1. Understanding Material Differences

When selecting materials for custom projects, understanding the fundamental differences between Inox and stainless steel is essential. These materials may seem similar at first glance, but their alloy composition, surface treatment, and mechanical properties can significantly impact project performance, aesthetics, and longevity. Choosing the right material from the outset prevents costly mistakes during fabrication and installation.

1.1 Composition and Alloy Variations

Տերմինը Ինոքս generally refers to high-quality stainless steel grades with enhanced corrosion resistance, typically 304 or 316 alloys. Stainless steel, in contrast, is a broader category that includes a variety of grades with differing chromium, nickel, and molybdenum content. The alloy composition determines how the material responds to outdoor environments, chemical exposure, and fabrication processes.

For example:

-

304 Inox contains about 18% chromium and 8% nickel, offering excellent corrosion resistance for interior applications and moderate outdoor exposure.

-

316 Stainless Steel includes 2-3% molybdenum, which significantly improves resistance against chloride-induced corrosion, making it ideal for coastal architecture or swimming pool installations.

-

Lower-grade stainless steels may perform well in dry indoor conditions but can suffer pitting or staining when exposed to harsh weather.

In practical scenarios, a custom Չժանգոտվող պողպատից թերթ used in a modern kitchen island must resist repeated cleaning with acidic detergents. Meanwhile, 316 Inox is often chosen for decorative outdoor railings or marine-grade architectural panels, where durability against salty air is critical.

1.2 Surface Finishes and Corrosion Resistance

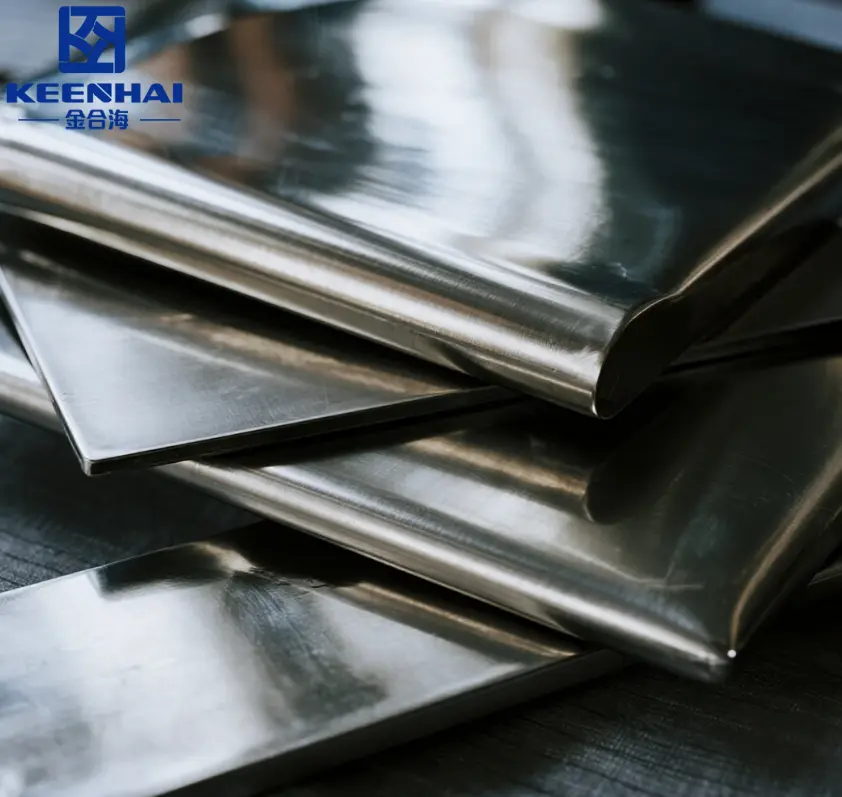

Surface treatment plays a huge role in both appearance and longevity. Polished, brushed, or bead-blasted finishes not only affect aesthetics but also directly influence how a metal surface interacts with moisture and environmental contaminants.

-

Brushed or satin finishes hide fingerprints and minor scratches, making them perfect for high-traffic interior panels.

-

Mirror-polished finishes provide a striking visual impact but require regular maintenance to prevent water spots and corrosion streaks.

-

Electropolishing, often applied to Inox, removes micro-roughness and enhances corrosion resistance, which is essential for high-humidity environments.

