1. Define Your Wine Cabinet Project Scope

Before requesting a custom quote, you need to lock down the real scope of your wine cabinet project. Suppliers price based on clarity. When dimensions, usage, and storage logic stay vague, quotes drift upward to cover uncertainty. In real residential villas, boutique hotels, and high-end restaurants, projects that define scope early move faster, cost less, and avoid redesign loops later.

In many premium interiors, custom stainless steel wine cabinets already appear during early architectural planning because they tolerate humidity, resist corrosion, and keep a clean visual line across kitchens, lounges, and cellar corridors. That is why projects using materials like stainless steel wine cabinet systems often finalize scope earlier than wood-only alternatives.

1.1 Determine Installation Location and Available Space

Start with the physical environment, not the cabinet itself. Location directly controls structure, ventilation, and cost.

In real-world builds, wine cabinets typically fall into four locations: open kitchens, dining spaces, transitional corridors, and dedicated cellar rooms. Each location introduces different constraints. A kitchen installation often limits depth due to cabinetry alignment, while corridor installations require tighter door swing clearances. Basement cellars usually allow more flexibility but introduce humidity and floor load considerations.

When measuring, follow this practical sequence used by contractors:

-

Measure net wall width, depth, and height, excluding trim and baseboards.

-

Confirm doorway and hallway clearance for cabinet delivery.

-

Identify nearby power supply and ventilation paths.

-

Note any heat sources such as ovens, dishwashers, or direct sunlight.

Skipping these steps leads to redesign costs later, especially in stainless steel installations where tolerances stay tight and finishes expose alignment errors.

1.2 Clarify Intended Use (Residential, Commercial, Display, Storage)

Use defines structure. A wine cabinet built for storage behaves differently from one built for visual merchandising.

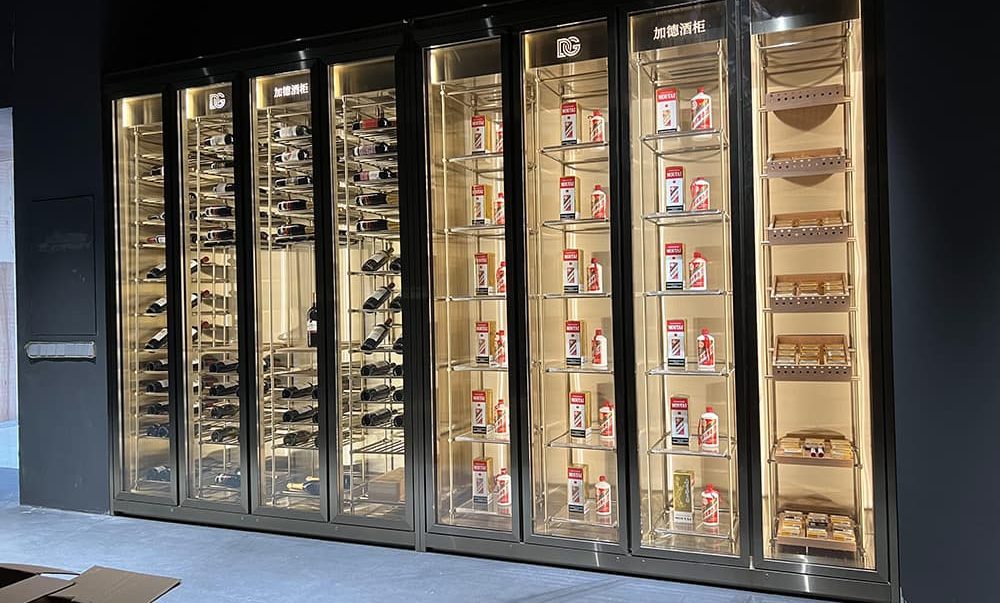

Residential projects often prioritize quiet operation and visual integration with furniture. Commercial environments—restaurants, hotels, wine bars—prioritize durability, access speed, and consistent temperature recovery. Display-focused cabinets emphasize glass coverage and lighting, while pure storage cabinets favor density and airflow.

In hospitality projects, designers often separate functions by zone. For example, a dining room may use open-display stainless steel wine racks for immediate access, while bulk inventory sits in back-of-house cabinets. In those cases, dedicated stainless steel wine rack solutions handle visibility, while enclosed cabinets protect reserve stock.

