Choosing the right material for large-scale projects requires balancing performance and reliability. Buyers consider environmental exposure, load demands, and long-term maintenance when deciding between Inox and stainless steel. Standardized grades reduce ambiguity, while verified suppliers provide predictable quality. Aligning these factors ensures that projects are completed on schedule, with consistent finishes and minimal risk of rework, giving teams confidence in both procurement and engineering decisions.

1. Understanding Material Requirements for Large-Scale Projects

When planning large-scale projects, selecting the right material is critical to ensure performance, durability, and cost-effectiveness. In real projects, teams rarely argue over the terminology itself, but clarity in grade ensures procurement accuracy. For large-scale installations, engineers and buyers must evaluate environmental conditions, load requirements, and surface expectations before finalizing material specifications. These decisions not only affect the project’s lifespan but also streamline procurement and fabrication processes, reducing risk of delays or costly rework.

1.1 Evaluating Environmental Conditions: Indoor vs Outdoor

Environmental exposure plays a major role in material selection. For outdoor applications, materials must resist moisture, UV radiation, and chemical exposure, while indoor projects focus more on wear resistance and aesthetic durability. For example, architectural panels or railings installed near coastal zones must withstand salt corrosion, making high-grade stainless steel sheets critical. For indoor environments like shopping malls or office interiors, corrosion resistance remains important, but surface finish and ease of cleaning often take priority. Using stainless steel sheets with proven corrosion-resistant properties ensures that components retain both function and appearance over time. Buyers should consider these environmental factors in stepwise evaluation:

-

Identify exposure type (moisture, chemicals, sunlight).

-

Assess duration and intensity of exposure.

-

Select materials with the appropriate corrosion resistance rating.

1.2 Assessing Load, Stress, and Durability Needs

Structural performance is another core consideration. Large-scale projects often involve components like structural frames, support beams, or façade panels that must bear significant loads or stresses over decades. Evaluating tensile strength, yield strength, and fatigue resistance allows engineers to choose grades that will maintain stability under varying operational conditions. Below is an example of key mechanical properties for common stainless steel grades:

| Material Type | Yield Strength (MPa) | Tensile Strength (MPa) | Typical Application |

|---|---|---|---|

| 304 Stainless Steel | 215 | 505 | Interior panels, railings |

| 316 Stainless Steel | 290 | 580 | Outdoor cladding, coastal installations |

| 430 Stainless Steel | 210 | 505 | Decorative panels, light-duty structures |

For buyers managing bulk procurement, verifying that suppliers can provide consistent grade quality across thousands of square meters is essential.

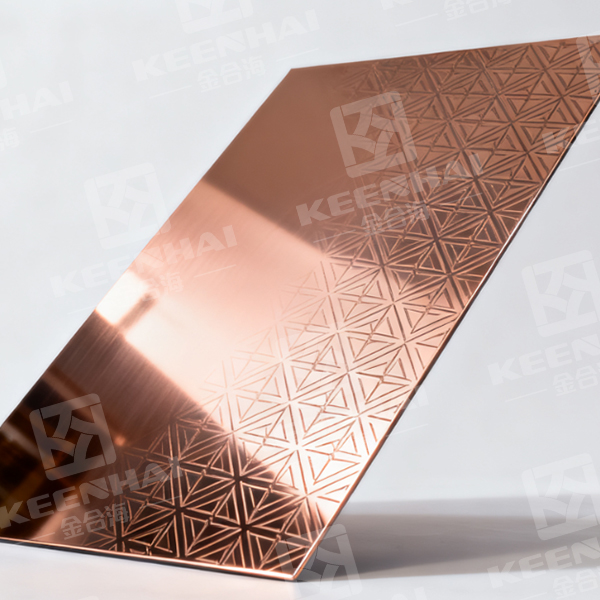

1.3 Determining Surface Finish and Aesthetic Expectations

Surface finish directly impacts both aesthetics and maintenance requirements. Brushed, polished, or mirrored finishes may be specified for visible architectural components, while concealed structural parts prioritize functional performance. Large-scale projects often require coordination between architects, engineers, and fabricators to ensure the selected finish aligns with both design intent and long-term durability. For example, metal stainless steel sheets in façade panels must maintain a uniform finish across large areas to prevent visual inconsistency and reduce cleaning costs. Practical steps for surface selection include:

-

Confirm design requirements with the architect or client.

-

Match finish to environmental and maintenance conditions.

-

Verify that the supplier can consistently deliver the chosen finish across the required volume.

Incorporating these assessments at the early procurement stage ensures that large-scale projects proceed smoothly, with materials that meet both technical and aesthetic standards. Choosing the right stainless steel product from trusted sources significantly reduces risk, saves time, and ensures project quality from design to installation.

2. Comparing Inox and Stainless Steel Grades

Selecting the right grade between Inox and stainless steel significantly impacts project performance and procurement efficiency. In practical projects, engineers often treat Inox and standard stainless steel as interchangeable, but understanding subtle differences in composition and mechanical behavior can optimize material selection, reduce errors, and ensure long-term durability. Evaluating chemical composition, corrosion resistance, and cost-effectiveness for bulk orders helps buyers make informed choices without compromising performance or budget.

