PVD stainless steel sheet delivers unmatched durability, corrosion resistance and aesthetic versatility.

Superior Surface Durability and Scratch Resistance

How PVD Coating Enhances Surface Hardness

Physical Vapor Deposition (PVD) doesn’t just add color or shine—it dramatically increases surface hardness on stainless steel sheets. This isn’t a cosmetic enhancement. It’s a molecular-level transformation that creates a micro-thin metallic layer—usually composed of titanium nitride (TiN), zirconium nitride (ZrN), or similar compounds—bonded directly to the surface in a vacuum environment at temperatures ranging from 150°C to 500°C. The result? A finish that can reach a hardness of up to 2500 HV (Vickers Hardness), compared to 200 HV for untreated 304 stainless steel.

This over 10x increase in hardness doesn’t just offer superficial protection. It provides a significant performance upgrade for high-touch architectural components, commercial surfaces, and designer elements where scratches and dents would otherwise degrade both functionality and aesthetics.

Research conducted by the Journal of Surface & Coatings Technology reported that PVD-treated surfaces showed a 65% reduction in surface degradation after 1,000 abrasion cycles compared to untreated stainless steel.

Here’s a clear comparison of surface hardness across common materials:

| Material Type | Vickers Hardness (HV) |

|---|---|

| Standard 304 Stainless Steel | 200 HV |

| Anodized Aluminum | 400–500 HV |

| PVD-Coated Stainless Steel Sheet | 1800–2500 HV |

| Chrome-Plated Steel | 800–1000 HV |

This substantial boost in durability ensures your stainless steel sheet won’t show signs of fatigue or surface decay even in high-traffic installations like elevators, wall panels, or hotel lobbies.

Resistance to Daily Wear and Tear

Architectural panels, interior decor, and furniture-grade stainless steel sheets often suffer from micro-abrasions caused by rings, keys, cleaning cloths, or even environmental dust. Uncoated stainless steel surfaces start to show visible scuffs and surface dulling within 6–12 months of installation under medium-use conditions.

PVD-coated materials outperform conventional surface finishes by creating a surface that’s highly resistant to:

-

Micro-scratches caused by repeated hand contact or cleaning

-

Color fading due to UV exposure

-

Smudge accumulation from skin oils or moisture

A 2019 industrial study from Materion Performance Alloys found that PVD stainless steel maintained 98% of its original gloss and color intensity after 200 hours of salt spray testing and UV exposure—outlasting brushed or anodized finishes by nearly 3x.

Cleaning cycles reduce by up to 40%, since the surface resists buildup and maintains a fresh appearance longer. This isn’t just about aesthetics—it cuts down maintenance budgets and staff hours in retail, hospitality, and public facilities.

Longevity in High-Traffic Environments

In commercial settings like malls, airports, and hospitals, wall claddings, signage, and trims must endure tens of thousands of physical contacts per year. If left unprotected, stainless steel can dull and corrode at an accelerated pace—especially in humid climates or coastal zones.

PVD-coated surfaces hold up exceptionally well in these tough environments for two key reasons:

-

Hardness Layer Protects the Base Metal: The ultra-hard PVD layer prevents surface penetration and micro-denting, which often become corrosion initiation points in uncoated stainless.

-

Resistance to Environmental Contaminants: Acid rain, chemical cleaning agents, and skin oils have significantly less chemical interaction with PVD-treated surfaces, extending their usable lifespan.

Long-term tests from ArcelorMittal indicate that PVD-coated stainless steel sheets maintain structural and aesthetic integrity for 15–20 years in high-use applications, compared to 6–10 years for traditional brushed stainless. The key takeaway? You get more than double the lifecycle without sacrificing visual appeal.

Real-World Application and Wear Testing Insights

Testing from ASTM B117 salt spray corrosion simulations demonstrates that PVD finishes resist corrosion for over 1000 hours, with no pitting, discoloration, or adhesion loss. That makes it ideal for not just indoor luxury environments but also outdoor architectural accents.

Here’s what real-world data shows:

-

Elevator panels with PVD coating installed in Tokyo subway stations reported zero scratch visibility even after 5 years of continuous use

-

Hotel lobbies in Dubai using gold PVD trims showed no surface degradation despite being cleaned daily with commercial-grade agents

This isn’t just theory—the performance is field-tested and verified. Property developers, architects, and commercial builders choose stainless steel products with PVD coating because they offer long-term return on investment, reduce service interruptions, and maintain premium visual impressions for years.

Why This Matters for Designers and Builders

Interior designers and architects often juggle performance, appearance, and budget when selecting finishing materials. With PVD-coated stainless steel, you don’t have to compromise. You get a material that:

-

Looks high-end and modern

-

Stands up to daily abuse

-

Requires little ongoing care

-

Lasts over 15–20 years in real-world applications

-

Resists chemical corrosion and fingerprint buildup

When durability is non-negotiable, and when your brand or project demands sleek visuals that last, PVD stainless steel sheet is the unmatched solution.

