If you need a long-lasting and low-maintenance finish, go with PVD coating. It forms a harder, denser bond than electroplating and works best on 304 or 316 stainless steel used in building panels and furniture.

1. Understanding the Two Surface Finishing Methods

Stainless steel finishing methods play a huge role in how durable, stylish, and corrosion-resistant a surface becomes. Among the most used techniques are PVD coating a electroplating, both transforming plain metal surfaces into premium finishes with higher performance and aesthetic value. Designers often choose high-quality PVD coated stainless steel panels when working on hotel lobbies, luxury storefronts, or elevator interiors, because the finish stays vibrant and uniform even after years of exposure. These finishing technologies share a similar goal—enhancing protection and beauty—but they work through entirely different mechanisms.

1.1 What Is PVD Coating and How It Works

PVD stands for Physical Vapor Deposition, a process that uses vacuum technology to deposit thin, durable metal films onto a substrate. The operation typically includes several key steps:

-

Surface preparation, where the stainless steel is cleaned using ultrasonic or plasma methods to remove any impurities.

-

Evaporation and ionization, where metal materials such as titanium or zirconium are heated until they vaporize inside a vacuum chamber.

-

Film deposition, where those vaporized metal atoms condense and bond at the atomic level onto the steel surface.

The result is an extremely hard coating layer—typically 0.25 to 0.5 microns thick—with excellent adhesion and wear resistance. This process gives modern PVD stainless steel products an unmatched color stability, whether used for decorative stainless steel exterior wall cladding in commercial buildings or precision-engineered stainless steel sheet panels in architectural interiors. The coating’s hardness often exceeds 2,000 HV, far beyond what electroplating can reach. Because no harmful chemicals are used, PVD is also an environmentally friendly finishing choice.

Now, let’s see how electroplating differs in both process and performance.

1.2 What Is Electroplating and How It Works

Electroplating, by contrast, is a chemical deposition method. It uses an electrolyte solution containing metal ions (such as nickel or chromium) and an electric current to transfer those ions onto a stainless steel surface. The procedure involves:

-

Preparing the metal substrate by cleaning it in acid or alkaline solutions.

-

Submerging it into an electrolyte bath with the desired coating metal.

-

Applying a controlled current so that metal ions migrate and bond to the surface layer.

Electroplated finishes are often thicker, ranging from 5 to 25 microns, which helps improve corrosion resistance in mild conditions. However, the surface may be softer, and the coating adhesion depends heavily on preparation quality. Electroplating still finds wide use for stainless steel metal plates in decorative trims, kitchen fixtures, or automotive components, where cost efficiency and bright appearance matter more than extreme durability.

1.3 Key Differences in Process Mechanism

To better understand how both techniques perform in real-world applications, the following table compares their main process and performance parameters:

| Aspect | PVD Coating | Electroplating |

|---|---|---|

| Deposition Method | Physical vapor under vacuum | Electrochemical ion transfer |

| Coating Thickness | 0.25–0.5 μm | 5–25 μm |

| Hardness (HV) | 1800–2500 | 300–800 |

| Adhesion Strength | Atomic bonding | Mechanical bonding |

| Vplyv na životné prostredie | No toxic chemicals | Uses chemical baths |

| Color Range | Gold, black, bronze, rose, rainbow | Mostly silver or chrome |

| Trvanlivosť | Extremely high; suitable for exterior walls and high-traffic surfaces | Moderate; prone to wear over time |

These differences show why architects and manufacturers prefer PVD coating for long-term stainless steel applications, particularly in exterior façades and interior decorative elements. Its hardness, color diversity, and eco-friendly nature make it ideal for high-end architectural projects, while electroplating remains practical for lower-cost or short-term use.

2. Durability and Corrosion Resistance Comparison

When it comes to surface protection, durability is where the two coating methods truly separate. PVD coating forms a dense, molecular-level bond with stainless steel, creating a finish that is not only decorative but also extremely resilient against daily wear. That’s why designers and architects often specify zvyk PVD-coated stainless steel finishes for hotel exteriors, shopping malls, or high-end elevators — places that experience constant contact, sunlight, and moisture. Electroplated coatings, on the other hand, tend to rely on mechanical adhesion, which can chip or peel when exposed to repeated friction or cleaning chemicals.