Be explicit about usage, because suppliers calculate materials, insulation, and hardware based on how often doors open and how bottles rotate.

1.3 Estimate Bottle Capacity and Internal Layout Requirements

Capacity estimates should reflect real inventory, not aspiration. Oversizing increases cost and underutilization; undersizing forces early expansion.

Professionals usually calculate capacity in three layers:

-

Current bottle count

-

Short-term growth (12–24 months)

-

Functional separation (daily-use vs long-term storage)

Cabinet layout also changes with bottle formats. Champagne, Burgundy, and magnum bottles occupy more volume and require adjusted rack spacing. Projects that fail to define this early often face layout revisions after shop drawings begin.

Below is a realistic reference used in commercial and high-end residential planning:

| Project Type | Typical Bottle Capacity | Internal Layout Priority |

|---|---|---|

| Private Residence | 100–300 bottles | Mixed display + storage |

| Restaurant / Wine Bar | 300–800 bottles | Fast access + durability |

| Hotel or Club Cellar | 800+ bottles | Density + zoning |

For projects that mix density with structure, a stainless steel wine rack cabinet often bridges open racks and enclosed storage, allowing visual presentation without sacrificing load stability. When ambient-temperature storage applies—such as short-term holding or decorative walls—some projects also integrate a stainless steel room temperature wine cabinet to reduce mechanical complexity while preserving a consistent material language.

2. Specify Core Design and Material Requirements

Once the project scope is clear, design and material decisions determine whether the quote reflects a functional build or a visual concept only. In real projects—especially restaurants, hotels, and high-end residences—material misalignment causes most mid-project cost revisions. This stage locks cost, durability, and long-term usability.

For premium environments, Датсыз корыч шәраб шкафлары often anchor this stage because stainless steel maintains dimensional stability, resists moisture, and integrates cleanly with glass and lighting systems. That is why many architects finalize structure and material specs before discussing finishes or accessories.

2.1 Select Cabinet Structure and Exterior Materials

Start with structure, not finishes. The cabinet frame controls load capacity, vibration resistance, and long-term alignment.

In commercial builds, fabricators usually specify welded stainless steel frames instead of bolt-only assemblies. Welded frames reduce micro-movement when cabinets hold hundreds of bottles, especially in high-traffic spaces. Residential projects may allow lighter structures, but once bottle counts exceed 200, structural rigidity still matters.

When choosing exterior materials, designers typically decide between three practical approaches:

-

Full stainless steel exterior for durability, moisture resistance, and uniform finish control.

-

Stainless steel frame with glass-dominant frontage to emphasize display and lighting.

-

Hybrid metal–panel systems where stainless steel carries load and panels provide visual softness.

Projects that ignore structural hierarchy often face door misalignment or uneven rack spacing within the first year of use. Structure always comes before appearance, even when the cabinet serves a display role.

2.2 Choose Door Type, Glass Specification, and Finish Options

Door configuration defines daily interaction. Swing clearance, sealing, and glass performance directly affect usability and energy stability.

Designers typically choose between hinged and sliding doors based on space constraints and access frequency. Glass specification then follows usage intensity rather than aesthetics alone. For example, commercial installations often require laminated or tempered glass with thicker profiles to handle repeated opening cycles.

Below is a practical comparison used during specification reviews:

| Element | Residential Preference | Commercial Preference |

|---|---|---|

| Door Type | Hinged, soft-close | Sliding or reinforced hinged |

| Пыяла калынлыгы | 8-10 мм | 10–12 мм |

| Glass Treatment | Low-iron, clear | Tinted or UV-filtered |

| Finish Priority | Visual harmony | Scratch and impact resistance |

Finish selection should align with surrounding materials. Brushed finishes reduce fingerprint visibility in high-touch environments, while polished surfaces suit controlled, low-contact spaces. Finish choice affects maintenance frequency, not just appearance.

2.3 Define Interior Components (Shelving, Racks, Lighting)

Interior configuration determines how efficiently the cabinet works day after day.

Professionals define interiors in a fixed order:

-

Rack type and spacing based on bottle formats and rotation speed.