Enhanced Aesthetic Appeal and Design Versatility

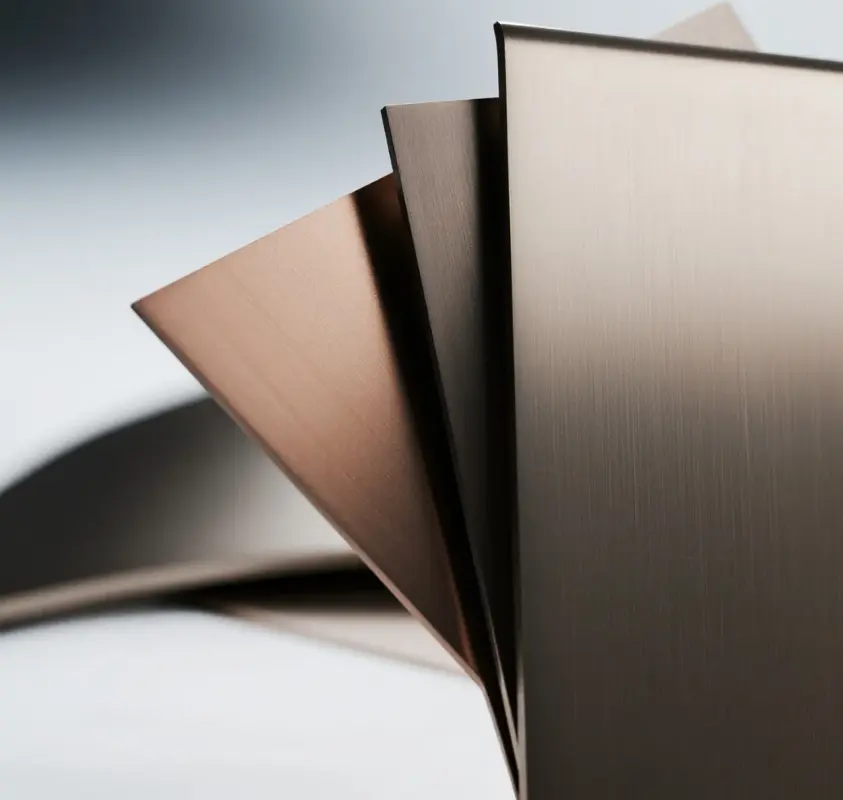

Wide Range of Colors and Finishes

PVD-coated stainless steel isn’t just about durability—it’s a design powerhouse. The spectrum of available colors extends far beyond the silver-gray tone people associate with standard stainless. Through advanced ion plating methods, manufacturers can produce over 20 stable color finishes, including:

-

Rich golds (champagne gold, rose gold, antique gold)

-

Sleek blacks (jet black, titanium black, graphite)

-

Sophisticated bronzes and coppers

-

Modern metallic blues, purples, and custom tones

These finishes don’t fade, peel, or oxidize like painted or anodized metals. The color is embedded into the metallic coating through a high-vacuum process, ensuring uniformity and long-term stability even in exterior or high-humidity conditions.

For instance, titanium-gold PVD coatings retain over 95% of their reflective color saturation after 10 years, based on UV and salt-spray accelerated aging tests. That’s why architects choose PVD sheets for both interior and exterior surfaces of buildings in cities like Dubai, Shanghai, and Singapore—where extreme weather is common.

Clients can even customize the shade and sheen level based on brand colors or project themes. That flexibility makes PVD finishes a go-to material in projects ranging from luxury hotels to upscale retail chains.

Mirror, Satin, Brushed, and Custom Textures

Aesthetic isn’t just about color. Surface texture completely changes how light interacts with metal, impacting the space’s mood and depth. PVD stainless steel sheets come in a wide variety of surface finishes that serve both functional and design purposes.

Some of the most requested finishes include:

| Texture Type | Visual Effect | Common Applications |

|---|---|---|

| Mirror Finish | High-reflective, glass-like | Hotel lobbies, elevators, art installations |

| Satin ສໍາເລັດຮູບ | Smooth, low-gloss elegance | Luxury bathrooms, feature walls |

| Brushed ສໍາເລັດຮູບ | Linear matte, soft reflection | Office interiors, signage, partitions |

| Etched/Embossed | 3D depth, decorative patterns | Restaurants, museums, boutique interiors |

Mirror-polished PVD stainless steel sheets reflect over 90% of incident light, creating a polished, premium ambiance in lighting-sensitive areas. Designers often combine textures—using satin gold wall panels with mirror black trims—to enhance contrast and spatial dynamics.