2.1 Scratch and Wear Resistance

The scratch resistance of PVD-coated surfaces is remarkably higher because the coating hardness averages between 1800–2500 HV, while most electroplated finishes stay below 800 HV. That’s more than triple the durability in real-world conditions. In a luxury retail setting, for example, brushed stainless steel sheet panels used in display counters retain their clean, metallic sheen even after years of customer interaction, whereas electroplated layers can lose luster and show micro-scratches over time.

Below is a practical comparison of wear resistance under controlled conditions:

| Property | PVD Coating | Electroplating |

|---|---|---|

| Hardness (HV) | 1800–2500 | 300–800 |

| Odolnosť proti poškriabaniu | Excellent; resists abrasion and fingerprints | Moderate; easily scratched |

| Adhesion Strength | Atomic bonding | Mechanical bonding |

| Typical Use Case | High-contact architectural and decorative surfaces | Indoor fixtures with limited wear |

The superior microstructure of PVD coatings prevents metal-to-metal scuffing, making them ideal for vonkajšia stena z nehrdzavejúcej ocele panels and architectural accents exposed to urban environments.

2.2 Oxidation and Rust Protection

Oxidation is the biggest enemy of stainless steel metal plates in outdoor environments. PVD coatings form a stable, non-reactive barrier that isolates oxygen and moisture from the steel substrate. This makes them exceptionally resistant to rust, even in coastal or industrial settings with high humidity and salinity. Electroplating offers decent protection initially, but once a small crack or pinhole appears, corrosion spreads underneath the coating quickly.

In architectural projects like seaside resorts or public transportation hubs, pvdstainlesssteel surfaces maintain their color tone and gloss for years with minimal maintenance. The dense PVD layer also resists UV fading, which keeps gold, bronze, or black finishes consistent in appearance long-term.

2.3 Longevity Under Harsh Environments

Longevity is where PVD coating outperforms electroplating by a wide margin. In accelerated salt-spray tests, PVD-coated stainless steel showed over 1,000 hours of corrosion resistance without visible damage, while electroplated surfaces started showing oxidation spots within 120–300 hours. That kind of endurance is why architects trust PVD for skyscraper façades, outdoor sculptures, and transit station interiors.

When used on decorative stainless steel exterior wall cladding, PVD finishes stay intact under constant temperature shifts—from freezing winters to scorching summer heat—without peeling or color degradation. Electroplated layers often require recoating every few years, especially in regions with acid rain or pollution.

This level of strength and environmental tolerance sets the stage for understanding not just durability, but how both methods differ in appearance and color stability, which we’ll explore next.

3. Appearance and Color Options

While both finishing methods can enhance the visual appeal of stainless steel, the color range, brightness, and long-term stability between PVD coating and electroplating are vastly different. For architects and designers, this often determines which method fits the project’s aesthetic vision. In luxury hotels, airports, or shopping malls, decorative PVD stainless steel products offer richer tones, deeper reflections, and unmatched color consistency across large surface areas — something traditional plating can rarely achieve.

3.1 Visual Finish and Reflectivity

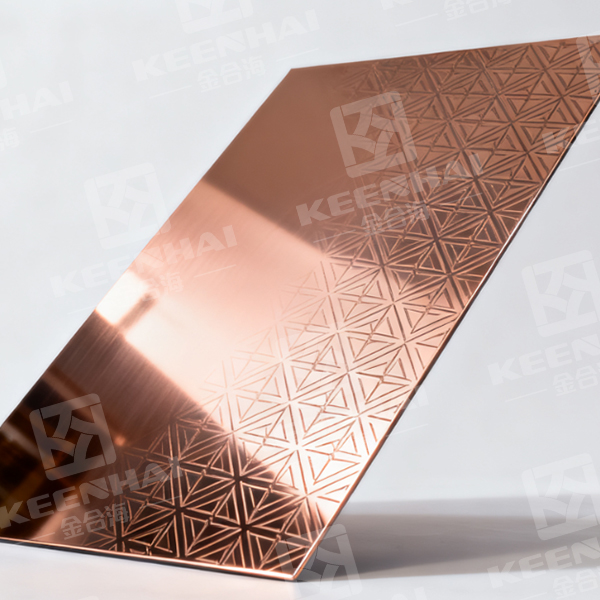

PVD coating creates a mirror-smooth surface finish with micro-level precision, allowing reflections to appear crisp and uniform. Depending on the metal source (like titanium, zirconium, or chrome), PVD can achieve gold, rose gold, bronze, black, or even rainbow finishes without fading. This is why stainless steel sheet panels used in high-end lobbies or jewelry display areas often feature PVD coating — they maintain their brilliance under different lighting conditions.