2.1 Key Chemical Compositions and Mechanical Properties

The chemical makeup defines how a steel grade behaves under stress, heat, and environmental exposure. For instance, 304 stainless steel typically contains 18% chromium and 8% nickel, offering a balanced combination of corrosion resistance and tensile strength, whereas 316 stainless steel adds 2–3% molybdenum for enhanced marine and chemical resistance. Inox variants often follow similar austenitic structures but can differ in trace elements affecting hardness and machinability.

| Grade | Chromium (%) | Nickel (%) | Molybdenum (%) | Yield Strength (MPa) | Tensile Strength (MPa) |

|---|---|---|---|---|---|

| 304 Stainless Steel | 18 | 8 | 0 | 215 | 505 |

| 316 Stainless Steel | 16–18 | 10–14 | 2–3 | 290 | 580 |

| 430 Stainless Steel | 16–18 | 0–0.75 | 0 | 210 | 505 |

For large-volume projects, verifying that suppliers can deliver consistent mechanical properties across the order is crucial. High-quality stainless steel metal plates ensure predictable behavior during fabrication and installation.

2.2 Corrosion Resistance and Long-Term Performance

Corrosion resistance is often the decisive factor in large-scale projects. Both Inox and conventional stainless steel can resist rust in standard environments, but their effectiveness depends on grade, finish, and exposure. Coastal installations demand grades with higher nickel and molybdenum content to combat salt corrosion, while urban façades may tolerate lower-grade options if the material is protected or maintained. Using proven metal stainless steel sheets in these applications ensures uniform performance, even under fluctuating humidity, temperature, or chemical exposure. Steps to evaluate corrosion suitability include:

-

Identify environmental exposure (e.g., marine, industrial, indoor).

-

Match material grade with expected lifespan and maintenance cycles.

-

Confirm supplier testing for pitting, crevice, and general corrosion resistance.

2.3 Cost-Effectiveness of Common Grades for Bulk Orders

Price efficiency matters when procuring thousands of square meters for large-scale projects. While higher-grade stainless steel offers superior corrosion resistance and durability, its cost per unit can be 20–40% higher than standard Inox. Buyers should consider both initial purchase cost and total lifecycle value, including maintenance, replacement risk, and fabrication efficiency. For example, 316-grade sheets might reduce long-term repair costs in coastal applications despite higher upfront investment. Practical steps for cost evaluation:

-

Compare unit pricing from multiple certified suppliers.

-

Factor in lead times and potential logistical costs.

-

Evaluate total lifecycle cost including installation, maintenance, and warranty coverage.

Selecting the right grade based on mechanical, chemical, and economic data ensures that large-scale projects proceed efficiently, reliably, and within budget.

3. Procurement Considerations in Large-Scale Buying

Efficient procurement strategies are critical for large-scale projects, where mistakes in material selection or supplier coordination can result in costly delays. In real projects, teams rarely dispute whether a grade is labeled Inox or stainless steel, but precise terminology ensures smoother purchase orders and reduces miscommunication. Understanding grade availability, delivery logistics, and naming conventions allows project managers to secure materials that meet technical, aesthetic, and budget requirements consistently.

3.1 Availability of Standardized Grades and Supplier Networks

Access to standardized grades directly impacts project continuity. For large-scale orders, relying on suppliers with verified stock of common grades such as 304, 316, or specialty Inox variants minimizes the risk of delays. Global sourcing networks often provide multiple distribution points to accommodate high-volume projects, ensuring consistent supply.

Steps for verifying availability:

-

Confirm certified grade stock levels with multiple suppliers.

-

Check for warehouse locations and shipping reliability.

-

Request batch test certificates to ensure mechanical properties match specifications.

Practical experience shows that sourcing from multiple verified suppliers ensures continuous workflow and prevents bottlenecks in project timelines.

3.2 Lead Times and Logistics for Bulk Material Delivery

Lead times for large-scale deliveries vary significantly based on grade, sheet size, and fabrication needs. Standard 304 stainless steel sheets can ship within 2–3 weeks for bulk orders, whereas specialized Inox grades may require 6–8 weeks due to production constraints. International shipping adds further complexity, including customs clearance, transport insurance, and local delivery scheduling.

To manage logistics efficiently:

-

Confirm exact material dimensions and tolerances before ordering.

-

Schedule deliveries in phased shipments to align with construction milestones.

-

Track shipment progress and maintain real-time communication with suppliers.

Planning logistics proactively ensures that projects avoid costly downtime while maintaining quality standards. Using stainless steel sheet from verified suppliers helps guarantee that the materials arrive on time and meet all specified requirements.

