304 жана 316 stainless steel differ mainly in corrosion resistance and chemical composition. 304 is ideal for indoor use, kitchens, and furniture due to its chromium and nickel content. 316 contains molybdenum, boosting resistance to saltwater, chlorides, and harsh outdoor conditions, making it perfect for coastal buildings, poolside railings, or outdoor elevator doors. Choosing the right grade ensures long-term durability and lower maintenance costs.

1. Chemical Composition Differences

1.1 Chromium and Nickel Content

Chromium and nickel are the primary elements that define corrosion resistance in stainless steel. 304 contains 18–20% chromium and 8–10.5% nickel, providing strong durability for indoor applications like kitchen counters or furniture. 316 has slightly higher nickel, around 10–14%, improving toughness in harsher environments.

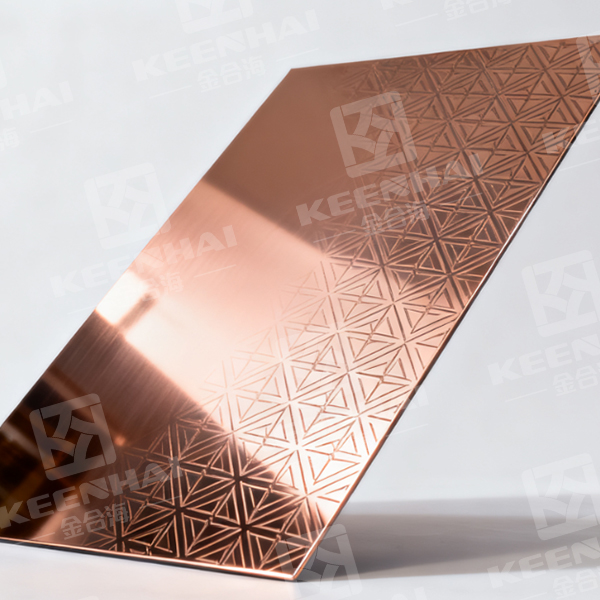

For example, architects often choose Stainless Steel Metal Plate for indoor partitions and decorative panels because this balance of chromium and nickel ensures the surface stays smooth and shiny over years.

1.2 Presence of Molybdenum in 316

The major difference in 316 stainless steel is the addition of 2–3% molybdenum, which 304 lacks. This element enhances resistance to chlorides and saltwater, making 316 the preferred choice for outdoor façades, swimming pool areas, or coastal architecture.

For instance, Stainless Steel Exterior Wall panels made from 316 maintain their polished appearance and resist rust even in harsh seaside conditions. 304 in the same setting would start showing corrosion signs much sooner.

1.3 Impact of Minor Elements

Minor elements such as carbon, manganese, and silicon influence the steel subtly but significantly. Both 304 and 316 limit carbon to ≤0.08% to prevent carbide precipitation during welding, protecting against localized corrosion. Manganese and silicon enhance strength and oxidation resistance, especially in high-temperature or industrial applications.

When using high-quality Metal Stainless Steel Sheet for elevator cladding or partitions, understanding these minor elements ensures the steel performs reliably under stress and environmental exposure.

| Element | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Chromium (Cr) | 18–20% | 16–18% |

| Никель (Ni) | 8–10.5% | 10–14% |

| Molybdenum (Mo) | 0% | 2–3% |

| Carbon (C) | ≤0.08% | ≤0.08% |

| Manganese (Mn) | ≤2% | ≤2% |

| Silicon (Si) | ≤1% | ≤1% |

By knowing the differences in chromium, nickel, molybdenum, and minor elements, builders and designers can choose the right stainless steel grade for indoor or outdoor projects, balancing cost, durability, and corrosion resistance.

2. Corrosion Resistance Comparison

2.1 Resistance to Chloride and Saltwater

316 stainless steel clearly outperforms 304 in chloride-rich environments due to its molybdenum content. This makes it the ideal choice for coastal buildings, marine structures, and poolside installations.

For instance, when specifying panels for a seaside hotel façade, designers often use Дат баспас болоттон жасалган лифттин эшиги in 316 grade to ensure long-term rust resistance and maintain a polished look, whereas 304 would require frequent maintenance to avoid pitting corrosion.

2.2 Performance in Acidic Environments

Both 304 and 316 are resistant to many acids, but 316 has the edge in stronger chemical or industrial exposures. Acid rain, cleaning agents, or chemical fumes can slowly attack 304 surfaces over time. By contrast, 316 resists localized corrosion better, making it suitable for laboratory countertops, chemical plant fittings, and outdoor cladding near urban pollution.

2.3 Long-Term Rust Prevention

For projects requiring decades of maintenance-free performance, 316 is usually the safe bet. Whether it’s exterior cladding, coastal handrails, or elevator doors, the extra corrosion resistance ensures structures stay visually appealing and structurally sound.

A practical tip: using high-quality materials like Stain Steel Sheets in 316 grade for outdoor applications can dramatically reduce maintenance costs and prevent premature rusting, while 304 remains suitable for indoor panels or protected areas.

| Environment | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Coastal/Marine | Moderate, may pit | Excellent, long-term resistance |

| Acidic exposure | Good | Excellent |

| Outdoor structures | Moderate, requires maintenance | Excellent, low maintenance |

Understanding the specific corrosion resistance differences between 304 and 316 ensures that you select the right stainless steel for your environment, preventing rust issues and extending the lifespan of your projects.