Electroplating, on the other hand, delivers a bright but somewhat limited metallic tone, mostly silver or chrome. Its reflective surface may look impressive at first, but oxidation gradually dulls the shine, especially under UV exposure or humid conditions.

3.2 Color Variety and Consistency

Color consistency is a major reason why pvdstainlesssteel has become the preferred choice in modern architecture. The PVD process deposits thin atomic layers that ensure uniform color distribution across large batches of stainless steel metal plates, even when used on curved or irregular panels. This level of precision enables seamless installations — for example, a hotel entrance with continuous bronze panels can appear as one cohesive structure without visible tone variations.

Electroplated surfaces, by contrast, often suffer from uneven color or brightness due to inconsistent current flow during plating. As a result, the same batch might show slight tonal differences, making it harder to achieve perfect visual alignment in large-scale architectural projects.

3.3 Aesthetic Retention Over Time

Long-term visual performance is another area where PVD coatings dominate. Even after 10+ years of outdoor exposure, PVD finishes maintain over 95% of their original gloss. The color remains stable because it’s not a superficial pigment—it’s a bonded metallic layer. This gives designers the freedom to use PVD-coated Vonkajší obklad stien z nehrdzavejúcej ocele on façades, columns, and decorative trims without worrying about color fading or peeling.

In contrast, electroplated coatings may tarnish or develop cloudy patches within a few years, especially when exposed to urban pollution or cleaning chemicals. Maintenance teams often need to re-polish electroplated parts to restore brightness, which adds long-term costs.

The visual endurance and color versatility of PVD make it ideal for premium architectural environments where both beauty and consistency matter. Up next, we’ll look at how environmental impact and maintenance requirements differ between the two finishing technologies — a crucial factor for sustainable and long-term material selection.

4. Environmental and Maintenance Factors

Finishing choices matter not only for looks and durability but also for long-term upkeep and environmental footprint. PVD coating eliminates the need for large chemical baths and generates far less hazardous waste than traditional electroplating, which uses concentrated acid and metal-containing electrolyte solutions. From a facilities manager’s point of view, this means lower disposal costs and fewer regulatory headaches over time. At the same time, maintenance crews care most about how easy surfaces clean and how often they require rework — so let’s break down both processes from cleaning, lifecycle, and environmental angles.

4.1 Eco-Friendliness of Each Process

PVD stands out for lower environmental impact because it uses vacuum deposition and solid metal sources rather than liquid baths. Electroplating requires:

-

Pre-treatment acids and alkalis for degreasing and activation.

-

Electrolyte baths containing metal salts (nickel, chromium, etc.).

-

Post-treatment rinses and passivation, producing metal-bearing wastewater that needs neutralization and precious-metal recovery.

Those three steps create hazardous effluent and require continuous monitoring. In contrast, PVD needs energy (vacuum pumps and power for evaporation) but produces negligible liquid waste. From a compliance standpoint, PVD reduces chemical handling risks, lowers hazardous waste volumes, and often simplifies permits for shop operations. That environmental advantage makes PVD a strong choice for sustainable building projects.

4.2 Cleaning and Maintenance Requirements

Maintenance teams always ask: what cleans easiest and lasts longest? Here’s a practical, field-ready guide:

-

Daily/regular cleaning — Use a soft microfiber and mild, pH-neutral detergent for both PVD and electroplated surfaces. Avoid abrasive pads.

-

Stain removal — For stubborn grime, apply a non-abrasive cream cleaner and rub gently following the grain direction.

-

Pravidelná kontrola — Every 6–12 months, check for localized wear, especially around edges, seams, and fasteners.

PVD surfaces generally require less frequent rework because the hard, bonded layer resists scratching and cleans well without polishing. By contrast, electroplated finishes often need re-polishing or localized re-plating after heavy abrasion or chemical exposure. From an operations budget perspective, PVD typically lowers lifecycle maintenance costs thanks to reduced polishing frequency and fewer repairs.