Corrosion resistance comparison table:

| Material / Grade | Chromium % | Nickel % | Molybdenum % | Typical Use Case | Corrosion Resistance |

|---|---|---|---|---|---|

| 304 Inox | 18 | 8 | 0 | Interior decorative panels, furniture | Բարձր |

| 316 Stainless Steel | 16-18 | 10-14 | 2-3 | Coastal railings, outdoor kitchens | Very High |

| Standard Stainless Steel | 10-12 | 0-8 | 0 | Dry interior applications | Moderate |

In real-world construction, architects often select 316 stainless steel panels for high-humidity areas like rooftop terraces or spa facades, while Մետաղ չժանգոտվող պողպատից թերթ finishes are chosen for indoor partitions where aesthetic consistency is key. Understanding these surface options upfront avoids costly repainting or replacement later.

1.3 Strength and Durability Comparisons

Mechanical properties are another critical factor. While both Inox and stainless steel are strong, the yield strength, tensile strength, and hardness vary depending on the grade and processing method.

-

304 Inox typically has a tensile strength of 520 MPa, sufficient for light to medium structural components like decorative stair railings or furniture frames.

-

316 Stainless Steel provides slightly higher tensile strength (~580 MPa) and superior resistance to stress corrosion cracking, making it reliable for exposed outdoor installations.

-

Work-hardened stainless steel sheets, such as Stainless Steel Metal Plate, offer additional rigidity for load-bearing partitions or elevator doors.

In a practical construction scenario, imagine fabricating a custom balcony railing. Step-by-step:

-

Select the grade: 316 Inox for coastal resistance.

-

Determine thickness: Minimum 2mm for structural safety.

-

Choose surface finish: Satin brushed to hide minor scratches and fingerprints.

-

Fabrication: Cut, bend, and weld using TIG techniques for minimal oxidation marks.

-

Տեղադրում: Secure panels with stainless steel fasteners and check for corrosion-prone contact points.

By carefully matching composition, surface treatment, and strength to the project environment, you ensure both durability and aesthetic excellence.

2. Performance in Custom Projects

Custom projects demand materials that perform reliably under both structural and aesthetic pressures. Understanding how Inox and stainless steel behave in real-world applications ensures your installations remain durable, visually appealing, and low-maintenance over time.

2.1 Structural Applications

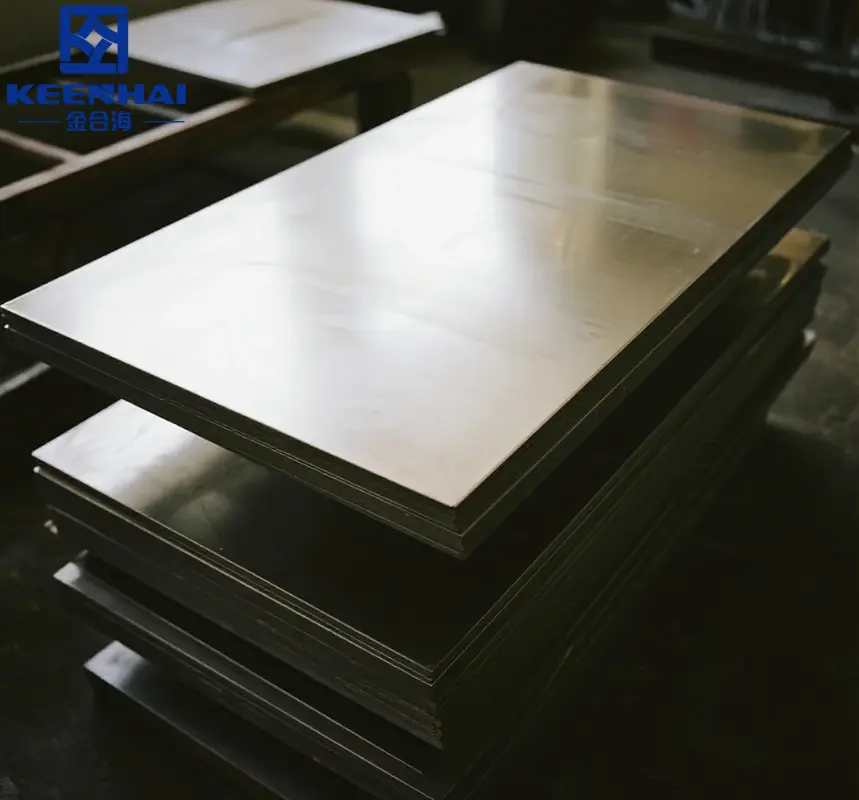

When it comes to structural use, the choice of material directly impacts safety, stability, and lifespan. High-quality stainless steel sheets offer excellent load-bearing capabilities while resisting environmental stresses like moisture, UV exposure, and temperature fluctuations.

