Inox and stainless steel both serve as durable solutions for construction projects, but their selection depends on the intended environment and structural demands. In real projects, engineers prioritize corrosion resistance, load-bearing capacity, and maintenance predictability to determine which variant best meets performance and aesthetic goals, ensuring that each installation aligns with design and safety expectations.

1. How “Inox” and Stainless Steel Are Defined in Construction

In real construction projects, the way materials are named directly affects procurement accuracy, drawing interpretation, and on-site coordination. On mixed international projects, teams often assume “Inox” and stainless steel are interchangeable, but their usage context matters. This section clarifies how both terms function in architectural specifications, structural drawings, and cross-border construction workflows—based on how engineers, contractors, and buyers actually use them on site.

1.1 What “Inox” Means in Architectural and Structural Specifications

On architectural drawings and tender documents for European or Middle East projects, designers frequently specify finishes as “Inox panels” or “Inox cladding”. In design meetings, architects use “Inox” as a material family label, not a grade. It signals corrosion resistance, clean appearance, and suitability for visible applications such as façades, elevator surrounds, or interior wall panels.

When procurement teams translate these specs into a materials list (BOM), they usually convert “Inox” into a specific stainless steel grade and form, often flat products such as architectural-grade stainless steel sheets. The critical point is that “Inox” never defines thickness, alloy composition, or tolerance on its own, so engineers must clarify grade (for example, AISI 304 or 316) before placing orders. On real job sites, skipping this clarification often leads to RFIs and delayed approvals.

1.2 How Stainless Steel Grades Are Commonly Referenced on Construction Drawings

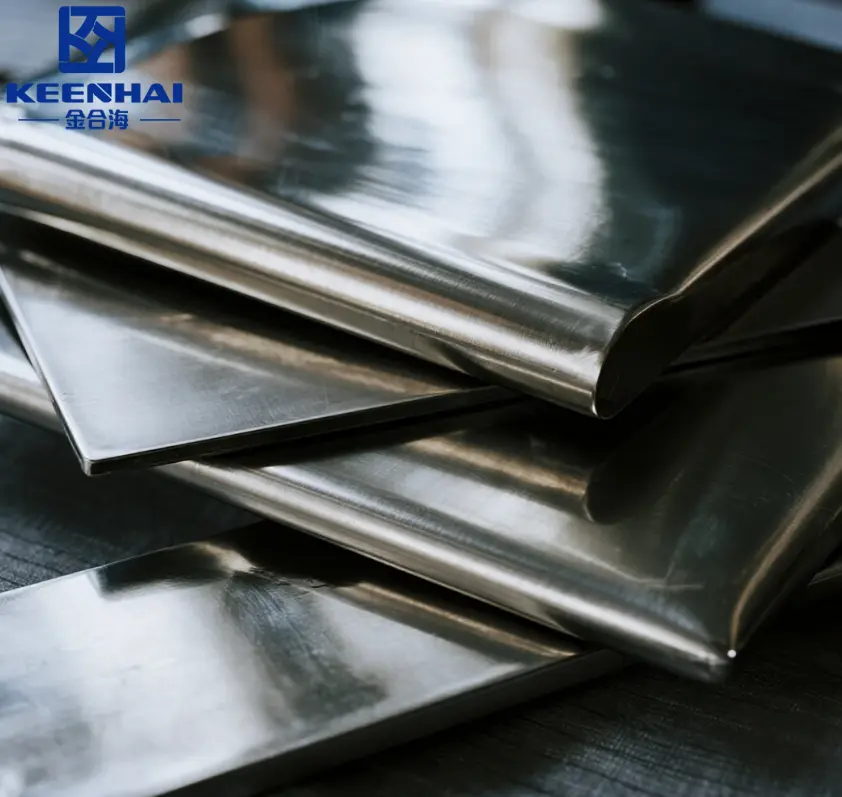

On construction drawings issued for execution, engineers rarely rely on generic terms. Instead, they specify exact standards, grades, and product forms. When contractors review shop drawings, they look for notations such as AISI 304, EN 1.4301, ASTM A240, along with dimensions and surface finish. These details determine whether the material comes as a plate, coil, or cut-to-size component.