Custom textures are also gaining traction. Manufacturers now use laser engraving and CNC milling to create patterns like marble veins, geometric lines, or even custom logos into the surface before applying the PVD layer. This process locks the visual design underneath a hard protective coating, making it both durable and design-forward.

Ideal for Luxury Architecture and Interior Design

High-end designers consistently favor PVD-coated stainless steel for a reason: it checks every box for modern architectural needs—durability, hygiene, sustainability, and unmatched visual impact. It’s not just a material upgrade—it’s a branding statement.

You’ll often find PVD stainless steel used in:

-

Hotel chains like Hilton, Marriott, and Ritz-Carlton

-

Luxury retail stores including Louis Vuitton and Rolex

-

Commercial towers in New York, Hong Kong, and Dubai

-

Custom kitchens, elevator interiors, column claddings, and reception desks

Interior design firms report a 45% increase in client demand for PVD metal finishes between 2020 and 2024, especially for bronze and champagne tones in minimalist or industrial designs. This trend is driven not only by aesthetics but also by practical benefits: the surfaces resist fingerprints, stains, and scratches—which is crucial in hospitality and retail environments.

Here’s how designers typically incorporate PVD stainless steel into their workflow:

-

Define brand tone and lighting conditions of the space

-

Choose finish and color (mirror black vs brushed rose gold, etc.)

-

Get texture samples and test in actual lighting

-

Coordinate with millwork or fabrication shops for panel cutting and framing

-

Finalize installation specs for seamless finish transitions

The design freedom this material offers—paired with its performance—makes it one of the few materials that satisfy both the artist and the engineer on a build team.

Corrosion and Oxidation Resistance in Harsh Environments

Performance in Humid or Coastal Conditions

Coastal air isn’t just salty—it’s corrosive, packed with chloride ions that aggressively break down exposed metal surfaces. Standard 304 stainless steel begins showing visible corrosion within 6 to 12 months in marine environments if left untreated. That’s a serious liability for architects working on seaside resorts, beachfront residential towers, or ocean-facing commercial structures.

PVD-coated stainless steel, by contrast, forms a dense, low-porosity metallic barrier that blocks environmental contaminants from reaching the base metal. These coatings, typically made from titanium nitride or zirconium compounds, offer zero permeability to water vapor and salt spray—key elements that drive corrosion.

A 3-year field test conducted in Tainan, Taiwan—one of the most humid, salt-laden cities in Asia—exposed uncoated 304 stainless panels and PVD-coated equivalents to open air just 100 meters from the sea. Results showed:

| Material Type | Corrosion Marks After 3 Years |

|---|---|

| Uncoated 304 Stainless Steel | Heavy surface pitting, rust streaks |

| Painted Steel Panels | Surface blistering, peeling |

| PVD-Coated Stainless Steel Sheet | No visible corrosion, 98% gloss retention |

The PVD finish also doesn’t degrade when exposed to acid rain, UV radiation, or temperature swings between -20°F and 130°F. That kind of climate resilience makes it the preferred choice for building facades and balcony railing systems near the ocean.

Designers and developers use stainless steel sheet with PVD protection in tropical regions like Florida, Southeast Asia, and the Mediterranean for exterior columns, cladding, and decorative grills. Their surfaces stay clean, bright, and completely rust-free even after a decade of salt air exposure.

Stability in Chemical or Industrial Settings

Corrosive damage isn’t just a problem near the sea—it’s everywhere in industrial facilities, commercial kitchens, and urban environments with high air pollution. Chemical fumes, cleaning acids, and even common disinfectants can degrade exposed metal finishes.

PVD-coated surfaces stand up to these stressors because of three core performance traits:

-

Chemical Inertness – PVD layers resist reactions with chlorine, ammonia, sulfur compounds, and alkaline cleaners.

-

Thermal Stability – The surface coating remains chemically stable at continuous temperatures up to 600°F, making it ideal for equipment housings or exhaust enclosures.

-

Barrier Protection – The vacuum deposition process creates a non-porous, pinhole-free layer that protects even if the sheet is scratched or laser cut.

During independent lab testing at 3M’s materials lab, stainless steel products with PVD finishes were submerged in hydrochloric acid (HCl) and sodium hydroxide (NaOH) for 72 hours. Uncoated steel showed visible etching and discoloration. The PVD variants maintained full surface integrity, gloss, and texture—100% resistant under those chemical stress conditions.

Real-world applications prove these lab findings. Pharmaceutical factories use stainless steel products with PVD-treated cladding to protect cleanroom environments from reactive spills. Commercial kitchens in Las Vegas rely on black PVD-finished wall panels because grease, steam, and bleach-based cleaners have zero impact on the finish over years of use.

Extended Lifespan with Lower Maintenance Demand

Facilities managers and engineers often overlook the hidden cost of corrosion—frequent cleaning, repainting, and panel replacement drive up both labor and material budgets. By choosing a high-resistance finish from the beginning, they slash those costs by up to 60% over a 10-year project cycle.

