Understanding Material Inox: Material Inox, or stainless steel, combines chromium, nickel, and iron to deliver excellent corrosion resistance, strength, and durability. It’s widely used in architectural panels, kitchen equipment, and industrial applications. Choosing the right type and grade ensures long-term performance, reduced maintenance, and aesthetic consistency. Premium options like stainless steel sheets offer precise finishes suitable for both commercial and residential projects.

1. Understanding Material Inox

1.1 Definition and Composition of Inox

Material Inox, commonly referred to as stainless steel, is a corrosion-resistant alloy primarily composed of iron, chromium, and nickel. Chromium content typically ranges from 10.5% to 20%, forming a passive oxide layer that protects the metal from rust and stains. Some grades also include molybdenum, manganese, or titanium to enhance strength, corrosion resistance, and durability. Stainless steel sheets are a versatile form of Inox widely used in both structural and decorative applications, from kitchen panels to commercial elevator cladding. Inox offers a unique combination of longevity and aesthetic appeal, making it a premium choice over regular steel in high-exposure environments.

1.2 Key Advantages Over Regular Steel and Aluminum

Material Inox outperforms regular steel and aluminum in several crucial aspects. Corrosion resistance, mechanical strength, және surface finish flexibility make it suitable for applications that demand both durability and visual quality. Aluminum is lightweight but scratches and dents easily, while plain steel may rust quickly without protective coatings.

| Property Comparison | Material Inox | Regular Steel | Aluminum |

|---|---|---|---|

| Коррозияға төзімділік | High (10–20% Cr) | Төмен | Орташа |

| Tensile Strength (MPa) | 520–750 | 400–550 | 200–400 |

| Surface Finish Options | Brushed, Mirror, Etched | Limited | Polished, Anodized |

| Typical Applications | Architectural, Industrial, Appliances | Construction | Automotive, Lightweight Structures |

This table highlights why Inox is often the preferred choice for long-term performance, particularly in areas with moisture, chemicals, or high foot traffic.

1.3 Common Grades and Standards

Inox comes in several widely used grades, each with specific composition and performance characteristics:

- 304 Stainless Steel: 18–20% Cr, 8–10% Ni; excellent corrosion resistance for indoor and mild outdoor applications.

- 316 Stainless Steel: 16–18% Cr, 10–14% Ni, 2–3% Mo; highly resistant to saltwater and chemical exposure, ideal for marine environments.

- 430 Stainless Steel: 16–18% Cr, <0.75% C; ferritic, magnetic, less expensive, best for decorative panels and appliances.

Each grade conforms to international standards (ASTM, ISO) ensuring consistent quality and predictability. High-quality stainless steel panels like these are frequently deployed in commercial kitchens, elevator interiors, and facade cladding due to their strength and low-maintenance requirements.

This foundation on Material Inox naturally leads into mechanical strength, corrosion behavior, and application choices, forming a solid base for buyers to make informed decisions when selecting materials for their projects.

2. Mechanical and Physical Properties

2.1 Tensile Strength, Hardness, and Flexibility

Material Inox exhibits tensile strength ranging from 520 to 750 MPa, depending on the grade, making it significantly stronger than standard carbon steel and aluminum alloys. Its hardness typically measures between 150–200 HB, which provides resistance against scratches and dents in high-traffic environments. Despite its strength, certain austenitic grades maintain excellent flexibility, allowing panels or sheets to bend without cracking, ideal for architectural facades, elevator cladding, and kitchen surfaces. When selecting sheets for installation, consider:

- Thickness and gauge relative to load requirements.

- Expected bending or forming operations.

- Surface treatment compatibility to maintain mechanical integrity.

2.2 Corrosion Resistance in Different Environments

Material Inox is engineered to resist corrosion in diverse conditions. 304 grade excels in standard indoor and mild outdoor settings, while 316 grade resists saltwater, chlorides, and aggressive chemicals. For example, stainless steel sheets in commercial kitchens withstand repeated exposure to cleaning agents and moisture without rusting. Coastal architectural projects often require 316 or higher grades, which maintain structural integrity over decades. The chromium and nickel content forms a passive layer, providing self-healing protection even if the surface is scratched.

2.3 Thermal and Electrical Conductivity Considerations

While Inox is not as thermally or electrically conductive as aluminum or copper, it performs reliably in applications requiring moderate heat transfer and electrical insulation. Thermal conductivity for 304 Inox is approximately 16 W/m·K, lower than aluminum’s 205 W/m·K, making it suitable for controlled heat environments like ovens or decorative panels near heat sources. Electrical resistivity is around 0.72 μΩ·m, sufficient for non-critical grounding or insulation purposes. Designers and engineers often weigh mechanical resilience over conductivity, ensuring that Inox panels deliver longevity while maintaining thermal stability.

3. Types and Finishes of Material Inox

3.1 Austenitic, Ferritic, and Martensitic Inox

Material Inox comes in three main metallurgical types. Austenitic Inox contains high chromium and nickel levels, offering excellent corrosion resistance and non-magnetic properties, making it ideal for kitchen equipment and architectural panels. Ferritic Inox is magnetic, moderately corrosion-resistant, and more cost-effective, often used for decorative facades and automotive trims. Martensitic Inox contains higher carbon, providing superior hardness and wear resistance, suitable for cutting tools and structural components. Choosing the correct type depends on application demands, environmental exposure, and mechanical requirements.

