是的,不锈钢会生锈,但仅限于特定条件。诸如暴露在盐分、高温、划痕、焊点或劣质材料等因素都会损害其保护层。选择合适的不锈钢材质,并定期清洁和维护,生锈现象很少发生,且易于控制,从而保持不锈钢表面光亮耐用,经久耐用。

1. 不锈钢为何不易生锈

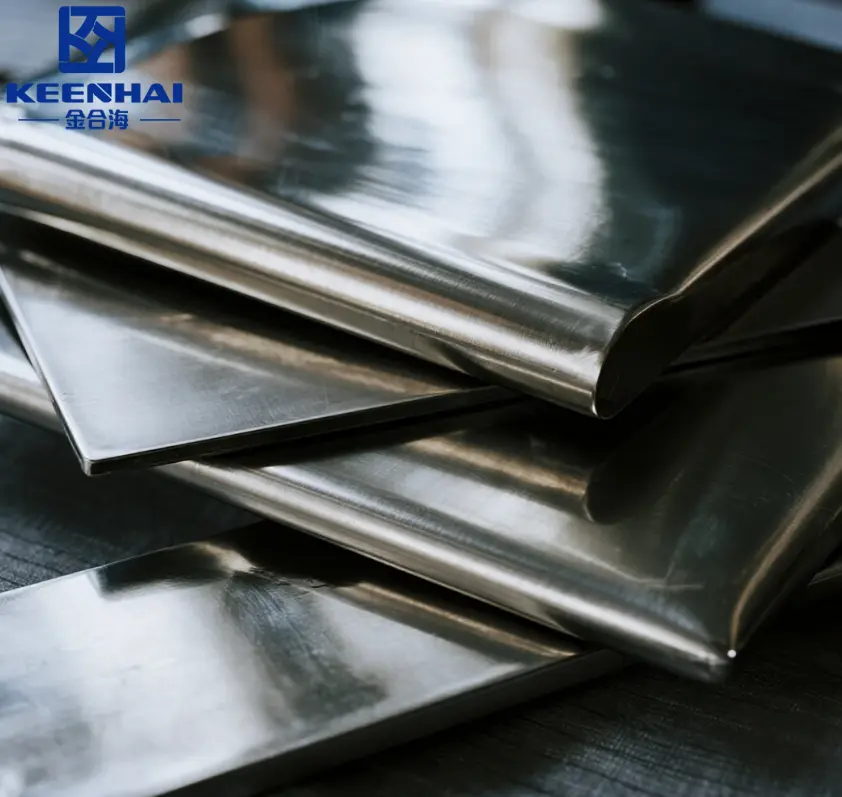

当建筑师设计现代商业大厦或大型公共空间时,外墙材料的选择不仅要考虑美观,还要考虑长期耐用性。在潮湿的城市或沿海地区,许多建筑都采用 不锈钢 产品 因为这种合金的抗腐蚀性能远超普通碳钢或铝复合材料。与需要频繁重新涂层的涂漆钢不同,不锈钢几乎无需任何维护,就能保持数十年的光滑金属光泽。这种韧性的背后,在于其化学性质以及表面形成的微观保护层。

1.1 铬和钝化层的作用

不锈钢的决定性元素是铬。根据国际标准,任何含有至少 10.5%铬 qualifies as stainless, but in practice, most structural or decorative grades use higher percentages. Once chromium is alloyed into steel and exposed to oxygen, it reacts almost instantly to form a thin, invisible oxide layer. This layer is not like the flaky rust that appears on carbon steel; instead, it is dense, adherent, and prevents oxygen and moisture from reaching the iron beneath. Engineers refer to it as the 被动层.

To understand how effective this passive layer can be, consider a simple comparison. Imagine two façade panels installed side by side on a coastal hotel: one made of painted mild steel, the other of 优质不锈钢板 用于建筑。六个月内,低碳钢墙面上会出现红色条纹,油漆也开始起泡。与此同时,不锈钢板仍然能反射阳光,几乎就像刚抛光过一样。这种差异完全是由于铬驱动的钝化膜。

The formation of this film follows a predictable process:

-

初次接触 – As soon as stainless steel is cut, rolled, or exposed to air, chromium at the surface reacts with oxygen.