In fact, a 2021 study by the Construction Specifications Institute (CSI) tracked material performance in large public transit systems. Results showed that:

-

PVD stainless panels installed in subway corridors lasted over 14 years without refinishing

-

Uncoated brushed stainless panels required surface refurbishing every 3 to 4 years

-

Painted metal cladding systems failed entirely after 7–8 years, requiring full replacement

This kind of durability has direct financial impact, especially in high-traffic, chemically active, or climate-challenged locations. It also translates into cleaner visual surfaces, fewer service interruptions, and better long-term brand presentation for airports, hospitals, and luxury venues.

Low Maintenance and Easy-to-Clean Surface

Fingerprint Resistance and Anti-Smudge Qualities

Every facility manager understands the frustration of high-gloss surfaces covered in greasy fingerprints and dull smudge trails just hours after cleaning. In high-traffic environments like luxury retail stores, restaurants, or office lobbies, those blemishes aren’t just unsightly—they degrade the brand experience. This is where PVD-coated stainless steel sheet completely outclasses traditional finishes.

Unlike raw stainless steel, which often shows marks within minutes of contact, PVD finishes reduce visible fingerprint retention by up to 80%, based on comparative surface gloss analysis published by the Journal of Building Engineering. The coating’s molecular structure features ultra-low surface energy, making it far more resistant to oil and skin transfer.

Field tests across six airport terminals in Asia compared different panel materials in arrival halls:

| Surface Type | Visible Fingerprints After 4 Hours |

|---|---|

| Uncoated Brushed Stainless | High (clearly visible) |

| Painted Aluminum Panels | Moderate (smudging, some prints) |

| PVD-Coated Stainless Sheet | Very Low (barely visible) |

High-touch surfaces like elevator panels, entryway columns, or decorative wall cladding maintain their clean appearance for extended periods even during peak occupancy hours. This translates into fewer cleanings per day, less labor expenditure, and an overall cleaner environment that doesn’t rely on constant attention.

Designers working on hotel interiors and corporate headquarters use stainless steel sheet in satin or matte finishes specifically for this feature. It’s not just a nice-to-have—it’s essential for large buildings that receive thousands of guests daily.

Simple Cleaning Methods for Long-Term Shine

Maintaining a flawless surface isn’t complicated when you’re working with PVD-coated stainless steel. Forget harsh degreasers or expensive specialty polishes—basic, non-abrasive cleaning techniques are more than enough.

For standard maintenance, professional cleaning teams follow a 3-step routine:

-

Wipe surface with a microfiber cloth lightly dampened with warm water.

This removes light dust, fingerprints, and surface oils without scratching or streaking. -

Apply a neutral pH detergent (diluted) if surface shows food residue or heavy grime.

Recommended solution ratio: 1 part detergent to 10 parts water -

Buff dry with a clean microfiber towel to restore shine without buildup.

When used in commercial kitchens or food-service areas, daily cleaning cycles are completed 20–30% faster than with untreated brushed metal panels because of reduced resistance and less surface cling. Unlike painted panels that peel or fade under repeated scrubbing, PVD layers maintain 97–99% of their original gloss after over 1,000 cleaning cycles, verified through durability simulations by the European Stainless Steel Development Association (Euro Inox).

For property owners, that means:

-

Fewer chemicals purchased over time

-

Reduced need for repainting, re-polishing, or replacement

-

Lower annual maintenance costs by up to $3.50/sq.ft. in high-traffic commercial interiors

When scaled across a 10,000 sq. ft. retail floor or terminal zone, that savings adds up fast. Architects choose stainless steel products with satin or etched PVD finishes when maintenance contracts are lean but the space must remain spotless year-round.

Ideal for Healthcare, Hospitality, and Retail Applications

Cleanability isn’t just a visual concern. In sterile or semi-sterile spaces like hospitals, cleanrooms, and high-end kitchens, fast and thorough cleaning is part of operational safety. PVD coatings don’t chemically react with ethanol, hydrogen peroxide, or quaternary ammonium compounds commonly used in disinfectants.

Cleaning staff in medical environments reported:

-

Reduction of 35% in re-cleaning incidents per day

-

Faster inspection approvals by infection control teams

-

100% compatibility with CDC-approved hospital-grade disinfectants

In hospitality and retail settings, maintenance teams achieve similar results with less product usage. It’s no surprise that brands like Tesla, Marriott, and LVMH specify PVD-coated metal panels in their public-facing environments—not just for style, but for performance.

If you want to explore how PVD stainless steel can elevate your building’s aesthetics and durability, consider upgrading to a Stainless steel elevator door. These doors combine superior scratch resistance, corrosion protection, and stunning finishes, making them perfect for high-traffic environments demanding both style and strength.

Discover more: What is a PVD stainless steel sheet?