3. Mechanical Properties

3.1 Tensile Strength and Hardness

Both 304 and 316 stainless steel exhibit strong tensile strength and hardness, making them reliable for structural and decorative applications. 316 usually shows slightly higher tensile strength, which is beneficial in high-stress environments such as outdoor façades or elevator doors.

For example, using Metal Stainless Steel Sheet in 316 grade for elevator panels ensures that the panels resist deformation under constant use while keeping a polished finish. 304 performs well indoors, but may require thicker panels in high-traffic areas to match 316’s strength.

3.2 Ductility and Flexibility

Both grades maintain good ductility, allowing them to be bent, rolled, or formed without cracking. This makes 304 ideal for indoor railings, furniture frames, and kitchen equipment, while 316 is preferred for coastal handrails or exterior decorative features, where the metal must flex slightly under wind or thermal expansion.

Designers often specify 316 for outdoor curtain walls and façades, ensuring the metal expands and contracts safely without compromising the structure or finish.

3.3 High-Temperature Performance

304 and 316 can both withstand elevated temperatures, but 316 is slightly more resistant to oxidation at high heat due to its molybdenum content. Applications include industrial piping, outdoor lighting fixtures, and heat-exposed panels.

In practice, 304 works fine for indoor kitchen hoods or furniture near heat sources, whereas 316 is preferred in outdoor structures exposed to sunlight or industrial exhaust, maintaining integrity without discoloration or warping.

| Property | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Тартуу күчү | 505–750 MPa | 515–760 MPa |

| Hardness (Brinell) | 123–217 HB | 123–217 HB |

| Ductility | Good | Good, slightly better in high stress |

| High-Temp Resistance | Up to 870°C | Up to 925°C |

Selecting the right stainless steel grade based on mechanical properties ensures durability, structural reliability, and long-term aesthetic appeal, whether it’s for indoor furniture or outdoor elevator doors.

4. Common Applications

4.1 304 Stainless Steel Typical Uses

304 stainless steel is widely used for indoor projects where the environment is less aggressive. Typical applications include kitchen counters, indoor railings, furniture frames, and decorative panels.

For instance, Stainless Steel Metal Plate is often chosen for indoor partitions or cabinet faces, offering a smooth, corrosion-resistant finish that holds up over years without extra maintenance. 304 performs well indoors because it resists normal wear and occasional moisture but isn’t ideal for high-chloride environments.

4.2 316 Stainless Steel Typical Uses

316 stainless steel is the go-to for outdoor or high-corrosion environments. It is commonly used for coastal façades, swimming pool handrails, outdoor furniture, chemical plant fittings, and elevator doors.

A practical example: using Дат баспас болоттон жасалган лифттин эшиги in 316 grade ensures long-term durability and rust-free operation in coastal hotels or high-traffic commercial buildings. Another example is Stainless Steel Exterior Wall panels for seaside resorts, which maintain a polished, corrosion-free surface over decades.

4.3 Selection Guidelines Based on Environment

When choosing between 304 and 316, consider the exposure to moisture, salts, chemicals, and temperature fluctuations. Here’s a quick reference:

| Environment | Recommended Grade |

|---|---|

| Indoor kitchens, furniture | 304 |

| Coastal or marine applications | 316 |

| Outdoor façades and high-humidity areas | 316 |

| Industrial chemical exposure | 316 |

| Low-corrosion indoor partitions | 304 |

For any project exposed to chlorides, saltwater, or chemical cleaning agents, 316 is the safer choice. For protected indoor settings, 304 offers excellent performance at a lower cost. Using high-quality materials like Stain Steel Sheets ensures both grades meet performance expectations without compromising aesthetics.

5. Cost and Availability

5.1 Price Comparison Between 304 and 316

316 stainless steel is generally more expensive than 304 due to the addition of molybdenum and slightly higher nickel content. On average, you can expect 316 to cost 20–40% more than 304, depending on thickness, finish, and supplier.

For example, when specifying Stain Steel Sheets for a coastal hotel exterior, the extra investment in 316 ensures long-term corrosion resistance and lower maintenance costs, which often offsets the initial price difference over time. Meanwhile, 304 is cost-effective for indoor furniture, railings, or kitchen equipment, where exposure to harsh elements is minimal.

5.2 Global Supply and Market Trends

Both 304 and 316 stainless steel are widely available globally, but 316 can occasionally experience supply fluctuations due to molybdenum demand or nickel price spikes. Large-scale projects, especially in marine or chemical industries, often plan procurement months in advance to ensure consistent quality and availability.

High-quality Metal Stainless Steel Sheet suppliers now provide reliable 316 stock in multiple finishes, making it easier to source for commercial and residential projects. 304 remains widely stocked and easier to obtain, which is ideal for quick-turn indoor projects or small-scale fabrications.

| Grade | Relative Price | Availability |

|---|---|---|

| 304 | Lower | Widely available, short lead time |

| 316 | Higher | Available, may need planning for large orders |

Budget, project environment, and timeline determine whether 304 or 316 is the right choice. For long-term outdoor durability, high-chloride environments, or high-traffic commercial areas, investing in 316 pays off, while 304 works perfectly for indoor, low-risk applications.