In fabrication planning meetings, teams align these notes with sourcing options like stainless steel metal plates or precision-cut sheets to match load, welding, and installation requirements. Clear grade references reduce substitution risk, especially when multiple suppliers bid on the same scope. On large sites, foremen often cross-check drawing callouts against delivery labels to ensure the correct stainless steel arrives before installation begins.

1.3 Why the Two Terms Are Often Used Interchangeably in Global Projects

When contractors from different regions collaborate, terminology naturally blends. On international airport or commercial tower projects, European consultants may write “Inox” in concept documents, while local engineers later convert it to stainless steel grades in IFC drawings. During coordination meetings, both sides often refer to the same material using different names, assuming shared understanding.

Problems arise when the project moves from concept to procurement. Buyers must translate language into specifications that suppliers can price and deliver. The table below reflects how the two terms function differently in practice:

| Term Usage Context | “Inox” in Projects | Stainless Steel in Projects |

|---|---|---|

| Typical appearance | Concept designs, finish notes | Detailed drawings, BOMs |

| Level of precision | Descriptive, non-technical | Grade-, standard-, and form-specific |

| Used by | Architects, designers | Engineers, procurement teams |

| Procurement impact | Requires clarification | Ready for pricing and fabrication |

Successful project teams treat “Inox” as a visual or design cue and stainless steel as the executable material definition. Aligning both early—during drawing reviews and material approval stages—prevents costly mismatches once fabrication and installation begin.

2. Performance Requirements in Construction Environments

On real construction sites, material selection rarely stops at naming conventions. Performance under actual environmental stress determines whether a project runs smoothly or turns into a long-term liability. During engineering coordination meetings and drawing reviews, teams focus on corrosion exposure, structural loads, and fire behavior because these factors directly affect approval timelines, maintenance budgets, and insurance requirements. In this context, both Inox and stainless steel must meet measurable performance benchmarks, not just aesthetic expectations.

2.1 Corrosion Resistance in Exterior and High-Humidity Applications

On coastal job sites, underground parking structures, or indoor pools, corrosion resistance becomes the first checkpoint during material approval. When contractors review exterior façade drawings, they often flag areas exposed to salt spray, acid rain, or constant condensation. In these zones, designers typically expect stainless steel with higher molybdenum content rather than relying on a generic “Inox” label.

During procurement discussions, buyers compare grades based on pitting resistance equivalent number (PREN) and real exposure history. If the material cannot maintain surface integrity after years of humidity and pollutants, replacement costs quickly exceed the initial savings. On site, supervisors also check surface finish consistency, because uneven polishing accelerates localized corrosion, especially around fasteners and welded joints.

2.2 Structural Strength and Load-Bearing Considerations

On construction drawings for canopies, handrails, curtain wall supports, or decorative load-sharing elements, engineers specify minimum yield strength and thickness rather than relying on material names. In project meetings, structural teams often ask one practical question: Can this stainless steel section handle both dead load and dynamic forces such as wind or crowd movement?

When contractors prepare shop drawings, they typically follow a clear process:

-

Match specified grade to required yield and tensile strength.

-

Confirm thickness tolerance based on span and fixing method.

-

Verify connection details, especially bolt shear and weld zones.

Stainless steel delivers predictable mechanical behavior only when grade and form align with the load model. On-site inspections frequently fail components that look correct visually but miss required strength margins on paper.

2.3 Fire Resistance and Behavior Under High Temperatures

During fire strategy reviews and authority submissions, stainless steel often appears in escape routes, façade systems, and service enclosures. Unlike coated carbon steel, it does not emit toxic fumes when exposed to high temperatures, which makes it attractive for enclosed public spaces. However, engineers still evaluate how strength drops as temperature rises.

On high-rise projects, fire consultants examine whether stainless steel elements maintain integrity long enough to meet evacuation timelines. At elevated temperatures, stainless steel retains structural stability better than many alternatives, but designers still account for expansion, joint movement, and fixing deformation. On site, installation teams follow strict sequencing to avoid heat distortion during welding, ensuring fire-performance assumptions remain valid in real conditions.