3.3 How Naming Conventions Affect RFQs and Purchase Orders

Clarity in terminology prevents procurement errors. Different suppliers or regions may use “Inox” or “stainless steel” interchangeably, but minor variations in grade naming can create discrepancies in quotes and purchase orders. Buyers should always confirm:

-

Exact grade specifications (e.g., 304 vs 304L)

-

Sheet dimensions, thicknesses, and surface finishes

-

Certifications and compliance documentation

Engineers and procurement teams often find that standardized terminology reduces RFQ back-and-forth, prevents misquoted pricing, and ensures that delivered materials meet project requirements. In practice, stating both the commercial and technical grade in orders provides transparency and safeguards project integrity.

4. Fabrication, Installation, and Project Coordination

Large-scale projects rely not only on selecting the right material but also on how inox or stainless steel products are fabricated, transported, and installed, as this directly affects performance and timeline adherence. In real projects, teams rarely argue over the terminology itself, but clarity in grade and specification ensures procurement accuracy and avoids costly rework. Coordinating engineering, procurement, and fabrication from the early stages ensures that materials meet design tolerances and aesthetic expectations while staying on schedule.

4.1 Custom Fabrication Capabilities and Limitations

Understanding supplier fabrication capabilities is crucial. Custom work involves precise cutting, bending, and finishing, and the process often follows these steps:

-

Verify material grade and thickness according to project specifications.

-

Cut and shape panels using CNC, laser, or waterjet equipment.

-

Perform bending, welding, or perforation operations while maintaining tolerances.

-

Inspect and document the finished parts for dimensional accuracy and surface quality.

For large-format panels, including Metal Stainless Steel Sheet, early discussion of fabrication limits prevents on-site modifications, saving both time and cost.

4.2 Handling, Storage, and On-Site Installation Procedures

Proper handling and storage protect material integrity. Critical steps include:

-

Store sheets in dry, clean areas to prevent corrosion or staining.

-

Use supports, pallets, or racks to avoid scratches or warping.

-

Lift and transport materials carefully, employing cranes or forklifts for heavy sheets.

On-site installation must be methodical:

-

Position panels accurately according to layout plans.

-

Level and align using laser or optical tools to ensure uniformity.

-

Secure panels with the appropriate fasteners, maintaining structural and aesthetic standards.

-

Inspect every section immediately after installation to catch misalignments early.

Teams often assign dedicated supervisors to oversee these steps, ensuring safety and timeline adherence.

4.3 Coordination Between Engineering, Procurement, and Fabrication Teams

Smooth communication between departments is essential for large-scale projects. Effective coordination typically involves:

-

Procurement confirming material availability and lead times.

-

Engineering providing precise tolerances and performance requirements.

-

Fabrication teams reviewing specifications and confirming feasibility.

-

Scheduling weekly meetings or using project management tools to track progress and flag issues.

For example, delays in confirming surface finish or fabrication sequence can halt production, affecting downstream installation. Maintaining real-time updates and standardized documentation keeps all teams aligned, ensuring projects stay on budget and schedule.

5. Cost Management and Risk Mitigation

Managing costs and mitigating risk in large-scale stainless steel projects requires careful planning from procurement to installation. For buyers, the goal is to balance quality, performance, and budget while avoiding surprises that could inflate costs. In real projects, early alignment between engineering and procurement teams prevents costly errors, ensuring material selection, fabrication, and delivery match the planned specifications and timeline.

5.1 Budgeting for Material, Fabrication, and Transportation

Effective budgeting starts with breaking down the costs into clear categories. Critical steps include:

-

Material cost calculation, based on grade, sheet size, and quantity.

-

Fabrication costs, accounting for cutting, bending, welding, and finishing.

-

Transportation and handling fees, including packaging, protection, and delivery logistics.

For example, specifying Stainless Steel Sheet dimensions early avoids last-minute cutting adjustments, which can increase labor and scrap costs. Using a standardized cost model ensures that the total project budget is realistic and actionable.

5.2 Evaluating Total Cost of Ownership for Long-Term Projects

When planning for multi-year projects, total cost of ownership (TCO) extends beyond initial purchase. Key considerations include:

-

Maintenance frequency and cost, including cleaning and corrosion protection.

-

Replacement or refurbishment cycles, based on exposure conditions.

-

Operational impacts, such as downtime during installation or repairs.

Opting for high-quality stainless steel grades reduces TCO by extending service life and minimizing maintenance. Buyers often find that upfront investment in verified materials pays off over time in lower repair, labor, and downtime costs.

5.3 Reducing Procurement Errors Through Standardized Specifications

Procurement errors can significantly affect both cost and schedule. Steps to minimize mistakes include:

-

Defining standardized grades and finishes in the RFQs.

-

Cross-verifying specifications with fabrication teams before orders are placed.

-

Maintaining clear documentation of approved suppliers and product types, including source verification.

Leveraging resources from trusted suppliers like pvdstainlesssteel ensures materials meet the expected grade, dimension, and finish, reducing the risk of rework or replacement. Clear standards also simplify communication across teams, streamlining purchasing, fabrication, and installation.