To obtain an accurate quote, suppliers must understand every aspect of your project, from structural requirements to the exact stainless steel grades and finishes. Including precise panel dimensions, tolerances, and any surface treatments ensures that the quote reflects real-world costs and fabrication complexity. Projects with detailed stainless steel sheets or specialized plates require this level of specificity to avoid miscommunication and rework.

1. Detailed Project Specifications

A precise project specification forms the backbone of a successful stainless steel engineering project. Providing detailed requirements ensures your supplier can quote accurately, reduce waste, and meet deadlines. Clear communication of scope, materials, and tolerances is crucial for both performance and aesthetics.

1.1 Define Project Scope and Structural Requirements

Start by outlining the full project scope, including structural elements, load requirements, and expected environmental conditions. For example, a multi-story office building façade project required stainless steel panels to withstand wind loads up to 120 km/h while maintaining alignment with architectural design lines. Clearly indicate whether panels will serve decorative, protective, or structural functions, as this directly affects material selection and fabrication complexity.

Steps to define scope:

-

List all areas requiring stainless steel elements, including interior and exterior applications.

-

Specify environmental considerations such as exposure to humidity, salts, or chemicals.

-

Include structural load parameters, deflection limits, and attachment methods for panels.

Providing these details upfront allows the supplier to determine precise fabrication methods and avoid costly rework on-site.

1.2 Specify Stainless Steel Grades and Finishes

Selecting the correct stainless steel grade is fundamental. Common grades for architectural projects include 304 and 316 stainless steel sheets, where 316 offers superior corrosion resistance in coastal environments. Finish options—mirror, brushed, or matte—also influence fabrication and maintenance. For instance, a commercial lobby used brushed 304 panels to minimize visible fingerprints while maintaining a polished appearance.

For material reference and technical specifications, suppliers often refer to karatasi ya chuma cha pua products, which detail thicknesses, tolerances, and available finishes. Providing the grade and finish requirements allows your supplier to assess feasibility and prepare accurate quotes efficiently.

1.3 Determine Panel Sizes, Thickness, and Tolerances

Precise panel dimensions and thicknesses are essential for fitting and structural performance. Typical architectural panels range from 1.5mm to 6mm thickness depending on support and span. For complex façade projects, panel tolerances must be tightly controlled to avoid gaps or misalignment.

| Parameter | Typical Range | Notes |

|---|---|---|

| Thickness | 1.5–6 mm | Depends on structural load and finish |

| Panel Width | 300–1200 mm | Larger panels require additional support |

| Panel Height | 600–3000 mm | Must match attachment system |

| Edge Tolerance | ±0.5 mm | Critical for flush alignment |

| Flatness Deviation | ≤2 mm per 1000 mm | Ensures smooth visual appearance |

For projects using specialized materials, such as stainless steel metal plate, providing exact dimensions allows suppliers to quote cutting, bending, and finishing accurately. Clearly indicating tolerances reduces installation delays and material waste, especially on large-scale façade or interior wall projects.

2. Material and Fabrication Requirements

Selecting the right materials and understanding fabrication requirements is critical for accurate project quotes and long-term performance. Suppliers need clear details about the type of stainless steel, fabrication methods, and surface finishes to ensure the final product meets both structural and aesthetic standards.

2.1 Type of Stainless Steel Sheet or Plate Required

Identify whether your project requires stainless steel sheets, metal plates, or specialized stainless components. For instance, interior decorative panels often use thin stainless steel sheets for ease of handling, while structural façade panels may need thicker stainless steel metal plates to withstand wind loads.

Steps to define material type:

-

Determine whether panels are load-bearing or decorative.

-

Specify material grade, such as 304 for general use or 316 for coastal exposure.

-

Indicate size and thickness requirements to match your structural and aesthetic design.

Providing this information upfront allows suppliers to calculate cutting, bending, and fabrication costs accurately and ensures quotes reflect real project needs.

2.2 Special Fabrication Processes (Bending, Laser Cutting, Welding)

Projects often require precision fabrication that goes beyond standard cutting. Typical processes include:

-

Laser Cutting – Used for intricate patterns on façade panels or decorative interiors. Laser precision ensures tight tolerances and clean edges.

-

Bending and Forming – Required for curved or angled panels, where accurate bend radius and angle must be specified to avoid misalignment during installation.

-

Welding and Assembly – Structural panels or multi-piece assemblies need welding specifications, such as TIG or MIG, and post-weld finishing.