3. Material Selection Based on Construction Use Cases

When contractors review the full scope of a construction project, they quickly realize that not all stainless steel or Inox grades perform equally across different applications. Material choice depends heavily on location, load requirements, and aesthetic goals, and decisions are often finalized during procurement and engineering coordination meetings. Selecting the right type early prevents costly on-site adjustments and ensures compliance with design intent.

3.1 Exterior Facades, Curtain Walls, and Cladding Systems

On modern high-rise buildings, exterior facades and curtain walls face wind, rain, UV exposure, and pollution. Engineers and designers prefer stainless steel sheets with high corrosion resistance and uniform surface finish. For instance, using a stainless steel sheet with the correct grade ensures that panels maintain visual quality over decades, even in coastal environments.

Installation teams follow these steps:

-

Verify panel dimensions against shop drawings.

-

Confirm fixing systems and tolerances for thermal expansion.

-

Check surface orientation and alignment on façade support brackets.

Accurate material selection reduces maintenance frequency and prevents premature discoloration or rusting, which is critical for landmark architectural projects.

3.2 Interior Structural Elements, Columns, and Framing

Inside office buildings, shopping malls, or public facilities, stainless steel is often used for columns, beams, and framing elements that require both strength and visual appeal. On construction drawings, engineers specify grades that meet both tensile strength and fire-resistance requirements, ensuring the elements carry live and dead loads safely.

Contractors typically follow a workflow:

-

Cross-check material grade with structural load tables.

-

Confirm cut lengths and bending tolerances.

-

Install supports in sequence to align with flooring and ceiling elements.

Choosing reliable stainless steel products guarantees predictable mechanical performance, making large-scale interior installations safer and more durable.

3.3 Decorative and Functional Architectural Components

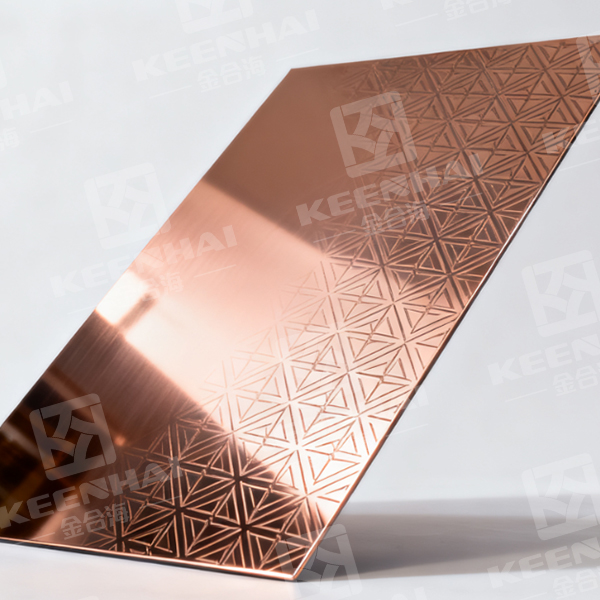

From handrails and staircases to custom elevator doors, architectural details demand precision and consistent finish. Designers often select a combination of polished, brushed, or patterned stainless steel surfaces, sometimes specifying stainless steel metal plates for custom fabrication.

Installation workflow includes:

-

Review component placement on interior and exterior drawings.

-

Confirm welding or fixing methods without compromising finish.

-

Inspect alignment, joints, and surface treatment before final approval.

By focusing on both functionality and aesthetics, teams ensure that decorative components complement structural elements while maintaining longevity under daily use.

4. Cost, Availability, and Specification Control

For large-scale construction projects, budgeting and reliable material supply are as critical as performance. Project managers consistently note that minor deviations in grade or finish can ripple into major schedule delays and unexpected costs. By coordinating early with suppliers, teams can secure bulk orders at predictable prices and ensure that the materials specified on drawings match actual deliveries.

4.1 Initial Material Cost and Budget Predictability

On procurement sheets, initial pricing for stainless steel products can vary by grade, thickness, and surface finish. For instance, choosing a higher-grade stainless steel sheet for exterior cladding may increase upfront costs by 15–25%, but this investment often reduces lifecycle maintenance and replacement expenses.