For example, in a modern high-rise balcony railing project:

-

Select the right grade: 316 stainless steel panels resist stress corrosion in coastal or high-humidity areas.

-

Determine thickness: Engineers often specify 2–5 mm, balancing rigidity with weight.

-

Cutting and bending: Use CNC shearing and press brakes to maintain precise tolerances.

-

Welding and joining: TIG welding ensures minimal oxidation marks, preserving both strength and surface integrity.

-

Structural testing: Load tests simulate wind and human weight to confirm compliance with safety standards.

Stainless steel panels outperform lower-grade metals because their combination of chromium, nickel, and sometimes molybdenum prevents micro-cracks and maintains tensile strength even under heavy loads. In large outdoor staircases or pedestrian bridges, this reliability is critical.

2.2 Decorative and Architectural Uses

Beyond raw strength, aesthetics drive material choice in custom architecture. Inox and premium stainless steel sheets provide consistent finishes and precise surface textures that enhance both interior and exterior designs. Brushed or mirror-polished surfaces reflect light differently, creating dynamic visual effects in spaces like hotel lobbies, museums, or luxury retail facades.

-

Facade panels: Using Չժանգոտվող պողպատից մետաղական ափսե with brushed finishes ensures uniform color and minimal fingerprints on large exterior surfaces.

-

Interior accents: Polished sheets can be applied to elevator doors, decorative wall cladding, or kitchen backdrops.

-

Customization options: Architects can choose laser-cut patterns, perforations, or embossed textures without compromising structural integrity.

In a real project, installing a custom elevator lobby wall involves:

-

Selecting a high-grade metal sheet that balances aesthetics and durability.

-

Designing cutouts or patterns using CAD software for precise alignment.

-

Pre-polishing each panel before site delivery to minimize on-site finishing.

-

Securing panels with concealed fasteners to maintain a seamless look.

By combining material strength with finish consistency, these applications achieve both visual impact and long-term resilience.

2.3 Maintenance and Longevity Considerations

Longevity depends on proactive maintenance and understanding environmental factors. High-quality stainless steel sheets and Inox resist corrosion, but performance varies with exposure and finish. Coastal buildings, rooftop terraces, or humid interiors benefit from grades like 316, which withstand chloride-induced corrosion and maintain surface luster for decades.

Maintenance steps for long-term performance:

-

Routine cleaning: Wipe down surfaces weekly with non-abrasive detergents to remove dust and contaminants.

-

Check fasteners and joints: Inspect bolts and welds quarterly for signs of stress or discoloration.

-

Surface restoration: Lightly polish brushed finishes every 6–12 months to restore sheen and remove minor scratches.

-

Environmental adjustments: Avoid direct contact with dissimilar metals that may accelerate galvanic corrosion.

In large-scale installations, such as outdoor canopies or hotel balconies, following these steps ensures decades of maintenance-free use, while maintaining the architectural vision intact.

3. Cost and Procurement Factors

Understanding the costs associated with Inox and stainless steel is crucial for any custom project. Beyond just material prices, procurement involves evaluating fabrication, machining, and lead times to avoid budget overruns and scheduling delays. In-depth cost analysis ensures smarter purchasing decisions and smoother project execution.

3.1 Material Pricing Differences

Material cost is the first variable to assess. High-quality stainless steel sheets generally cost more than lower-grade stainless steel due to higher alloy content, enhanced corrosion resistance, and tighter manufacturing tolerances. For instance:

-

304 stainless steel panels are widely used and moderately priced, suitable for interior or semi-exposed applications.

-

316 Inox commands a premium due to superior chloride and chemical resistance, often required for coastal or industrial settings.

-

Specialty finishes like electropolished or patterned surfaces further increase costs, sometimes by 15–30% per square meter.