-

Shelf load ratings to prevent long-term sagging under full capacity.

-

Lighting placement and color temperature to avoid heat concentration and glare.

In mixed-use projects, designers often combine enclosed cabinets with stainless steel wine rack cabinets to balance visibility and storage density. For larger spaces, this logic naturally scales into a stainless steel wine cellar layout, where consistent rack geometry across zones simplifies maintenance and future expansion.

Lighting should support label visibility without overpowering the display. Most high-end projects specify low-heat LED strips integrated into vertical rack lines rather than overhead spotlights. Good lighting reveals structure; poor lighting hides flaws.

3. Identify Technical and Functional Specifications

Once design and materials are fixed, technical specifications determine whether the cabinet performs consistently or becomes a long-term maintenance burden. In real projects, most performance complaints trace back to underdefined cooling logic, humidity mismatch, or ignored noise and ventilation constraints. This section directly affects system cost, operating stability, and user experience.

For projects using Датсыз корыч шәраб шкафлары, technical alignment matters even more because metal structures transfer temperature faster than wood-based systems. That makes correct system specification non-negotiable.

3.1 Cooling System Type and Temperature Zones

Cooling strategy should match how the wine is actually stored and consumed. Single-zone systems work for uniform collections, while dual- or multi-zone systems support mixed inventories such as reds, whites, and sparkling wines stored in the same cabinet.

Professionals usually evaluate cooling options in this order:

-

Define target temperature ranges based on wine categories.

-

Decide zoning logic (single vs multi-zone) according to access frequency.

-

Match compressor capacity to cabinet volume and door-opening cycles.

Below is a practical comparison frequently used during specification reviews:

| System Type | Temperature Range | Typical Use Case |

|---|---|---|

| Single-Zone | 12–14°C | Long-term storage, cellars |

| Dual-Zone | 5–18°C | Mixed red and white collections |

| Multi-Zone | Independent zones | Commercial or display-focused builds |

In restaurant back-of-house areas or private cellar rooms, designers often extend this logic into a stainless steel wine cellar configuration, where consistent cooling across zones simplifies inventory control and reduces system strain.

Cooling capacity must scale with cabinet volume, not just bottle count. Dense layouts with tight rack spacing demand stronger airflow management to avoid temperature stratification.

3.2 Humidity Control and Insulation Standards

Humidity keeps corks stable and labels intact. Most wine storage environments perform best between 55% and 70% relative humidity. Below that range, corks dry out; above it, condensation and mold risks increase.

In stainless steel structures, insulation quality plays a decisive role. Thin insulation forces compressors to cycle more frequently, which raises energy consumption and accelerates component wear. High-quality builds combine rigid insulation panels with thermal breaks at door frames to reduce heat transfer.

Designers often specify humidity control as part of the cooling system rather than a separate module to avoid conflicting controls. A stable cabinet environment always depends on insulation first, electronics second.

3.3 Electrical, Ventilation, and Noise Constraints

Technical performance also depends on how the cabinet integrates into the building.

Before finalizing specs, experienced installers verify the following:

-

Dedicated power supply with stable voltage to protect compressors and control boards.

-

Ventilation clearance at the rear, base, or top, depending on system design.

-

Noise tolerance based on cabinet placement near dining or living areas.

In open-plan residences and hospitality spaces, noise limits usually stay below 40 dB to remain unobtrusive. Ventilation paths must remain clear even after cabinetry or wall panels go in—blocked airflow is one of the most common causes of early system failure.

Electrical and ventilation planning should happen before fabrication, not during installation. Late-stage changes increase labor costs and delay commissioning.

4. Prepare the Information Needed for an Accurate Quote

An accurate quote depends less on how many questions you ask and more on how precise your inputs are. Suppliers price risk into vague requests. When you present clear measurements, realistic budgets, and defined timelines, pricing tightens and revision cycles shrink. This stage turns your project from a concept into a manufacturable request.

4.1 Measurements, Drawings, or Reference Images

Measurements carry more weight than inspiration images, but the best requests include both. In practice, suppliers rely on dimension accuracy first, visual references second.

Provide information in this order:

-

Final installation dimensions: width, height, depth, and any ceiling or wall offsets.