Typical workflow for cost control:

-

Compare unit prices across multiple certified suppliers.

-

Verify that chosen grades meet both structural and aesthetic requirements.

-

Allocate contingency funds for surface treatment or custom cutting.

Maintaining transparent cost tracking ensures budget adherence while avoiding material substitutions that compromise design integrity.

4.2 Availability of Standard Grades, Sizes, and Finishes

In real projects, teams frequently encounter supply bottlenecks when non-standard sizes or rare finishes are specified. Contractors and procurement managers prioritize readily available grades and dimensions, because any delay directly affects installation timelines. By sourcing from established suppliers, such as those offering մետաղական չժանգոտվող պողպատե թերթեր, projects maintain continuity and reduce scheduling risks.

Steps to confirm availability:

-

Verify stock levels with multiple authorized distributors.

-

Cross-check supplier lead times against project schedule milestones.

-

Reserve high-demand items in advance to prevent on-site shortages.

Early verification of standard materials secures workflow efficiency and minimizes last-minute procurement crises.

4.3 Impact of Supply Consistency on Large-Scale Construction Schedules

Construction timelines are highly sensitive to the consistency of material delivery. Even minor grade mismatches or batch variations can force re-fabrication or on-site adjustments, adding labor hours and delaying milestone completion. Coordination between procurement, engineering, and fabrication teams ensures:

-

Confirmation of batch uniformity and certifications.

-

Scheduling deliveries to align with installation sequences.

-

Continuous monitoring of logistics to preempt delays.

Consistent supply enables contractors to adhere strictly to the planned schedule, ensuring cost efficiency and timely project completion.

5. Fabrication, Installation, and Long-Term Maintenance

For large-scale projects, fabrication and installation precision often determine the final structural integrity and aesthetic outcome. Contractors emphasize that even premium materials can underperform if cutting, welding, or assembly steps are mismanaged. Teams on-site rely heavily on detailed engineering drawings and pre-fabrication checks to ensure components fit seamlessly and meet design tolerances.

5.1 Welding, Cutting, and On-Site Fabrication Efficiency

On construction sites, efficient handling of stainless steel panels, plates, and sheets is crucial. Fabricators typically follow a stepwise process:

-

Inspect and verify material specifications against the BOM.

-

Cut and shape components using CNC or laser cutting for precise dimensions.

-

Apply welding techniques according to design requirements, ensuring structural strength without compromising corrosion resistance.

When contractors work with high-quality stainless steel sheets or similar materials, they often achieve faster assembly times while maintaining visual and structural consistency, which directly impacts project profitability and schedule adherence.

5.2 Installation Tolerances and Construction Accuracy

Accurate installation is non-negotiable for curtain walls, façade panels, and interior structural frames. Installation teams use laser alignment tools and jigs to verify that panels meet specified tolerances, often within ±1 mm for visible surfaces. Steps include:

-

Positioning prefabricated panels according to site layout plans.

-

Securing temporary supports and adjusting alignment continuously.

-

Final bolting or welding while confirming plumb, level, and square dimensions.

Maintaining strict tolerances ensures long-term performance and prevents gaps, deformation, or misalignment that could compromise durability or aesthetics.

5.3 Maintenance Requirements Over the Building Lifecycle

In real projects, maintenance planning starts at the procurement stage. Stainless steel products generally require low upkeep, but routine cleaning, inspection, and occasional surface refinishing extend service life. Contractors often schedule:

-

Quarterly visual inspections for corrosion or scratches.

-

Cleaning using mild detergents to remove environmental residues.

-

Corrective actions for damaged coatings or weld seams.

When long-lasting stainless steel products from reputable suppliers are used, facility managers benefit from predictable maintenance intervals, minimizing downtime and lifecycle costs.

For construction projects, stainless steel is generally the better choice over Inox due to its proven corrosion resistance, predictable structural performance, and wide availability of standardized grades. Teams working on exterior facades, structural elements, or high-humidity environments consistently rely on stainless steel sheets and plates because they deliver long-term durability, precise fabrication outcomes, and lower maintenance requirements. Using stainless steel ensures that both engineering and aesthetic expectations are met without compromise.