For example, a high-end retail façade project used laser-cut stainless panels with precise holes and engraved branding, which allowed seamless installation and consistent alignment across 120 panels. Clearly specifying these fabrication requirements reduces the risk of rework and installation delays.

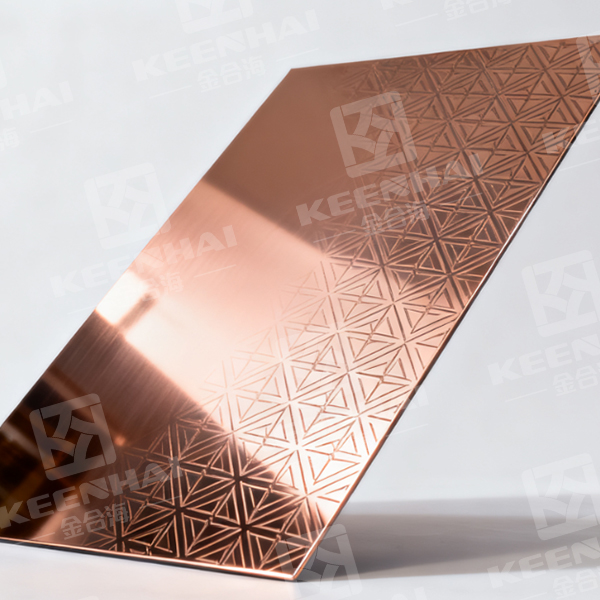

2.3 Surface Treatment and Finishing Options

Surface finish affects aesthetics, durability, and maintenance. Common treatments include:

-

Brushed Finish – Minimizes fingerprints and hides minor scratches.

-

Mirror Finish – Highly reflective surfaces that require careful handling and maintenance.

-

Powder Coating or Polishing – Enhances corrosion resistance and color uniformity.

When suppliers are provided with precise finish details, they can determine whether additional steps like passivation or mechanical polishing are necessary. For large-scale installations, using metal stainless steel sheet with pre-applied finishes can reduce on-site labor and maintain consistency across panels.

Steps to define finishing needs:

-

Identify interior vs. exterior applications.

-

Determine level of gloss or matte required for visual consistency.

-

Specify maintenance expectations to guide surface treatment choice.

Suppliers like pvdstainlesssteel can assist with custom finishes and advise on the best material-finish combination for specific environmental conditions, ensuring both longevity and aesthetic quality.

3. Quantity and Delivery Information

Providing accurate material volumes and clear delivery requirements is essential for suppliers to quote precisely and plan production efficiently. Overlooking these details can lead to delays, cost overruns, or mismatched components on-site. The more precise the data, the smoother the procurement and installation process.

3.1 Total Material Volume Needed

Calculating total material volume goes beyond simply counting panels or sheets. Suppliers need:

-

Exact number of panels or components per project zone.

-

Specific dimensions and thicknesses of each panel, including any allowances for cutting, bending, or fabrication waste.

-

Material type and grade to estimate weight and handling requirements.

For instance, a commercial high-rise façade project required 420 panels of steel sheet stainless, each ranging from 1.5m² to 3m². Providing these figures upfront allowed the supplier to schedule cutting, pre-fabrication, and storage without overproducing, ensuring on-time delivery and cost control.

3.2 Delivery Schedule and Phasing Requirements

A detailed delivery schedule is crucial, particularly for phased construction projects. Suppliers must know:

-

Project milestones and on-site installation dates.

-

Sequence of deliveries for different zones or building levels.

-

Lead times for custom finishes or special fabrication processes.

For example, an airport interior project received materials in three phased shipments, aligned with ceiling and wall installation schedules. This approach minimized storage issues and allowed installers to maintain continuous workflow. Communicating phased delivery requirements early ensures suppliers can optimize production and logistics.

3.3 Packaging and Transportation Considerations

Material protection during transit prevents damage and maintains surface quality. Key points to provide your supplier:

-

Type of packaging needed: shrink-wrap, crates, or protective sheets.

-

Special handling instructions for fragile or finished surfaces.

-

Transportation mode and constraints, including weight limits for elevators or narrow corridors.

For projects using pre-finished panels or karatasi za chuma cha pua, proper packaging and labeling are vital to prevent scratches and maintain uniform finishes. Suppliers can then coordinate logistics to avoid on-site damage and reduce rework costs.

Clear communication of volume, delivery schedule, and handling requirements allows suppliers to prepare precise quotes, allocate resources efficiently, and deliver products that match your project timeline and quality expectations.