4.3 Surface Stability After Long-Term Use

Longevity under real-world maintenance regimens matters more than lab numbers. Below is a concise comparison of environmental and maintenance performance metrics that designers and facility managers reference when choosing finishes:

| Metric | PVD Coating | Electroplating |

|---|---|---|

| Typical Waste Profile | Low liquid hazardous waste; electricity-intensive | High-volume chemical baths; metal-bearing wastewater |

| Routine Cleaning Frequency | Quarterly to biannual deep-clean; light wipes monthly | Monthly polishing in high-traffic areas |

| Rework / Recoat Interval | 8–20+ years depending on use | 3–7 years in moderate-to-high wear settings |

| Disposal / End-of-Life Concerns | Easier — substrate remains stainless steel | Requires contaminated waste handling if plating peels |

| Operational Safety | Lower chemical exposure for workers | Higher risk from acids/alkalis and metal salts |

In short, PVD reduces environmental burden and often cuts maintenance time and cost, especially on architectural elements exposed to the elements or frequent human contact. That said, choose electroplating only when initial budget constraints or very specific surface appearances drive the decision.

Next, we’ll examine appearance and color stability in service conditions and tie that back to realistic product and design choices so you can pick the best finish for your project.

5. Cost, Efficiency, and Application Suitability

While both PVD coating a electroplating enhance stainless steel appearance and protection, their cost structures, efficiency, and best-fit applications differ sharply. Understanding these differences is critical for designers, architects, and manufacturers optimizing budgets without compromising performance.

5.1 Manufacturing and Operational Costs

The biggest cost driver lies in setup and throughput. Electroplating has lower initial equipment costs — tanks, rectifiers, and basic chemical control systems typically run 30–50% cheaper than PVD chambers. However, PVD quickly offsets that through lower operating and waste-handling costs.

Typical figures:

-

Electroplating – $0.3–$0.8 per square foot, but add 20–30% for post-treatment, polishing, and waste management.

-

PVD coating – $0.8–$1.5 per square foot, yet maintenance-free for up to 15 years.

When production volume exceeds 10,000 ft² annually, PVD often becomes more cost-efficient due to reduced rework and labor. Factories targeting premium architectural panels or decorative stainless fixtures gain faster payback from PVD’s longevity and consistency. For high-volume, low-margin consumer goods, electroplating may remain viable when appearance outweighs lifetime durability.

5.2 Suitable Stainless Steel Grades for Each Method

Both processes work with most stainless alloys, but their performance varies by grade hardness and surface energy.

| Stainless Grade | Recommended Process | Reason |

|---|---|---|

| SUS 201 / 202 | Electroplating | Lower nickel content; better adhesion in chemical baths |

| SUS 304 / 316 | PVD Coating | High corrosion resistance supports vacuum adhesion and color stability |

| 430 (Ferritic) | PVD Coating | Handles high-temperature deposition; better long-term gloss retention |

PVD bonds more effectively with high-nickel or ferritic stainless steels, forming dense, uniform layers that resist salt spray and fingerprints. Electroplating, on the other hand, often struggles with uniform coverage on 316-grade surfaces without aggressive pre-treatment. In short, for marine, luxury architectural, or food-grade applications, PVD on 304 or 316 stainless delivers unmatched results, while electroplating suits utility or decorative hardware where cost per unit dominates.

5.3 Best Applications by Industry or Product Type

Choosing between the two comes down to how and where the stainless steel will live. Here’s how industries typically decide:

| Industry | Recommended Finish | Typical Products |

|---|---|---|

| Architecture & Interiors | PVD Coating | Facade panels, elevator doors, stainless steel wine cabinets, handrails |

| Consumer Electronics | PVD Coating | Device casings, trim frames |

| Automotive & Hardware | Electroplating | Hinges, fasteners, decorative knobs |

| Commercial Kitchen Equipment | PVD Coating | Backsplashes, handles, refrigeration panels |

| Mass-Produced Utilities | Electroplating | Bathroom accessories, small brackets |

PVD dominates premium sectors due to its hardness (HV 1800–2500) and vibrant, fade-resistant colors, whereas electroplating still wins in low-cost, high-volume segments.

If you manufacture architectural-grade stainless products like wine display racks or sunroom trims, PVD is the smarter, longer-lasting investment.

In the end, the choice between PVD coating and electroplating depends on what you value more—longevity, color consistency, and eco-efficiency alebo lower upfront cost and mass production speed. For architectural, luxury, and design-driven stainless steel applications, PVD finishes clearly outperform traditional plating, offering up to three times the hardness and zero chemical waste. If you’re sourcing custom PVD-coated stainless steel panels or decorative metal products, explore the full range at pvdstainlesssteel.com — where precision craftsmanship meets modern surface technology.