-

Elevation or section drawings, even if they come from a basic architectural plan.

-

Reference images showing layout intent, door direction, and visual density.

For custom wine cabinets integrated into millwork or wall systems, installers often flag conflicts early when drawings show surrounding cabinetry. A 20 mm clearance issue caught here prevents weeks of redesign later.

If your project uses ambient storage rather than active cooling, note that clearly. A stainless steel room temperature wine cabinet requires different structural assumptions and eliminates compressor-related allowances, which directly affects quoted cost and lead time.

4.2 Preferred Budget Range and Cost Priorities

Budget transparency does not weaken your negotiating position; it sharpens it. Suppliers quote differently when they understand where flexibility exists.

Instead of stating a single number, define cost priorities. For example, some projects protect finish quality while accepting simpler interiors, while others invest heavily in structure and racks but keep exterior finishes restrained.

Below is a realistic breakdown suppliers use when balancing specifications:

| Cost Driver | High Priority Impact | Low Priority Trade-off |

|---|---|---|

| Structural Frame | Load capacity, longevity | Reduced wall thickness |

| Cooling System | Stability, zoning control | Limited temperature range |

| Glass & Doors | Visual clarity, durability | Standard profiles |

| Interior Racks | Density, bottle support | Fixed layouts |

Clear priorities guide smarter material substitutions, not arbitrary cost cutting.

4.3 Project Timeline and Delivery Expectations

Timeline clarity prevents rushed fabrication and scheduling conflicts. Quote accuracy improves when suppliers understand how their production fits your build sequence.

Define timeline details explicitly:

-

Target installation date, not just order date.

-

Dependency points, such as flooring completion or wall finishes.

-

Buffer windows for shop drawings, revisions, and approvals.

In commercial builds, delays often come from mismatched expectations—fabrication finishes before the site is ready, or site work finishes before cabinets ship. Aligning production and site readiness protects both cost and quality.

5. Request and Compare Custom Quotes Effectively

At this stage, the difference between a useful quote and a misleading one comes down to structure and comparison logic. Many buyers focus only on the final number and miss critical exclusions, assumptions, or limits. A strong comparison framework exposes real value, not just apparent cost savings.

When projects involve Датсыз корыч шәраб шкафлары, this step becomes even more important because material thickness, fabrication methods, and internal components vary widely behind similar-looking proposals.

5.1 What to Ask Suppliers to Include in the Quote

A professional quote should read like a technical summary, not a sales flyer. Before reviewing price, confirm the quote clearly lists the following items:

-

Material specifications, including steel grade, finish type, and glass thickness.

-

Cooling and control components, with brand or performance range clearly stated.

-

Interior configuration details, such as rack spacing, load ratings, and lighting type.

-

Scope boundaries, specifying what the price includes and explicitly excludes.

If a quote lacks line-item clarity, you cannot compare it fairly, no matter how competitive the total appears. In real commercial projects, unclear scope causes cost creep after approval, not before.

5.2 How to Compare Pricing Beyond the Base Cost

Base price alone hides risk. Experienced buyers compare quotes by isolating performance and durability factors that affect long-term cost.

Use the following comparison logic when reviewing multiple proposals:

| Comparison Factor | Why It Matters | What to Watch |

|---|---|---|

| Structural Method | Affects alignment and lifespan | Welded vs bolt-only frames |

| Материаль калынлык | Determines rigidity and vibration control | Thin panels vs reinforced profiles |

| Cooling Capacity | Impacts temperature recovery | Undersized compressors |

| Interior Load Rating | Prevents rack deformation | Unsupported shelf spans |

Two quotes with similar pricing can deliver very different outcomes once installation, usage, and maintenance begin. Always normalize specifications before judging value.

5.3 Clarifying Revision Limits and Customization Flexibility

Customization rarely ends with the first draft. Smart buyers clarify revision rules upfront to avoid friction later.

Before approving any quote, confirm:

-

Number of included design revisions before price adjustments apply.

-

Cost triggers for changes in size, materials, or layout.

-

Lead time impact caused by late-stage modifications.

In practice, projects that define revision boundaries early move faster and stay on budget. Unrestricted customization sounds attractive but often masks undefined costs.