Price comparison table (indicative for standard sheet sizes 1.2m × 2.4m, 2mm thickness):

| Material Type | Approx. Cost per Sheet (USD) | Typical Use Case | Notes |

|---|---|---|---|

| 304 Stainless Steel Panel | 150–180 | Interior cladding, furniture | Moderate corrosion resistance |

| 316 Inox | 220–270 | Outdoor railings, coastal facades | High corrosion resistance |

| Brushed / Patterned Finish | +20–50 | Decorative wall panels | Adds visual appeal and scratch resistance |

In procurement planning, it’s essential to align material grade with project environment to avoid overspending on unnecessarily high-spec sheets or compromising durability by under-specifying.

3.2 Fabrication and Machining Costs

Fabrication costs vary depending on complexity, sheet thickness, and required precision. Premium stainless steel sheets are more challenging to cut, bend, and weld compared to standard grades due to hardness and spring-back tendencies. Key cost factors include:

-

Cutting: Laser cutting or CNC shearing ensures clean edges but increases labor and energy costs.

-

Bending and Forming: Thick or high-grade sheets may require multiple press brake passes, adding time and labor.

-

Welding and Finishing: TIG or MIG welding is recommended for high-grade panels, followed by careful polishing to remove oxidation and preserve finish.

-

Custom Patterns or Perforations: Decorative designs increase machining time and inspection requirements, further raising costs.

For example, creating a laser-cut custom staircase railing from premium stainless steel sheets may cost 20–40% more than a simple flat panel, but it ensures precision, longevity, and visual consistency.

3.3 Availability and Lead Times

Lead time affects project scheduling and overall cost. Material availability depends on grade, thickness, and finish:

-

Standard 304 sheets are typically in stock at most suppliers, allowing delivery within 1–2 weeks.

-

316 Inox or custom finishes may require 3–6 weeks, especially if sheets are electropolished, patterned, or perforated.

-

Bulk orders can affect delivery schedules, so coordinating procurement with fabrication timelines is critical.

Steps to manage procurement effectively:

-

Forecast project needs: Quantify total sheet area and required grades in advance.

-

Confirm supplier stock and lead times: Communicate specifications clearly to avoid delays.

-

Factor in fabrication schedules: Include cutting, bending, and welding times in planning.

-

Plan for contingency: Maintain a 5–10% buffer in material orders for unexpected wastage or defects.

By integrating material cost, fabrication complexity, and lead time considerations, you can control budget, avoid delays, and maintain high-quality standards in every custom project.

4. Choosing the Right Material

Selecting the right material for custom projects requires a deep understanding of both technical specifications and project goals. The choice between Inox and stainless steel depends on matching performance properties to real-world conditions, prioritizing aesthetics versus functionality, and working with reliable suppliers who can meet quality and timeline requirements.

4.1 Matching Project Requirements to Material Properties

Every project has unique demands, and material selection must address them directly. Premium stainless steel sheets are excellent for structural and decorative applications where corrosion resistance, tensile strength, and surface finish matter.

In practice, engineers and architects consider:

-

Environmental exposure: For coastal terraces or rooftop installations, 316 Inox resists chloride corrosion, whereas 304 may suffice for indoor panels.

-

Load-bearing requirements: Thicker sheets or metal plates can handle higher static and dynamic loads without bending.

-

Surface aesthetics: Brushed, mirror, or patterned finishes affect visual impact and maintenance requirements.

For instance, a custom restaurant facade using high-quality stainless steel panel involves:

-

Choosing 316 sheets for long-term outdoor durability.

-

Prefabricating panels with CNC cutting for precise dimensions.

-

Electropolishing edges to maintain corrosion resistance and a sleek appearance.

By aligning project needs with material properties, you reduce the risk of over-specification and ensure that every panel contributes to structural and visual goals.

4.2 Decision Criteria: Aesthetic vs Functional Priorities

Sometimes, aesthetic appeal outweighs purely functional concerns, and vice versa. A clear hierarchy of priorities helps in decision-making:

-

Functional-first projects: Rooftop railings, stair treads, and balcony panels demand high-strength, high-resistance Inox or չժանգոտվող պողպատե վահանակներ to meet safety and longevity criteria.

-

Aesthetic-first projects: Elevator interiors, decorative wall panels, and showroom installations prioritize surface finish, reflective quality, or patterning.

Key steps to balance these priorities:

-

List critical functional requirements: Load capacity, corrosion resistance, environmental conditions.

-

Define aesthetic expectations: Surface finish, polish level, and color consistency.

-

Compare available materials: Match the best compromise between function and visual appeal.

-

Prototype if necessary: Small-scale samples reveal how finishes perform under light, touch, and environmental conditions.

