces. In a Dubai financial tower, brushed elevator doors were installed to balance sophistication with daily usability.

For properties seeking standout aesthetics, PVD coatings expand color options far beyond silver. Gold, bronze, or even black titanium finishes are frequently used in boutique hotels to add a signature look without sacrificing durability.

| Finish Type | Visual Effect | Best Application | Maintenance |

|---|---|---|---|

| Polished | High reflection, mirror-like | Luxury hotels, premium residential towers | Needs frequent cleaning |

| Brushed | Matte, subtle grain lines | High-traffic offices, airports | Fingerprint-resistant |

| PVD Coating | Wide color range, luxury tones | Boutique hotels, modern retail complexes | Durable, low upkeep |

2.2 Patterns and Etching for Decorative Appeal

Patterns can completely transform stainless steel surfaces. Geometric etching, wave textures, or even custom hotel logos can be applied directly onto stainless panels. In a Shanghai boutique hotel, the elevator doors featured etched bamboo motifs to tie in with the property’s Asian-inspired design, giving guests an immediate sense of place.

This approach turns the elevator door into a decorative focal point rather than just a functional entrance. Etched or patterned panels are also popular in corporate headquarters, where branding needs to be visible in subtle but sophisticated ways.

2.3 Matching with Interior Themes in Hotels and Offices

Elevator doors don’t stand alone—they must integrate seamlessly with flooring, wall panels, and lighting. For example, in a five-star hotel in Paris, golden PVD-coated doors were paired with marble floors and crystal lighting to maintain a cohesive luxury theme. Meanwhile, a New York office tower combined brushed stainless doors with concrete walls and dark wood trims, creating a modern but professional atmosphere.

In both cases, the choice of finish and design directly supported the overall identity of the building. Even when using standard stainless steel sheets as the base material, thoughtful finishing can elevate the look to match high-end interiors.

3. Size, Structure, and Compatibility

Selecting the proper size and structural specifications for stainless steel elevator doors is crucial in hotels and commercial buildings. Doors that are too heavy, too thin, or incompatible with the existing mechanism can compromise both operation and safety. Architects and engineers usually weigh three key factors: dimensions, thickness/weight, and compatibility with elevator frames and mechanisms.

3.1 Standard vs Custom Dimensions

Most elevators use standard door widths ranging from 800mm to 1200mm, with heights between 2000mm and 2500mm. These standard sizes suit typical passenger elevators, but high-end hotels or modern office towers often prefer custom dimensions to create a more spacious or luxurious feel. For example, a boutique hotel in London opted for custom 1400mm-wide brushed stainless elevator doors to make the lobby appear more open and welcoming.

Custom sizing involves careful measurement of the elevator shaft and interior. A miscalculation of just 5mm can lead to operational issues such as scraping or misalignment, so professional measurement and fabrication are essential.

3.2 Thickness and Weight Considerations

Door thickness affects durability, sound insulation, and ease of movement. Thin doors (1.0–1.2mm) are lighter and easier to operate but may dent more easily. Thicker panels (1.5–2.0mm) provide a premium feel and improved durability but require stronger motors and guides.

| Thickness | Weight per Panel | Typical Application | Pros | Cons |

|---|---|---|---|---|

| 1.0–1.2mm | 35–45kg | Standard office elevators | Lighter, easier to install | Less impact resistance |

| 1.5–1.8mm | 50–60kg | Hotel or high-traffic elevators | Strong, premium feel | Requires stronger mechanism |

| 2.0mm+ | 65–80kg | Luxury hotels, resorts | Highly durable, sound-insulating | Higher installation cost |

For example, in a 5-star hotel in Dubai, 1.8mm thick brushed stainless doors were installed to handle high guest traffic while maintaining a smooth, quiet operation.

3.3 Compatibility with Door Mechanisms and Frames

Compatibility with the elevator’s existing mechanism and frame is non-negotiable. Even the most beautifully finished stainless panels fail if they don’t align perfectly with the guides, rollers, and motor drive.

When retrofitting older elevators, engineers must check:

-

Shaft width and height to ensure proper clearance.

-

Guide rail alignment for smooth sliding of the doors.

-

Motor capacity to handle door weight.

-

Locking and sensor systems for safety compliance.

In a New York office tower renovation, custom elevator panels were fabricated to match the exact width and height of legacy elevator shafts. This precision ensured the doors opened silently and aligned perfectly every time, enhancing both safety and aesthetic appeal.

4. Installation and Technical Requirements

Proper installation of stainless steel elevator doors is critical to ensure smooth operation, longevity, and guest satisfaction in hotels and commercial buildings. Incorrect installation can lead to misalignment, excessive noise, or even operational failures. Key aspects include shaft preparation, precise alignment, and features for noise reduction and smooth operation.

4.1 Preparing Elevator Shafts and Frames

Before installing elevator doors, shafts and frames must be carefully inspected and prepared. Uneven walls, warped frames, or debris can prevent the doors from closing properly.

Key preparation steps include:

-

Measuring the shaft width, height, and depth to ensure the doors will fit precisely.

-

Checking the vertical and horizontal alignment of guide rails.

-

Reinforcing frames if necessary to support heavier stainless steel panels, especially those thicker than 1.5mm.

-

Cleaning the shaft and frame areas to prevent dirt or debris from affecting the installation.

In a recently renovated hotel in Singapore, technicians reinforced older shafts before installing brushed stainless elevator doors, ensuring the panels operated silently and stayed perfectly aligned even under heavy guest traffic.

4.2 Alignment and Fitting Procedures

Accurate alignment is essential for smooth operation and long-term durability. Misaligned doors can scrape, cause wear, or stress the motor mechanism.

Typical installation procedure:

-

Place the stainless steel elevator door panel into the guide rails.

-

Adjust the horizontal and vertical alignment using precision leveling tools.

-

Ensure the top and bottom rollers glide smoothly without friction.

-

Test multiple opening and closing cycles to check for gaps, scraping, or uneven movement.

-

Secure locks, sensors, and frame attachments once perfect alignment is achieved.

| Step | Action | Purpose |

|---|---|---|

| 1 | Position panel in guide rails | Initial fit |

| 2 | Adjust vertical/horizontal alignment | Ensure smooth movement |

| 3 | Test cycles | Detect misalignment or scraping |

| 4 | Secure attachments and sensors | Finalize installation |

A boutique hotel in New York required custom-made stainless lift doors, and technicians spent two days adjusting the alignment carefully to guarantee whisper-quiet operation and zero panel vibration.

4.3 Noise Reduction and Smooth Operation Features

High-traffic areas, such as hotel lobbies, demand elevator doors that operate quietly and reliably. Several design and technical measures improve noise reduction:

-

Using high-quality rollers and precision guide rails to minimize friction.

-

Installing soft-close mechanisms or dampers to prevent slamming.

-

Ensuring panels are properly balanced and weighted according to door thickness.

-

Lubricating moving parts with long-lasting, non-staining lubricants suitable for stainless surfaces.

In a Dubai luxury resort, premium brushed elevator door panels were fitted with dampers and precision rollers. Even during peak check-in hours, the doors operated silently, giving guests a high-end, smooth experience that matched the interior design.

Selection criteria ready? Compare grades, finishes and prices in our stainless steel elevator doors catalog and get an instant quote.