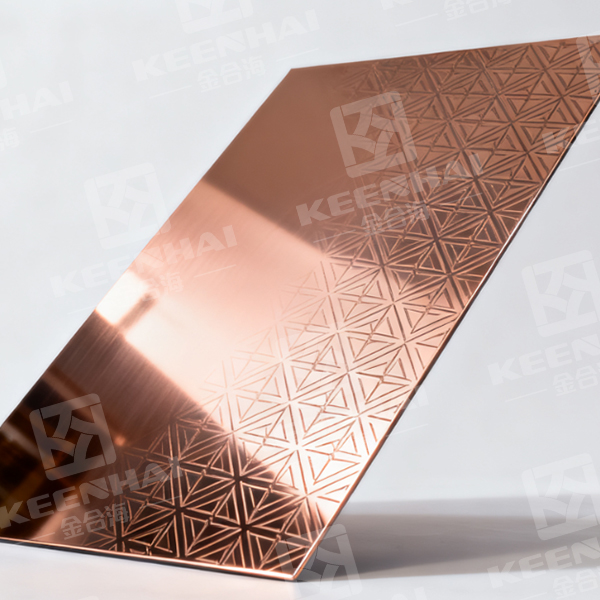

3.2 Surface Finishes: Brushed, Mirror, Etched, and Polished

Surface finish dramatically impacts both aesthetics and performance. Brushed finishes provide a soft, directional texture that hides fingerprints, while mirror finishes create highly reflective, premium surfaces. Etched or patterned finishes enhance visual appeal and add slip-resistance for flooring or stair applications. Polished finishes smooth the metal, improving cleanability in hygienic environments such as hospitals or commercial kitchens. Each finish requires specific care and maintenance to preserve longevity and appearance.

3.3 Choosing the Right Finish for Applications

Selecting the proper finish involves balancing appearance, maintenance, and functional requirements:

- High-touch areas: Brushed or satin finishes reduce visible scratches and fingerprints.

- Visual impact: Mirror or polished finishes elevate architectural appeal.

- Outdoor use: Etched or matte finishes minimize glare and weathering effects.

- Industrial environments: Polished or treated surfaces resist chemical exposure and corrosion.

For premium stainless steel panels, combining the right type with an appropriate finish ensures durable performance and aesthetic consistency across any project.

4. Application-Based Selection

4.1 Architectural and Decorative Projects

Material Inox is widely used in modern architectural and decorative projects due to its combination of strength, corrosion resistance, and visual appeal. Brushed or mirror-finished sheets create sleek elevator panels, lobby cladding, and façade elements. Designers often select austenitic grades for high-moisture or coastal environments to ensure long-lasting rust-free surfaces. For instance, large-scale hotels frequently use stainless steel sheets to achieve seamless reflective surfaces that maintain elegance under constant foot traffic.

4.2 Industrial and Structural Uses

In industrial settings, martensitic or ferritic Inox provides the durability needed for machinery, piping, and structural frameworks. Its high tensile strength and wear resistance ensure reliable performance in factories or chemical plants. Step-by-step selection typically involves:

- Determining load-bearing or mechanical stress requirements.

- Assessing exposure to chemicals, moisture, or extreme temperatures.

- Selecting the appropriate grade and thickness to balance cost and longevity.

4.3 Kitchen, Appliances, and Furniture

Material Inox is a top choice for commercial kitchens, appliances, and premium furniture. Its resistance to stains, heat, and cleaning agents keeps surfaces hygienic and visually appealing. For high-end cabinetry, countertops, or restaurant equipment, stainless steel sheets allow easy fabrication, precise shaping, and long-term durability. Designers often combine aesthetic finishes with corrosion-resistant grades to ensure both style and functionality in everyday use.

5. Cost, Maintenance, and Longevity

5.1 Price Comparison with Aluminum and Steel

Material Inox is generally more expensive than aluminum but often comparable or slightly higher than standard carbon steel, depending on the grade. Its higher initial cost is offset by long-term benefits such as reduced replacement frequency, superior corrosion resistance, and minimal maintenance needs. For example, Grade 304 stainless steel sheets cost roughly $2.5–$4 per kg, while aluminum is around $2 per kg. Choosing Inox becomes cost-effective when factoring in lifetime performance in harsh or high-moisture environments.

5.2 Maintenance Needs and Surface Treatments

Material Inox requires minimal maintenance compared to aluminum or untreated steel. Regular cleaning with mild detergents prevents surface deposits and preserves the finish. Optional treatments include passivation, electropolishing, or coating to enhance corrosion resistance and maintain mirror or brushed surfaces. Key maintenance steps include:

- Wiping down with non-abrasive cloths weekly or after heavy use.

- Applying protective oils or coatings if exposed to saltwater or chemicals.

- Checking for scratches or dents and repairing promptly to preserve the passive layer.

5.3 Expected Lifespan in Different Conditions

The lifespan of Material Inox depends on the grade, environment, and finish. In indoor, low-humidity conditions, 304 grade can last 50+ years with proper care. For coastal or chemically aggressive environments, 316 grade can exceed 40 years without rusting. Its corrosion resistance, mechanical strength, and flexibility ensure that both structural and decorative applications maintain functionality and appearance over decades, making it a premium investment for long-term projects.

In conclusion, investing in high-quality Material Inox ensures projects combine strength, corrosion resistance, and aesthetic appeal. Whether for commercial kitchens, architectural installations, or industrial structures, selecting the appropriate grade and finish maximizes lifespan and performance. Explore our full range of premium stainless steel products to find the ideal solution for your next project and ensure enduring quality.