-

氧化层形成 – 几秒钟内,就会形成一层稳定的氧化铬层,厚度只有几纳米。

-

Barrier Function – 该层密封了下面的金属,防止氧气或氯离子引发进一步的腐蚀。

-

Dynamic Balance – 如果表面被划伤,暴露的金属会再生新的氧化膜,保持持续的保护。

Different alloys have varying chromium content, which translates directly into different levels of resistance. For example, low-cost utility grades may have 11–12% chromium and work fine for indoor furniture, but marine-grade steels often exceed 22% chromium to handle salt spray. The chart below shows a simplified comparison of how chromium levels influence resistance:

| Material Type | Chromium Content | Resistance to Rust |

|---|---|---|

| 碳钢 | 0% | Very Low |

| 入门级不锈钢 | 10.5–12% | Moderate |

| Architectural Stainless Steel | 16–20% | High |

| Marine-Grade Stainless Steel | 22%+ | Excellent |

这种基本机制就是为什么不锈钢可以在如此苛刻的应用中受到信赖的原因,从暴露在持续潮湿环境中的地铁站到位于沿海气候中的标志性摩天大楼。

1.2 How Corrosion Resistance Works

The passive film on stainless steel is not static; it behaves like a living skin that can regenerate and repair itself. This self-healing property is the true secret behind its remarkable durability. If you scratch a 金属不锈钢板 used in cladding projects, the exposed area does not remain vulnerable for long. Within moments, as long as oxygen is present, chromium in the alloy reacts again and re-forms the protective oxide film.

为了了解这在实际建筑中是如何体现的,我们以新加坡滨海湾的一座高层建筑为例。开发商希望外墙能够抵御强烈的热带雨水、咸咸的海风和全年的高温。他们选择了 不锈钢外墙 system rather than painted aluminum. A decade later, the panels still shine with minimal discoloration, even though nearby structures using powder-coated finishes show visible wear. The reason is not luck but the consistent regeneration of the passive layer.

其工作原理涉及几个详细步骤:

-

中断 – Mechanical scratches, welding zones, or environmental abrasions expose raw metal.

-

氧气接触 – The exposed chromium atoms react with oxygen molecules in the environment.

-

电影续订 – 形成一层新的氧化铬,取代了屏蔽层受损的部分。

-

Continuity Restored – 该屏障再次阻挡了湿气和腐蚀剂。

This cycle can repeat indefinitely as long as the material contains sufficient chromium. That is why architectural engineers trust stainless steel for demanding projects like airport terminals, train stations, or civic centers that see constant human contact and environmental stress.

另一个优势是用途广泛。不锈钢可以制成厨房用的薄板、艺术博物馆用的抛光面板,或摩天大楼的重型覆层。每种应用都受益于相同的耐腐蚀原理。当与PVD涂层等现代表面处理技术相结合时,这种金属既耐用又具有装饰多样性,使建筑师不仅能够实现强度,还能获得设计灵活性。

In practice, this means a building fitted with stainless steel will not require costly repainting cycles every few years. Instead, maintenance is reduced to simple cleaning routines, often just rinsing with water or mild detergent. Over decades, the financial savings can be substantial compared to other materials that require frequent replacement or protective coatings.

2. When Does Stainless Steel Rust?

Although stainless steel is well known for its resistance to corrosion, there are specific conditions where even the highest grades can show signs of rust. Understanding these scenarios is essential for engineers, builders, and property owners who want their investments to stand the test of time. Below are the five most common situations where stainless steel becomes vulnerable.

2.1 氯化物暴露(盐水、化学物质)

The single most aggressive threat to stainless steel is chloride, found in saltwater, de-icing salts, and certain cleaning agents. Chloride ions can penetrate the passive layer and cause localized corrosion known as pitting. Unlike uniform rusting on carbon steel, pitting is far more dangerous because it creates deep holes that weaken the structure from within while leaving much of the surface seemingly unaffected.

一个很好的例子就是沿海建筑。迈阿密海岸线上的一家豪华酒店,其阳台上可能装有抛光的不锈钢栏杆。虽然它们乍一看完美无瑕,但每天暴露在咸咸的海水中,会逐渐形成细小的凹坑。如果不进行维护,这些凹坑会不断扩大,造成结构隐患和难看的污渍。

The progression usually follows this sequence:

-

Salt deposition 表面免受海浪或富含盐分的空气的影响。

-

Breakdown of the passive film 因为氯离子在微观点上取代了氧气。

-

Formation of pits,通常直到它们长大后才可见。

-

Spread of corrosion, which becomes difficult to stop once initiated.

为了直观地了解抗氯化物性能,这里有一个简单的比较:

| Stainless Steel Grade | Chloride Resistance | Typical Use Case |

|---|---|---|

| 304 | Moderate | 室内建筑、厨房 |

| 316 (with molybdenum) | High | 沿海建筑、泳池 |

| Duplex & Super Duplex | Very High | 海上平台、海堤 |

对于海边建筑,工程师很少推荐使用 316 级以下的材料,因为较便宜等级材料的前期节省通常会导致更高的更换成本。

2.2 高温环境

高温也会威胁不锈钢的耐久性。当暴露在高温下时,保护性的氧化铬层可能会变得不稳定。在500-800°C左右,某些牌号的不锈钢可能会发生一种称为敏化的现象,即碳化铬在晶界处形成,从而减少维持钝化膜所需的铬含量。

想象一下,一个发电厂的涡轮机外壳由不锈钢制成。随着废气日复一日地加热该结构,合金的某些部分开始变色。这种“热色”不仅仅是外观问题——它表明钝化层已变得脆弱,一旦设备冷却并形成冷凝水,就更容易受到腐蚀。

The degradation process unfolds in stages:

-

Thermal exposure 改变钢的微观结构。

-

Chromium depletion 靠近晶界会产生薄弱区。

-

氧化加厚, forming a brittle surface scale.