For example, in a luxury hotel lobby, electropolished 304 stainless steel panels can offer both structural reliability and a polished, visually striking finish, ensuring long-term performance without compromising aesthetics.

4.3 Supplier Selection Tips

Even the best material can underperform if sourced from unreliable suppliers. Selecting a supplier requires evaluating quality, experience, and delivery capabilities.

-

Verify certifications and material traceability: Ensure sheets are genuine Inox or stainless steel grades.

-

Assess fabrication capabilities: Check for CNC cutting, welding precision, and polishing expertise.

-

Review lead times and stock availability: Confirm suppliers can meet project schedules.

-

Request references or past project examples: Look for evidence of quality control, finish consistency, and long-term durability.

Working with a reputable brand like pvdstainlesssteel can simplify these steps, as they provide certified sheets, precision fabrication, and technical support for both decorative and structural custom projects.

By carefully evaluating material properties, balancing aesthetics and function, and choosing the right supplier, you ensure that every component performs as intended and contributes to a high-quality finished project.

5. Case-Specific Recommendations

Choosing the right material often depends on the specific demands of the project. Here, we provide actionable guidance for high-load structural components, interior decorative panels, and outdoor custom installations, ensuring both performance and aesthetics are optimized.

5.1 High-Load Structural Components

For projects that bear significant weight or endure dynamic loads, material selection is critical. Premium stainless steel sheets such as 316 Inox are ideal for load-bearing applications because they combine high tensile strength with exceptional corrosion resistance.

Real-world examples include:

-

Staircases and handrails: Use 3–5 mm thick sheets for treads and panels to prevent bending under foot traffic.

-

Balcony railings and walkways: 316 Inox panels handle both environmental stress and human load safely.

-

Support frames for decorative cladding: Combine stainless steel sheets with reinforced mounting brackets to maintain rigidity and longevity.

Fabrication steps for high-load applications:

-

Select the correct grade and thickness based on structural calculations.

-

Cut panels using CNC or laser systems for exact tolerances.

-

Weld using TIG methods to maintain both strength and surface integrity.

-

Test structural components for load and stress points before installation.

By following these steps, load-bearing components remain both safe and visually consistent, even in high-traffic or exposed environments.

5.2 Interior and Decorative Panels

Interior projects prioritize appearance, surface quality, and precision fitting. High-quality stainless steel panels provide consistent finishes, reflectivity, and long-term durability while minimizing maintenance needs.

Examples include:

-

Elevator cladding: Polished or patterned stainless steel sheets reduce fingerprints and enhance luxury appeal.

-

Reception desks and wall panels: Brushed finishes hide scratches in high-traffic zones.

-

Custom furniture accents: Electropolished or laser-cut panels add depth and detail.

Installation process for decorative panels:

-

Measure and cut panels precisely to avoid on-site adjustments.

-

Prefinish panels off-site to maintain surface quality.

-

Mount with concealed fasteners or magnetic systems for a seamless look.

-

Perform final alignment checks and polish if necessary to ensure visual uniformity.

For large-scale interior installations, using Stainless Steel Metal Plate allows precise fabrication and easy integration into design plans, providing both aesthetic impact and functional durability. Collaborating with a trusted supplier ensures you receive panels that match design specifications exactly, minimizing rework and installation issues.

5.3 Outdoor Custom Installations

Outdoor projects face demanding conditions: UV exposure, moisture, temperature fluctuations, and chemical contact. 316 Inox or premium stainless steel panels are recommended because they withstand corrosion, maintain structural integrity, and preserve surface quality.

Key applications include:

-

Architectural facades and sunshades: Use thick panels with brushed or matte finishes to reduce glare and resist staining.

-

Pool surrounds and terraces: 316 stainless steel prevents rust from chlorinated water and humidity.

-

Custom outdoor furniture: Panels must resist scratches and maintain finish under heavy use.

Installation steps for outdoor applications:

-

Evaluate environmental exposure and select appropriate grade.

-

Prefabricate panels with accurate cuts and predrilled holes.

-

Use corrosion-resistant fasteners and supports.

-

Inspect and seal joints to prevent water infiltration.

-

Schedule routine inspections and light maintenance annually.

For outdoor installations where durability is non-negotiable, sourcing materials from a reliable partner like pvdstainlesssteel ensures certified sheets and precision fabrication, keeping your project low-maintenance and visually striking for decades.