4. Technical Drawings and Documentation

Providing accurate and detailed documentation is critical for suppliers to prepare precise quotes and ensure manufacturing aligns with project expectations. Clear drawings and material lists reduce errors, prevent miscommunication, and allow suppliers to plan production efficiently.

4.1 Detailed CAD or Engineering Drawings

Suppliers require precise CAD or engineering drawings to understand the project’s geometry, dimensions, and assembly requirements. These drawings should include:

-

Full panel layouts with exact dimensions and tolerances.

-

Bending, welding, or cutout details clearly annotated.

-

Installation instructions or on-site assembly references.

For instance, a luxury hotel façade project included complex curved panels fabricated from stainless steel metal plate. Detailed CAD files showing curvature radii, joint positions, and hole placements allowed the supplier to pre-fabricate panels with minimal adjustments on-site, saving both time and cost.

4.2 Bill of Materials (BOM) and Component Lists

A comprehensive BOM is crucial for accurate pricing and inventory planning. Suppliers need:

-

Quantities of each type of panel or sheet.

-

Material grades and thicknesses.

-

Hardware components such as screws, brackets, and fasteners.

| Component | Nyenzo | Quantity | Notes |

|---|---|---|---|

| Wall Panel | Karatasi ya Chuma cha pua | 120 | 2mm thickness, brushed finish |

| Roof Panel | Karatasi ya Chuma cha pua | 45 | Polished mirror finish |

| Fasteners | Chuma cha pua | 500 | Include anti-corrosion coating |

Providing this level of detail allows suppliers to calculate costs precisely and avoid supply shortages, ensuring production timelines are met without unexpected delays.

4.3 Reference Standards and Compliance Requirements

Suppliers must know applicable industry standards and compliance requirements, such as ASTM, ISO, or local building codes. This includes:

-

Surface finish classifications for durability and aesthetics.

-

Structural standards for load-bearing panels.

-

Any fire rating, anti-corrosion, or environmental compliance requirements.

For example, a hospital interior project required panels that met ISO 9001 quality control and anti-microbial surface standards. Clear documentation upfront allowed the supplier to select the correct karatasi ya chuma cha pua and fabrication process, ensuring full compliance and smooth installation.

5. Project Support and Coordination Needs

Suppliers that provide strong on-site support and clear communication channels significantly reduce project risks. Early coordination ensures materials are correctly fabricated, delivered on time, and installed without unexpected issues.

5.1 On-Site Consultation or Installation Assistance

For complex stainless steel projects, on-site consultation can prevent costly errors. Suppliers should provide:

-

Visits to measure or verify dimensions before fabrication.

-

Assistance during initial installation phases to guide installers on proper alignment, fixing, and handling.

-

Recommendations for adjustments or sequencing based on real-time site conditions.

For example, a museum interior project using metal stainless steel sheet required precise alignment of decorative panels. Supplier engineers attended on-site during the first phase, guiding the installers on proper bracket placement and panel spacing, which avoided misaligned sections and reduced rework.

5.2 Technical Support During Fabrication

Technical support is essential to ensure that material specifications are correctly interpreted during fabrication. Suppliers should offer:

-

Clarifications on cutting, bending, or welding requirements.

-

Assistance with specialized finishes or surface treatments.

-

Real-time advice for any deviations detected during production.

A commercial high-rise façade project involved multiple panel types with differing thicknesses and finishes. The supplier provided live fabrication support, helping the workshop maintain consistent quality and ensuring all pre-finished stainless steel sheets met the required tolerances.

5.3 Communication Protocols and Approval Workflow

Clear communication protocols between the client, contractor, and supplier are vital. This includes:

-

Defined points of contact for design approvals, change requests, and production sign-offs.

-

Documented timelines for feedback and response to avoid bottlenecks.

-

A structured workflow for addressing on-site modifications or emergency requirements.

For instance, an airport terminal project implemented a stepwise approval system where each batch of panels was reviewed and signed off before shipment. This workflow ensured suppliers could produce accurately without guessing specifications, minimizing delays and maintaining quality.

Suppliers that actively coordinate with your team on-site, during fabrication, and throughout the approval workflow provide peace of mind and help deliver projects on schedule with high-quality outcomes. Integrating technical guidance and structured communication is as important as the materials themselves, and choosing a partner who excels in these areas, such as pvdstainlesssteel, can make a measurable difference in project success.