-

冷却后腐蚀 accelerates due to the compromised passive layer.

工业设计师通过选择310或446不锈钢等耐热等级来解决这个问题。这些合金即使在熔炉或排气系统中也能保持强度和耐腐蚀性,而其他合金在这些情况下会很快失效。

2.3 Scratches and Surface Damage

尽管钝化膜具有自愈能力,但较深的划痕或机械损伤仍可能为腐蚀提供根源,尤其是在与湿气或氯化物结合的情况下。例如,繁忙地铁站的不锈钢扶手经常受到接触、磨损和撞击。随着时间的推移,一些划痕会渗透得足够深,以至于环境无法快速补充钝化膜。

The risks become more pronounced when:

-

工具或尖锐物体 scrape the surface during installation.

-

清洁垫不当 (like steel wool) leave gouges.

-

Friction and abrasion 日常使用中会暴露出原始金属。

One case study comes from a public library renovation in northern Europe. Stainless panels installed in the lobby looked perfect initially. But within a year, cleaners using abrasive pads left streaks that later developed into rust spots, much to the architect’s frustration. Switching to non-abrasive cleaning materials stopped further damage, but the early patches had already stained the appearance.

This demonstrates that while stainless steel is tough, surface care remains crucial. Designers often specify finishes like brushed or bead-blasted textures that conceal minor scratches, reducing the risk of visible corrosion.

2.4 焊接和热影响区

Welding creates one of the most vulnerable spots on stainless steel. The intense localized heat alters the material’s microstructure, burning away some chromium and disrupting the passive layer. The zone adjacent to the weld—called the heat-affected zone (HAZ)—is particularly prone to rust if left untreated.

想象一下体育场内一个大型顶棚结构,长长的不锈钢管在高空焊接在一起。虽然抛光的部分看起来完美无瑕,但焊缝附近最终可能会出现锈迹斑斑的环状痕迹。这并非材料劣质的迹象,而是焊接过程中自然改变该部位化学性质的结果。

The welding corrosion cycle typically happens like this:

-

高温电弧 熔化并重新凝固接头。

-

碳化铬 沉淀,降低有效铬。

-

暖色调 forms—a discoloration visible as rainbow hues.

-

局部腐蚀 develops when the altered zones are exposed to weather.

熟练的焊接工人会通过使用合适的保护气体、限制热量输入以及进行焊后清洁(例如酸洗或钝化)来防止这种情况发生。这些步骤可以恢复钝化膜,确保焊接部件保持其长期的耐腐蚀性。

2.5 Low-Quality or Poor-Grade Material

Finally, not all stainless steels are created equal. Cheaper alloys with borderline chromium levels or impurities may pass as “stainless” but fail under real-world conditions. For example, some imported decorative panels used in low-budget shopping centers tarnish within months when exposed to cleaning chemicals.

迪拜的开发商就曾亲身经历过这种情况。他们在一个户外广场安装了廉价的不锈钢墙面,但由于合金质量不佳,不到一年就出现了锈迹。这些面板的铬含量仅略高于10.5%,成分不一致,因此不适合用于室外。

Here’s a comparison to illustrate the impact of quality:

| 等级或质量水平 | Chromium (%) | Performance in Harsh Environments |

|---|---|---|

| Substandard “budget” SS | 10.5–11 | Poor – prone to rust |

| 标准 304 | 18 | 良好 – 室内和温和的室外 |

| 海军陆战队 316 | 18+ 适合 | Excellent – coastal & chemical |

这凸显了从信誉良好的供应商采购的重要性。低成本材料的短期节省往往会导致昂贵的维修或更换。

3.Inox vs Stainless Steel: What’s the Difference (2025 Guide)

3.1 关键材料特性

当建筑师或建筑商谈论 inox, they’re simply using the European word for stainless steel, short for 防锈的, meaning “non-oxidizing.” Both terms point to the same family of corrosion-resistant alloys, but depending on the grade, performance can vary widely.

Every type of inox or stainless steel contains at least 10.5% chromium, which forms the passive layer that protects against rust. Grades like 304, 316, or 430 each include different amounts of nickel or molybdenum, shifting properties like strength and chloride resistance.

For example, 优质不锈钢板 in grade 304 are common in kitchens and food prep areas. Meanwhile, 316—sometimes called marine inox—adds molybdenum for superior performance against salty air, making it the material of choice for coastal buildings or marine railings.

Key factors that define these alloys include:

-

耐腐蚀 – Higher chromium and molybdenum content improve protection in harsh environments.

-

Mechanical Strength – Tensile strength ranges from 520 to 620 MPa for everyday grades, but duplex alloys go even higher.

-

Heat Resistance – Inox maintains its structure at temperatures up to 870°C, which is why it’s trusted in commercial kitchens and industrial plants.

-

Surface Finish – Brushed or mirror-polished finishes on inox give architects the clean, modern appearance that’s so popular in contemporary design.

3.2 Applications and Performance

The real test of inox versus stainless steel isn’t the terminology—it’s how each grade performs in practice. Take two real-life examples:

-

Residential Kitchen Countertop (304 stainless steel)

Families choose stainless steel counters because they are hygienic, non-porous, and simple to clean. Even after years of acidic spills like wine or vinegar, the surface maintains its sleek appearance. -

Hotel Lobby Exterior Wall (316 inox panels)

A five-star hotel in Singapore uses 316 inox cladding for its lobby entrance. Daily humidity, heavy rainfall, and strong chemical cleaners don’t damage the panels. Choosing 不锈钢外墙 solutions ensures the façade stays pristine for decades.

Here’s a clear side-by-side breakdown of how common grades compare:

| 特征 | 304 Stainless Steel (Standard) | 316 Inox (Marine Grade) |

|---|---|---|

| Chromium Content | 18–20% | 16–18% |

| Nickel Content | 8–10.5% | 10–14% |

| Molybdenum Content | None | 2–3% |

| Best Use Case | Kitchens, appliances | Coastal facades, marine use |

| 耐腐蚀 | High | Very High |

| Relative Cost | Lower | Higher |

Another scenario is residential kitchen countertops vs. hotel lobby façades, where the needs differ—durability indoors versus maximum weather resistance outdoors. This contrast shows why inox and stainless steel grades must be matched to the right application.

3.3 Cost and Availability

In 2025, the global demand for stainless alloys remains strong, which directly affects pricing and supply. The cost difference between inox and stainless steel isn’t in the name, but in the grade and finishing process.

-

Standard Options – Common grades like 304 are mass-produced and relatively inexpensive. Contractors often specify stainless steel metal plate for commercial kitchens or factory equipment where reliability meets budget.

-

Premium Grades – High-nickel or molybdenum-rich alloys, such as 316, cost more but offer decades of corrosion resistance, especially in outdoor architecture.

-

Regional Availability – In Europe, inox is the common trade term, while in North America, the market leans toward “stainless steel.” Imports from Asian suppliers keep both widely available.

-

Design Finishes – Polished or patterned 金属不锈钢板 panels cost more but are often used in luxury retail façades where appearance is paramount.

For buyers, the deciding factor often comes down to longevity versus upfront savings. Choosing higher-grade inox for exterior cladding prevents costly replacements later. And for trusted sourcing, many turn to established suppliers like pvdstainlesssteel, ensuring consistent quality and availability worldwide.

4. How to Prevent Stainless Steel from Rusting

Even though stainless steel is highly resistant to corrosion, no material is completely impervious. Exposure to chlorides, heat, scratches, or poor-grade alloys can trigger rust. Preventing corrosion is not just about buying quality material; it’s about understanding maintenance, protective measures, and proper material selection.

4.1 Proper Cleaning and Maintenance

Cleaning is the first line of defense against rust. Regular maintenance prevents contaminants like dirt, salt, or acidic substances from compromising the passive layer. For example, a coastal hotel using 不锈钢外墙 panels requires more frequent cleaning than an indoor installation because airborne salt deposits accumulate on the surface daily.

A proper cleaning routine involves:

-

Daily or Weekly Wipe-Down – Use soft cloths or microfiber towels with warm water. This removes dust, fingerprints, and light dirt.

-

Mild Detergent Wash – For more stubborn stains, mix neutral pH detergent with water. Avoid bleach or chlorides, as these attack the passive layer.

-

Rinse Thoroughly – Always rinse off soap residues. Leftover detergent can leave streaks or localized corrosion spots.

-

Drying – Use a soft towel or let the surface air dry to prevent water spots, which can accelerate pitting in sensitive grades.

-

Inspection – Regularly check high-contact areas, welds, and corners for signs of scratches or rust.

For interior applications, like kitchens or furniture, the same routine applies, but frequency may be lower. Homeowners using stain steel sheets for countertops often find that weekly cleaning suffices. In commercial environments, daily routines are necessary to maintain the metallic shine and corrosion resistance.

Need a surface that won’t brown or pit in salty or humid air? Check our 不锈钢板 with PVD anti-rust coating.